Automatic cartoning machine

- Cena

- $21,000

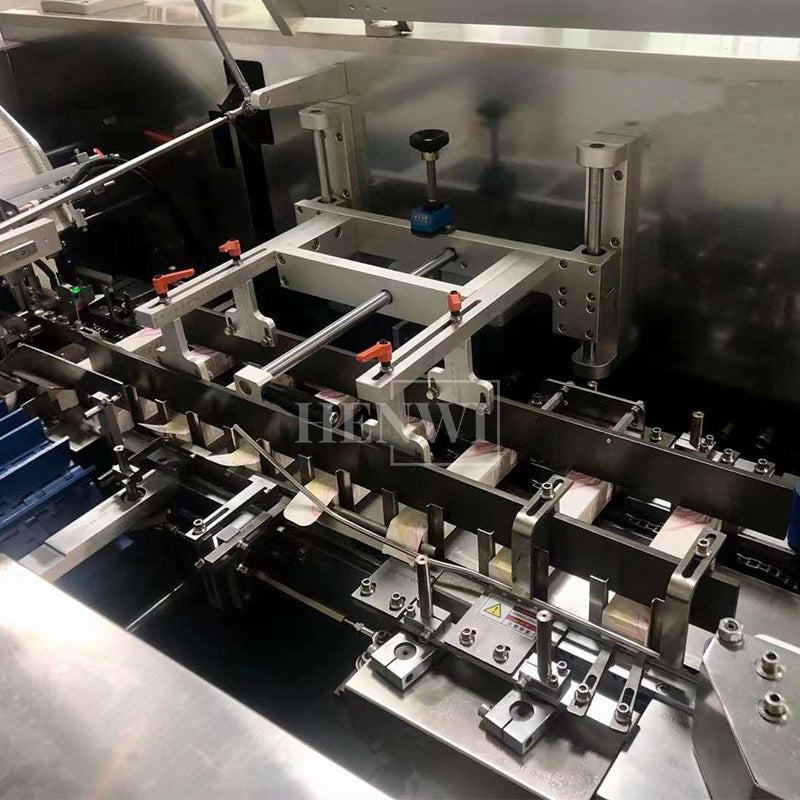

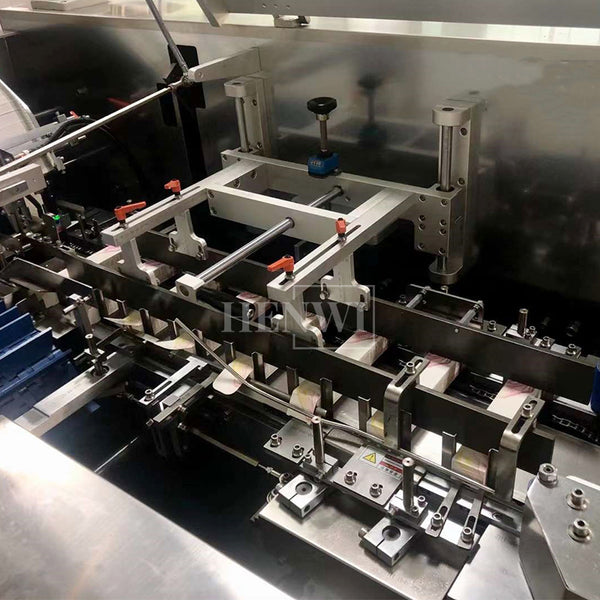

Automatic Horizontal Cartoning Machine

Overview: The Automatic Horizontal Cartoning Machine is a highly versatile, high-speed packaging system designed for packaging various items, including blister packs, bottles, tubes, soap, and other items in the pharmaceutical, food, cosmetic, and daily chemical industries. It employs a chain-driven, unidirectional transmission system for smooth, stable operation and a broad adjustment range, making it suitable for a wide range of products and packaging requirements.

Key Features:

-

Fully Automated Cartoning Process: This machine performs multiple packaging steps automatically, including leaflet folding, carton forming and opening, product insertion, batch printing, and carton sealing. It supports multiple sealing options, such as tuck-in or hot melt adhesive sealing with an optional hot glue system, providing flexibility for diverse packaging needs.

-

Advanced PLC Control with Error Detection: The machine is managed by a PLC (Programmable Logic Controller) system, with photoelectric sensors that monitor each part of the operation. If any issue arises, the machine will automatically stop and display the error on the control panel, allowing for quick troubleshooting and minimizing downtime.

-

Integrated Safety Features: Inside the machine frame, a main drive motor and a clutch brake ensure operational safety. Torque overload protectors are installed in the drive system to disengage the main motor from individual drive components under overload conditions, protecting the machine from damage and enhancing overall safety.

-

Intelligent Detection System: Equipped with a smart detection mechanism, the machine will not insert a leaflet or carton if no product is detected. It seamlessly integrates with upstream equipment to ensure smooth workflow. Defective items (such as those missing leaflets or products) are automatically rejected at the output, ensuring only fully compliant products reach the final packaging stage.

-

Standalone and Inline Flexibility: The machine can function as a standalone unit or work in conjunction with blister packaging machines and other equipment to form a fully automated production line, providing versatility for different production scales and needs.

-

Adaptability for Different Packaging Sizes and Formats: The machine allows for easy changeover between different packaging sizes, supporting small batch production with frequent changeovers. This adaptability makes it ideal for users who need to handle a wide range of product types with various carton sizes.

-

Diverse Feeding Solutions: Due to the wide variety of materials, the machine offers several feeding options to match different product shapes and sizes:

- Servo-Driven Blister Feeding Hopper: Ideal for storing and feeding blister packs or similarly shaped items with high storage capacity. Feeding time and quantity are controlled by a servo motor, adjustable via the touchscreen for convenient control.

- Bottle Buffer Platform: Designed for bottles, featuring a circular platform that organizes, stores, and queues bottle-shaped items, ensuring orderly entry into the cartoning machine.

- Granule and Patch Feeding Unit: For items with varying shapes and quantities, this unit uses conveyor sorting and robotic arms to handle feeding with automated control for counting, stacking, rejecting, and queuing.

- Custom Feeding Options: For special materials, custom feeding solutions can be designed to meet specific requirements.

Technical Specifications:

- Power Supply: AC 380V, 50Hz, three-phase, five-wire system

- Total Power: 1.5 kW

- Dimensions (L×W×H): 3300 × 1150 × 1900 mm

- Machine Weight: 1300 kg

- Production Capacity: 60-100 cartons/min

- Folding Speed for Leaflets: 60-100 leaflets/min

- Compressed Air Requirement: 2 cubic meters/hour at 0.5-0.7 MPa

-

Carton Specifications:

- Carton quality: 250-350 g/m² (dependent on carton size)

- Max Carton Size (L×W×H): 190 × 97 × 60 mm

- Min Carton Size (L×W×H): 58 × 25 × 15 mm

-

Leaflet Specifications:

- Paper quality: 60-70 g/m²

- Max Leaflet Size (L×W): 320 × 210 mm

- Min Leaflet Size (L×W): 100 × 100 mm

This cartoning machine offers a reliable, efficient, and flexible packaging solution that meets GMP standards for hygiene and safety, making it ideal for high-demand production environments. Its advanced features, intelligent controls, and comprehensive safety mechanisms ensure consistent quality and productivity.

Working process:

-

Feeding Device: The feeding device is designed to facilitate efficient loading of items into the packaging machine. It can be connected to upstream equipment for seamless integration with production lines, customized to fit different material requirements, or manually loaded by an operator, providing versatility to suit various production needs.

-

Box Opening Device: This device automatically opens folded flat boxes and prepares them for filling. With precise control, it ensures that each box is fully opened to the correct dimensions before entering the filling station, preventing jams and maintaining smooth workflow.

-

Box Loading Device: Once the box is opened, the loading device accurately places products inside. It is engineered to handle items gently and precisely, ensuring they are positioned correctly in the box. This process is adjustable to accommodate various product types and box sizes.

-

Box Side Flap Folding Device: This mechanism folds the small side flaps of the box after loading, ensuring a compact shape for sealing. Its precision helps maintain box integrity and makes the subsequent folding steps smoother, contributing to a secure final package.

-

Box Bottom Flap Folding Device: After the side flaps are folded, this device folds the bottom flap of the box, creating a stable base. It’s designed to prevent deformation and enhance the stability of the box, ensuring that products remain securely enclosed.

-

Box Top Flap Folding Device: This device folds down the top flap of the box, completing the closure process. By carefully securing the top flap, it keeps products sealed inside and prepares the box for sealing or gluing.

-

Glue Spraying Device: For boxes requiring a glued seal, this device accurately sprays adhesive onto the necessary flaps. It’s designed to apply glue precisely to ensure a strong seal while minimizing waste. The gluing system is adjustable and compatible with different types of adhesive, ensuring a reliable bond for various packaging needs.

-

Finished Product Output: After the boxes are sealed, the finished product output system moves them out of the machine and onto the next stage of production or packaging. This device ensures smooth and continuous flow, allowing for easy collection or transfer to subsequent processes.

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.