Henwi Automatic 4 Piston Paste Liquid Filling Machine

- Cena

- $8,800

The automatic servo piston filling machine is a highly efficient and precise filling device widely used in industries such as food, pharmaceuticals, daily chemicals, and chemicals. It is capable of handling liquids, pastes, and high-viscosity materials. Its core advantage lies in its servo motor drive, which ensures high precision and flexibility during the filling process.

### 1. Working Principle

This equipment operates based on the volumetric filling principle, with the servo motor driving the piston to complete the suction and discharge processes:

- **Suction Process**: The servo motor retracts the piston, creating negative pressure that draws the material into the piston chamber.

- **Discharge Process**: The servo motor advances the piston, pushing the material through the discharge valve into the container.

The servo system precisely controls the stroke and speed of the piston, ensuring consistency and accuracy in each filling cycle.

### 2. Servo Control System

The servo control system is the core of the filling machine, featuring:

- **High Precision Control**: Filling volume accuracy is maintained within ±0.3% to ±0.5%.

- **Programmable Control**: Users can set filling parameters such as speed and volume through a PLC (Programmable Logic Controller) and HMI (Human-Machine Interface), allowing for personalized adjustments.

- **Multiple Filling Modes**: Supports various filling methods, including volumetric, constant speed, and pulse filling, to meet different production needs.

### 3. Structural Features

- **Filling Head and Flow Path System**: Made from hygienic stainless steel, the filling head is designed with anti-drip features to ensure a clean and contamination-free filling process. The internal structure minimizes foaming, particularly useful for foamy liquids.

- **Piston System**: Utilizes a high-precision piston that works in conjunction with the cylinder, allowing for accurate volume control. The piston diameter and stroke can be customized based on specific filling requirements.

- **Sterile Design with CIP/SIP Cleaning Functions**: The material contact parts are designed for easy disassembly and cleaning, and can be equipped with automatic cleaning (CIP) and sterilization (SIP) systems to ensure a sterile production environment, compliant with GMP (Good Manufacturing Practice) and HACCP (Hazard Analysis Critical Control Point) standards.

### 4. Applicable Material Range

- **Liquid Materials**: Such as water, juice, milk, sauces, and oils.

- **Semi-fluid and High-viscosity Materials**: Including creams, toothpaste, sauces, honey, jams, shampoos, and lubricants.

- **Materials with Particles**: Specially designed filling valves and wide flow paths allow for the filling of materials containing solid particles or suspensions, such as fruit pulp beverages, ketchup, and sesame paste.

### 5. Automation and Intelligent Features

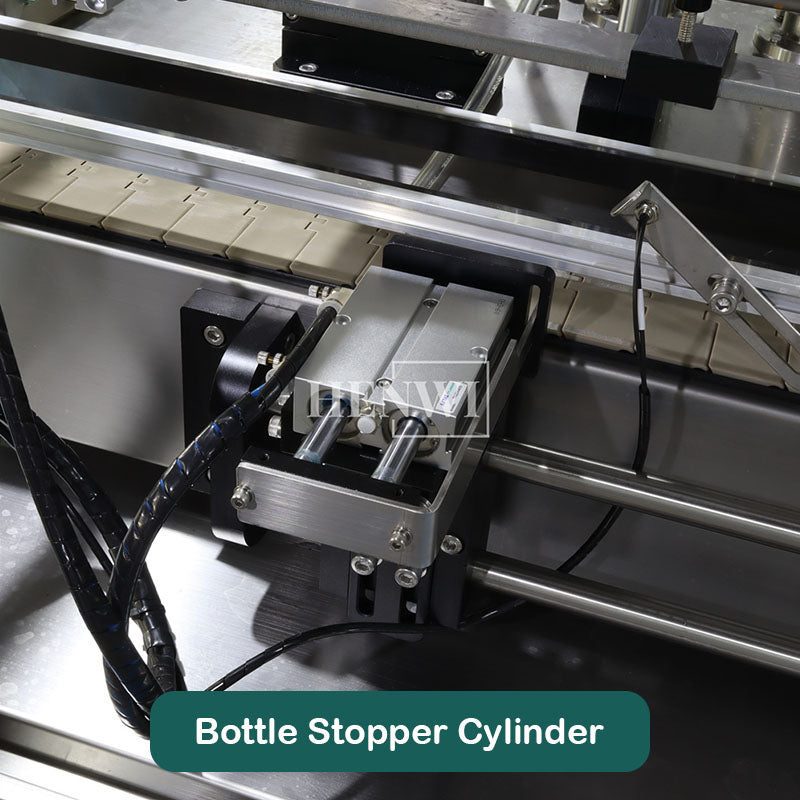

- **Automatic Detection System**: Equipped with photoelectric sensors or machine vision systems to automatically detect bottle presence, positioning, and defects, ensuring filling only occurs when the bottle is properly positioned, thereby preventing waste.

- **Multi-head Filling with Synchronous Control**: Typically configured with 2 to 12 filling heads, the number of heads can be selected based on production line speed and output requirements. Each head can be controlled independently to ensure precise filling amounts for each bottle, accommodating batch production needs.

- **Production Data Recording and Traceability**: The equipment can monitor and record key data such as filling volume, production speed, and errors in real time, providing data export and remote monitoring functions for quality control and traceability during production.

### 6. Safety and Maintenance

- **Safety Protection Features**: The servo piston filling machine is equipped with multiple safety measures, such as overload protection, emergency stop buttons, and safety covers to ensure the safety of operators and the equipment.

- **Fault Diagnosis and Alarm Functionality**: The system conducts real-time monitoring, and when abnormalities occur, it automatically alarms and displays fault codes to help operators quickly locate and resolve issues.

- **Ease of Maintenance**: Due to the high-precision design of the servo system and mechanical structure, the equipment operates more reliably, reducing downtime caused by mechanical wear. Most components are modular, making them easy to disassemble and replace, lowering maintenance costs.

### 7. Adjustability of Filling Precision and Speed

The advantages of the servo motor not only include high precision control but also allow for highly adjustable filling speeds. Users can flexibly adjust the filling speed and acceleration/deceleration curves according to the characteristics of the materials and production needs, ensuring an efficient and stable filling process. For example:

- For liquid materials with good flow properties, the filling speed can be increased to enhance production efficiency.

- For higher viscosity materials or liquids prone to foaming, the filling speed can be decreased to ensure filling quality.

Application

Parameter

| Number of filling heads: 4 |

| Filling range: A.100-1000ml; B.300-3000ml; C.500-5000ml; |

| Filling speed: 1200-2400 bottles/hour |

| Measuring accuracy: ±0.5% |

| Power: 6KW |

| Voltage: 380V |

| Working air pressure: 0.6-0.7Mpa |

| Air consumption: 4-6m³/min |

| Machine size: 4000*1300*2100mm |

| Machine weight: 600kgs |

| PLC: Mitsubishi |

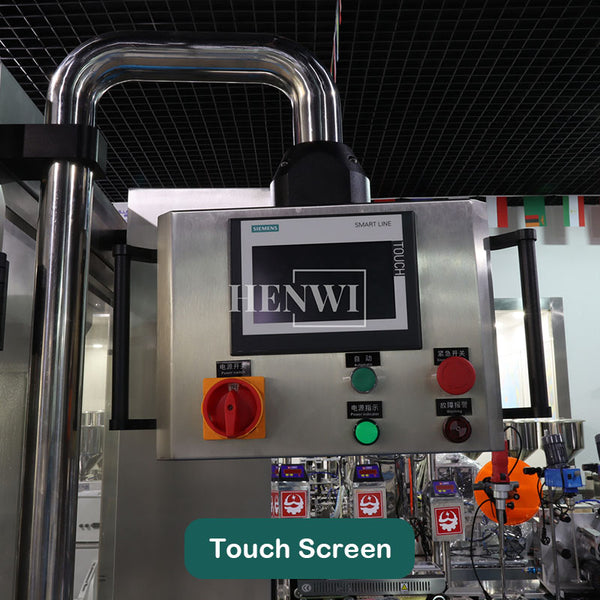

| Touch screen: Simens |

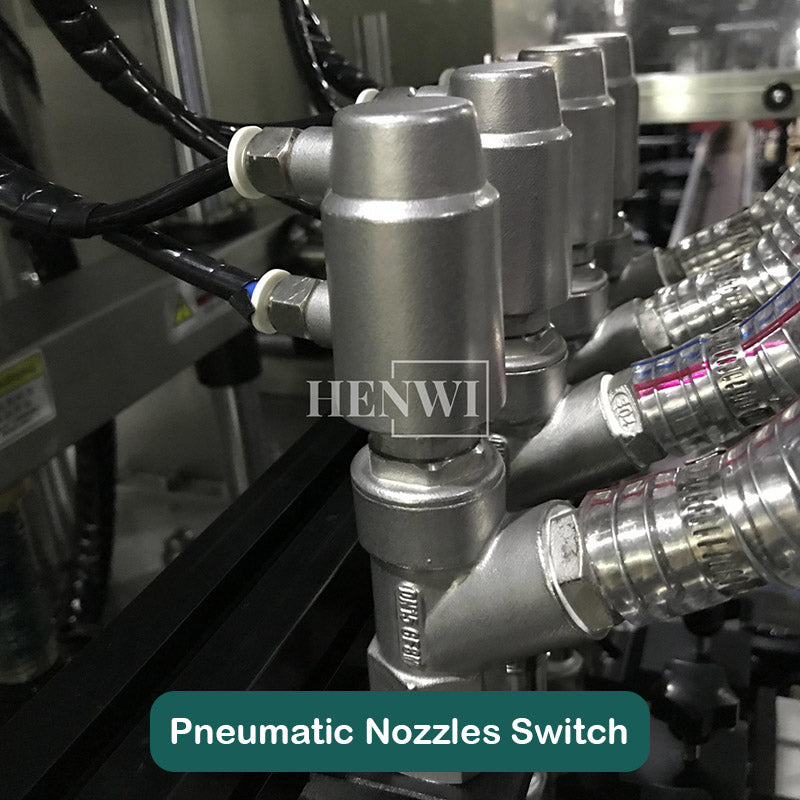

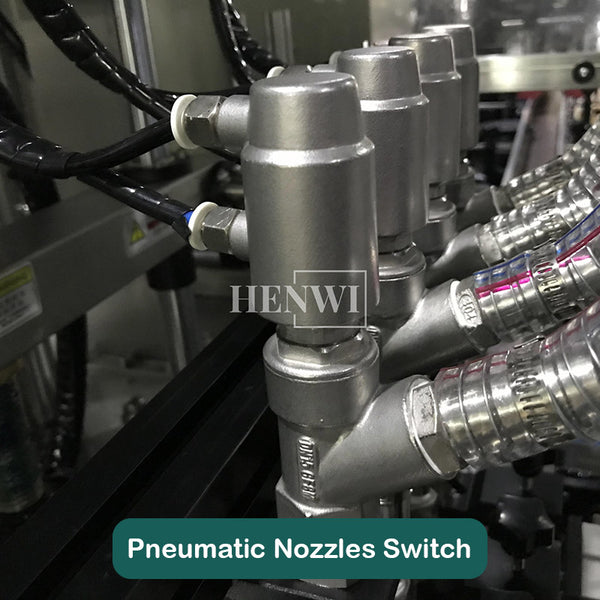

| Pneumatic components: AirTac Taiwan |

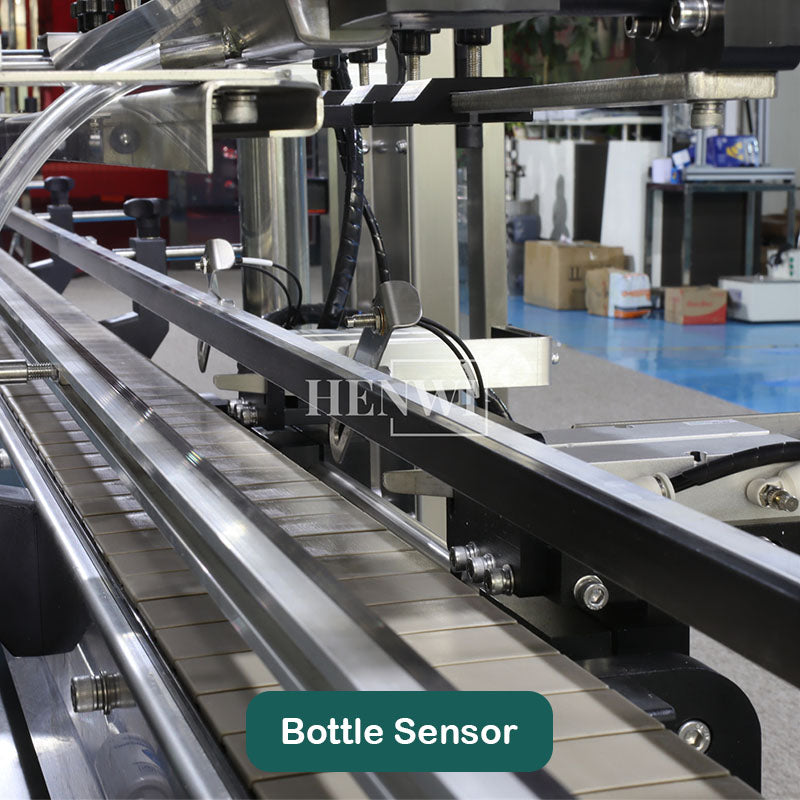

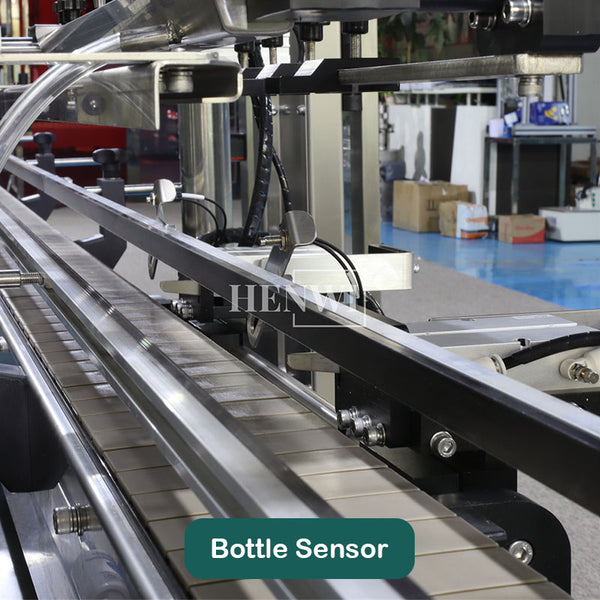

| Sensor: KEYENCE |

| Servo system: TECO,China |

| Motors: ZD,China |

| Relay: Schneider, France |

Anti-Drip Filling Nozzle

The anti-drip filling nozzle is a critical component of the automatic servo piston filling machine, designed to prevent liquid or paste from dripping after the filling process. This feature is essential for maintaining cleanliness and preventing material waste. Below are the key characteristics and functions of the anti-drip filling nozzle:

#### 1. **Design and Material**

- **Hygienic Construction**: The nozzle is made from high-grade stainless steel 316L to ensure hygiene and resistance to corrosion. This is particularly important for industries like food and pharmaceuticals.

- **Streamlined Shape**: The nozzle is designed with a streamlined shape that minimizes the chances of liquid adhering to its surface, reducing the likelihood of drips.

#### 2. **Operational Mechanism**

- **Gravity and Pressure Control**: The anti-drip nozzle operates by controlling the flow of material using gravity and back pressure. It prevents any residual liquid from escaping the nozzle after filling.

- **Quick Shut-Off Feature**: Many anti-drip nozzles are equipped with a quick shut-off mechanism that stops the flow of material as soon as the filling process is completed. This is often achieved through a mechanical or pneumatic control system.

Filling nozzle automatic lifting device (cylinder)

Automatic telescopic receiving chute

PLC Touchscreen

The PLC touchscreen is a crucial control component of the automatic servo piston filling machine, providing an intelligent and user-friendly operating experience.

1. **Intuitive User Interface**: The touchscreen features a color display with a user-friendly interface, allowing operators to easily set and adjust various parameters such as filling volume, filling speed, and servo motor operating modes through simple taps and swipes.

2. **Parameter Setting and Adjustment**: The touchscreen enables precise setting of filling parameters, including the filling volume per cycle, filling time, and speed. Operators can quickly adjust these settings based on production needs, ensuring flexibility to handle different batches.

3. **Real-Time Monitoring and Display**: The operational status of the machine is displayed in real-time on the touchscreen, including current filling speed, filling volume, production batch information, and equipment faults, making it convenient for operators to monitor machine performance.

4. **Fault Diagnosis Function**: The touchscreen features self-diagnosis and alarm capabilities. If a fault occurs, the system automatically displays alarm information and the cause of the issue, helping operators quickly identify and resolve problems, thus minimizing downtime.

5. **Data Storage and Recall**: The touchscreen has storage functions that allow different filling parameter settings to be saved. This facilitates quick retrieval of pre-set parameters when switching between products, improving efficiency and reducing the need for repetitive setups.

6. **Multi-Language Support**: Typically, the touchscreen supports multiple language settings, allowing operators to choose the appropriate language, enhancing ease of use and accuracy in operations.

Electrical Box

The electrical system is the core control unit of the automatic filling machine, responsible for coordinating various electrical components and functional modules to achieve automated operations and precise control.

1. **PLC Control System**: The entire machine is controlled by a Programmable Logic Controller (PLC) as the central control unit. The PLC processes signals from sensors, actuators, and the human-machine interface (HMI) touchscreen, managing real-time control of detection, filling, conveying, and other operations.

2. **Servo Drive System**: The servo motor is critical for controlling filling precision and speed. The servo driver connects to the PLC, receiving signals and accurately controlling the motor's speed and position.

3. **Sensor System**: The electrical system is equipped with multiple sensors, such as liquid level sensors and position sensors, for real-time monitoring of the machine's status. Liquid level sensors manage material replenishment, while position sensors control the accurate movement of the filling head.

4. **Frequency Converter**: The frequency converter adjusts motor speed, especially when flexible control of filling or conveying speed is required. It ensures smooth speed regulation, protecting the motor and extending the machine's lifespan.

5. **Power Management System**: The machine includes a reliable power supply and protection system, effectively controlling startup and shutdown while preventing damage to electrical components from current overload or voltage fluctuations. The electrical cabinet houses air switches, overload protectors, and other safety devices to ensure operational safety.

6. **Emergency Stop System**: The machine is equipped with an emergency stop button. In case of an emergency, operators can press the button to immediately cut off all power, halting the machine and preventing accidents. This system enhances the machine's safety and reliability.

7. **Automatic Alarms and Fault Diagnosis**: The electrical system integrates automatic alarm and fault diagnosis functions. If an abnormality or malfunction occurs, the system alerts the operator via the touchscreen or an audible alarm, displaying detailed fault information to help quickly identify and address the issue, minimizing downtime.

PLC

Servo Piston Cylinder

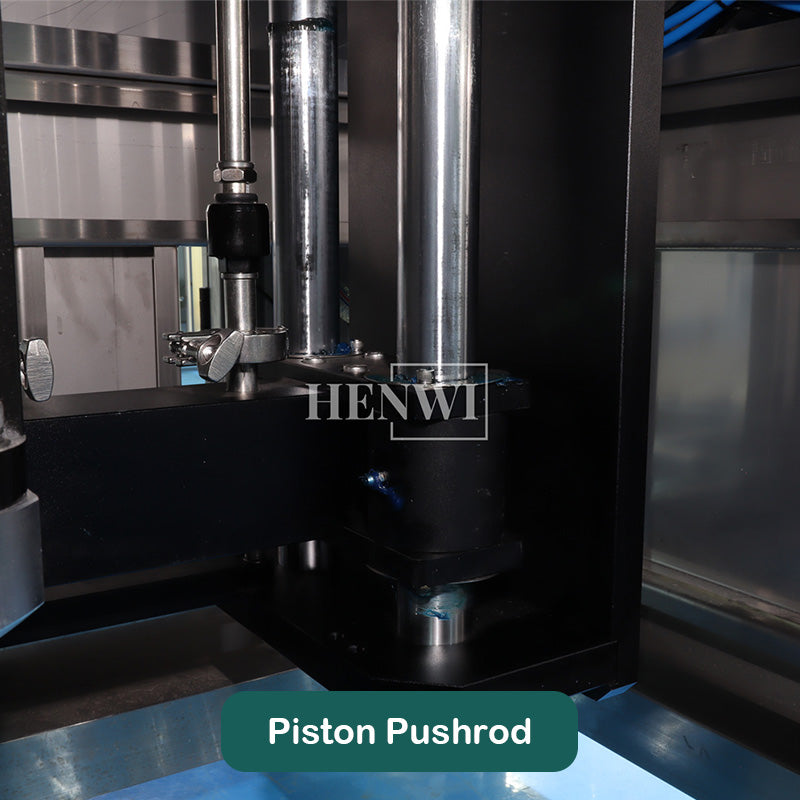

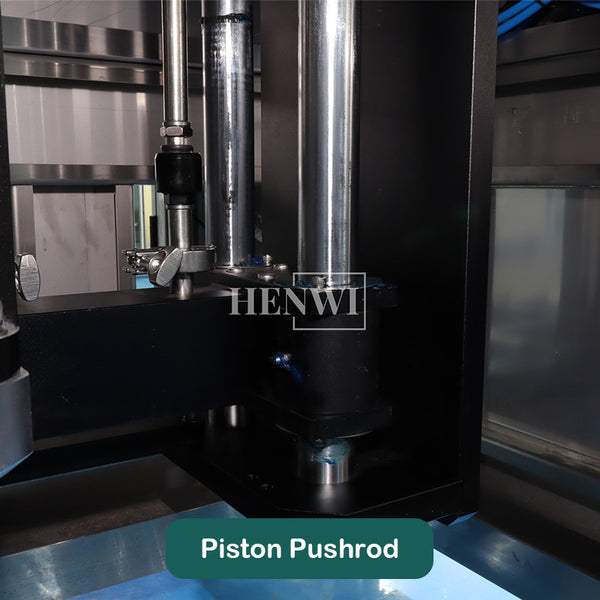

The servo piston cylinder is a crucial component of the automatic servo piston filling machine, playing a key role in achieving accurate and efficient filling operations.

#### 1. **Construction and Material**

- **High-Quality Materials**: The cylinder is made of high-grade stainless steel 316L to ensure durability, corrosion resistance, and compliance with hygiene standards required in food, pharmaceutical, and cosmetic industries.

- **Precision Engineering**: The internal surfaces of the cylinder are finely machined to provide a smooth finish, reducing friction between the piston and cylinder wall, which enhances the accuracy of the filling process.

#### 2. **Functionality**

- **Piston Movement**: The servo piston cylinder operates by converting the rotary motion of the servo motor into linear motion. This allows the piston to move back and forth within the cylinder, facilitating the suction and discharge of materials.

- **Suction Stroke**: When the servo motor retracts the piston, it creates a vacuum that draws the material into the cylinder from the hopper or feed tank.

- **Discharge Stroke**: When the servo motor advances the piston, it forces the material out through the discharge nozzle into the container.

#### 3. **Precision Control**

- **Accurate Volume Control**: The cylinder’s design allows for precise control of the volume of material dispensed, with filling accuracy typically maintained within ±0.3% to ±0.5%. The stroke length and piston speed can be programmed based on the specific filling requirements.

- **Adjustable Stroke Length**: The stroke length can be easily adjusted to accommodate different filling volumes, making the system highly versatile for various product sizes and types.

#### 4. **Performance Features**

- **Rapid Response**: The integration of a servo motor enables quick and accurate positioning of the piston, allowing for high-speed filling without sacrificing precision.

- **Reduced Pulsation**: The servo piston cylinder is designed to minimize pulsation during filling, ensuring a smooth and consistent flow of material, which is particularly important for high-viscosity products.

#### 5. **Hygiene and Maintenance**

- **Easy Cleaning and Maintenance**: The design of the servo piston cylinder typically allows for easy disassembly for cleaning and maintenance. Many systems are compatible with Clean-In-Place (CIP) processes to ensure sanitary conditions without extensive manual cleaning.

- **Durable Construction**: The use of high-quality materials and precision engineering contributes to the long lifespan of the cylinder, reducing the need for frequent replacements and repairs.

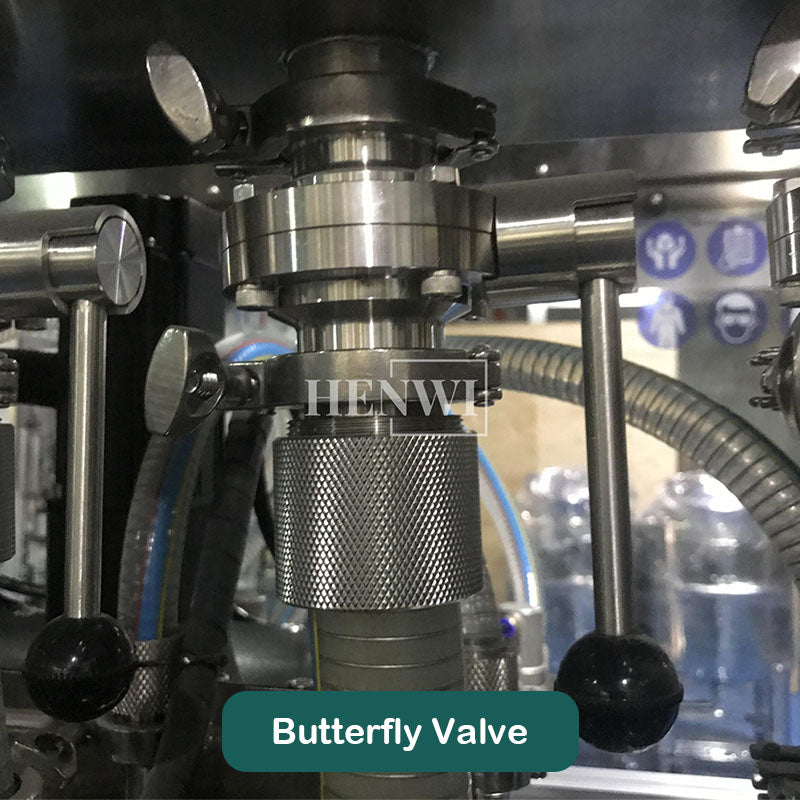

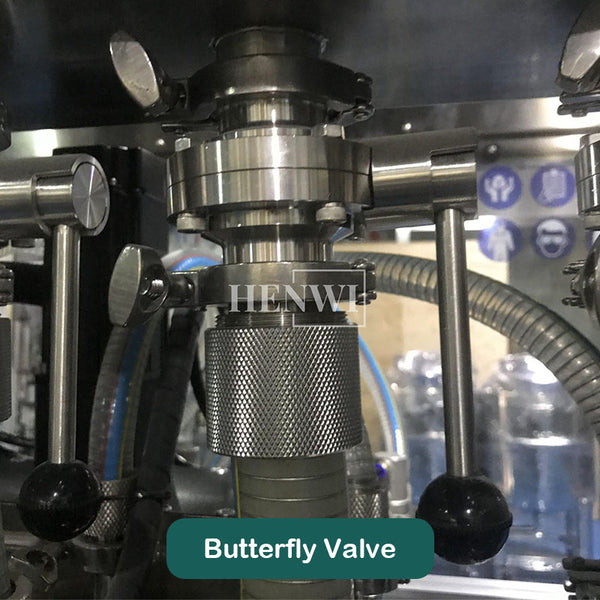

Pneumatic rotary valve for cylinder

Servo Motor

Servo Driver

Drive belt

With limit screw lifting drive piston

Conveyor Belt

The conveyor belt is an integral component of the automatic servo piston filling machine, facilitating the efficient transport of containers throughout the filling process.

#### 1. **Construction and Material**

- **Durable Materials**: The conveyor belt is made from high-quality materials such as PVC, which provide excellent resistance to wear, chemical exposure, and varying temperature conditions.

- **Modular Design**: Many conveyor belts are designed with modular components, allowing for easy customization and flexibility in configuration according to the layout of the production line.

#### 2. **Functionality**

- **Container Transport**: The primary function of the conveyor belt is to move containers (such as bottles, jars) into position for filling and out after the filling process is complete. This automated movement enhances workflow efficiency.

- **Synchronization with Filling Process**: The conveyor belt is synchronized with the filling machine's operation to ensure that containers are precisely positioned under the filling nozzles, minimizing any delays and reducing the risk of spills or misalignment.

#### 3. **Design Features**

- **Adjustable Speed**: The conveyor speed can be adjusted to match the filling rate, ensuring optimal coordination between the filling and conveying processes. This adjustability helps maintain production efficiency.

#### 4. **Performance and Reliability**

- **Continuous Operation**: The conveyor belt system is designed for continuous operation, providing a reliable transport mechanism that minimizes downtime during production.

- **Low Maintenance**: Modern conveyor belts are engineered for low maintenance requirements, featuring self-lubricating bearings and robust construction that reduce the need for frequent repairs.

Conveyor speed inverter

Conveyor motor

200L Stainless Steel 316 Hopper with Automatic Refill

The 200L stainless steel 316 hopper with automatic refill is a critical component in the automatic servo piston filling machine setup. It serves as a storage and supply unit for bulk materials, ensuring a continuous and reliable flow of product during the filling process.

#### 1. **Construction and Material**

- **High-Quality Stainless Steel 316**: The hopper is constructed from stainless steel 316, known for its superior corrosion resistance and durability, making it suitable for demanding environments, especially in food and pharmaceutical applications.

- **Robust Design**: The design of the hopper includes reinforced joints and smooth internal surfaces to withstand the pressure of the stored material and facilitate easy cleaning, adhering to hygiene standards.

#### 2. **Capacity and Dimensions**

- **200L Capacity**: The hopper has a capacity of 200 liters, providing ample storage for a variety of materials, including liquids, pastes, , which reduces the need for frequent refilling and enhances production efficiency.

#### 3. **Automatic Refill Mechanism**

- **Continuous Supply**: The automatic refill system ensures that the hopper is continuously supplied with material from a bulk storage tank or silo. This is achieved through level sensors that monitor the material level in the hopper and trigger the refill process when necessary.

#### 4. **Performance Features**

- **Easy Access for Maintenance**: The hopper is designed with access points for easy cleaning and maintenance, including removable covers, which facilitate thorough inspections and sanitation.

Material level sensor

Material tank drain

Bottle Detect Sensor

The Keyence bottle detection photoelectric sensor in the filling machine is crucial for accurately detecting the presence, position, and movement of bottles, ensuring the smooth operation of the automated filling process.

1. **High-Precision Bottle Detection**: The sensor can quickly and accurately detect whether a bottle is in place, ensuring each bottle stops precisely at the filling position, preventing filling errors or material waste due to missing or misaligned bottles.

2. **Non-Contact Detection**: Utilizing optical sensor technology, the Keyence sensor detects bottles without physical contact, avoiding the wear or contamination that may occur with traditional mechanical detection methods. This is especially beneficial for high-speed automated lines and industries with stringent hygiene requirements, such as food and pharmaceuticals.

3. **High Response Speed**: As filling lines often operate at high speeds, the fast response time of the Keyence sensor ensures that bottles are detected promptly, with real-time feedback to the PLC system for precise filling actions. Even when bottles move quickly, the sensor can reliably detect them.

4. **Stability and Interference Resistance**: The Keyence sensor is highly resistant to environmental interference, allowing stable operation in complex production environments. It avoids detection errors caused by factors like ambient light, dust, or varying bottle transparency. The sensor can accurately detect even transparent or reflective bottles.

5. **Multiple Detection Modes**: The Keyence sensor supports various detection modes, such as through-beam or reflective, and can be configured based on the specific requirements of the filling line. This flexibility accommodates different bottle sizes, shapes, and materials, ensuring adaptability in the filling process.

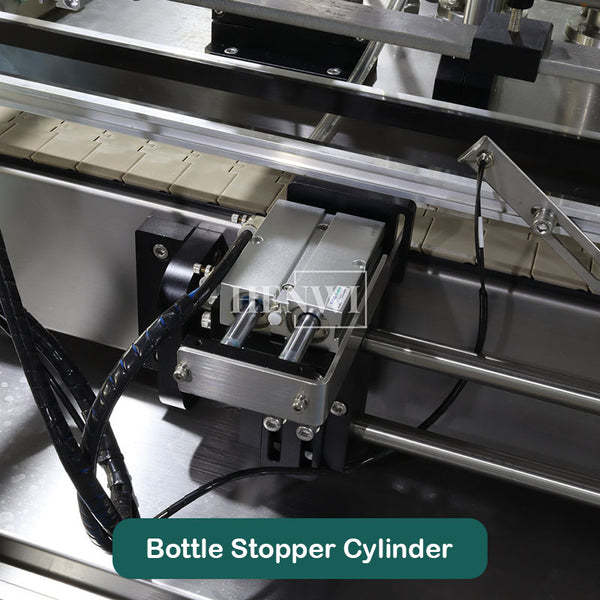

Bottle Stopper

Air pressure regulating valve

Spare parts

Welding

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.