50L Semi-automatic Cosmetic cream & lotion production line

- Cena sprzedaży

- $23,610

- Cena regularna

- $25,000

- Oszczędzasz

- $1,390 (6%)

This 50L cosmetic cream production line is a complete set of production equipment system, designed for the manufacture of cream cosmetics (such as cream, lotion, cream, etc.). The production line ensures efficient, accurate and high-quality cosmetic cream production through the cooperation of various equipment, including reverse osmosis water treatment system, vacuum emulsification system, discharge pump, storage tank, filling machine, capping machine, labeling machine, tube packing machine, sachet packing machine and air compressor, etc.

Parameter

| Model: HWPL-CLS-50L |

| Capacity: 50 Liters/Batch |

| Time for per batch: 1-2hours (150-250Litres/Day) |

| Output: 1500-2500bottles/day (100ml) |

| Applicable bottle volume: 10-1000ml |

| Applicable package: bottle, soft tube, sachet |

| Number of workers needed: 5-7people |

| Total power: 40-60KW |

| Voltage: 220V & 380V (can be customized) |

Content

Configuration 1 |

| 250L/hour two- stage reverse osmosis water treatment * 1 set |

| 24W UV lamp * 1 set |

| 370W VDF water pump * 1 set |

| 500L SS304 water tank * 3 sets |

| 50L vacuum emulsifying mixer * 1 set |

| 1.5KW rotor pump * 1 set |

| 50L SS316 movable storage tank * 2 sets |

| Semi-automatic servo gear pump filling machine * 1 set |

| Semi-automatic capping machine * 1 set |

| Semi-automatic round bottle labeling machine with coding * 1 set |

| 5 meters transfer conveyor *1 set |

| 4KW air compressor set * 1 set |

Example application: bottle & cap ( red circle)

More information, please inquire!

Configuration 2 |

| 250L/hour two- stage reverse osmosis water treatment * 1 set |

| 24W UV lamp * 1 set |

| 370W VDF water pump * 1 set |

| 500L SS304 water tank * 3 sets |

| 50L vacuum emulsifying mixer * 1 set |

| 1.5KW rotor pump * 1 set |

| 50L SS316 movable storage tank * 2 sets |

| Semi-automatic servo gear pump filling machine * 1 set |

| Semi-automatic capping machine * 1 set |

| Semi-automatic round & square bottle labeling machine with coding * 1 set |

| 5 meters transfer conveyor *1 set |

| 4KW air compressor set * 1 set |

Example application: bottle & cap ( red circle)

More information, please inquire!

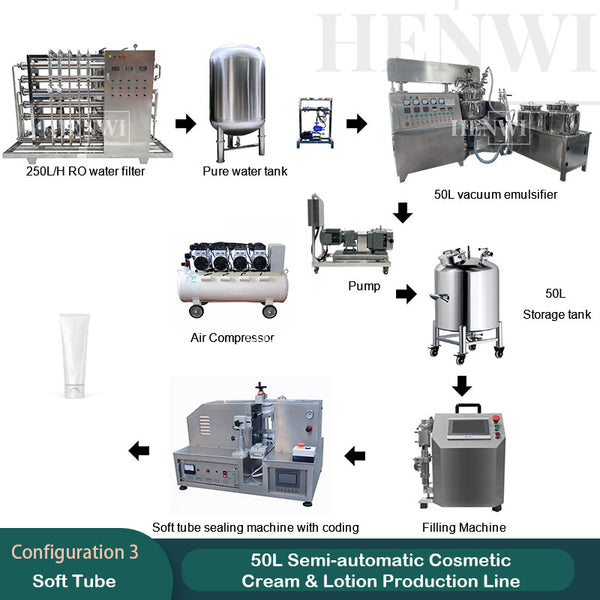

Configuration 3 |

| 250L/hour two- stage reverse osmosis water treatment * 1 set |

| 24W UV lamp * 1 set |

| 370W VDF water pump * 1 set |

| 500L SS304 water tank * 3 sets |

| 50L vacuum emulsifying mixer * 1 set |

| 1.5KW rotor pump * 1 set |

| 50L SS316 movable storage tank * 2 sets |

| Semi-automatic servo gear pump filling machine * 1 set |

| Semi-automatic soft tube sealing machine * 1 set |

| 4KW air compressor set * 1 set |

Example application: bottle & cap ( red circle)

More information, please inquire!

Configuration 4 |

| 250L/hour two- stage reverse osmosis water treatment * 1 set |

| 24W UV lamp * 1 set |

| 370W VDF water pump * 1 set |

| 500L SS304 water tank * 3 sets |

| 50L vacuum emulsifying mixer * 1 set |

| 1.5KW rotor pump * 1 set |

| 50L SS316 movable storage tank * 2 sets |

| Automatic liquid sachet filling and packing * 1 set |

| 4KW air compressor set * 1 set |

Example application: bottle & cap ( red circle)

More information, please inquire!

Configuration 5 |

| 250L/hour two- stage reverse osmosis water treatment * 1 set |

| 24W UV lamp * 1 set |

| 370W VDF water pump * 1 set |

| 500L SS304 water tank * 3 sets |

| 50L vacuum emulsifying mixer * 1 set |

| 1.5KW rotor pump * 1 set |

| 50L SS316 movable storage tank * 2 sets |

| Semi-automatic servo gear pump filling machine * 1 set |

| Semi-automatic capping machine * 1 set |

| Semi-automatic round & square bottle labeling machine with coding * 1 set |

| Semi-automatic soft tube sealing machine * 1 set |

| 5 meters transfer conveyor *1 set |

| 4KW air compressor set * 1 set |

Example application: bottle & cap ( red circle)

More information, please inquire!

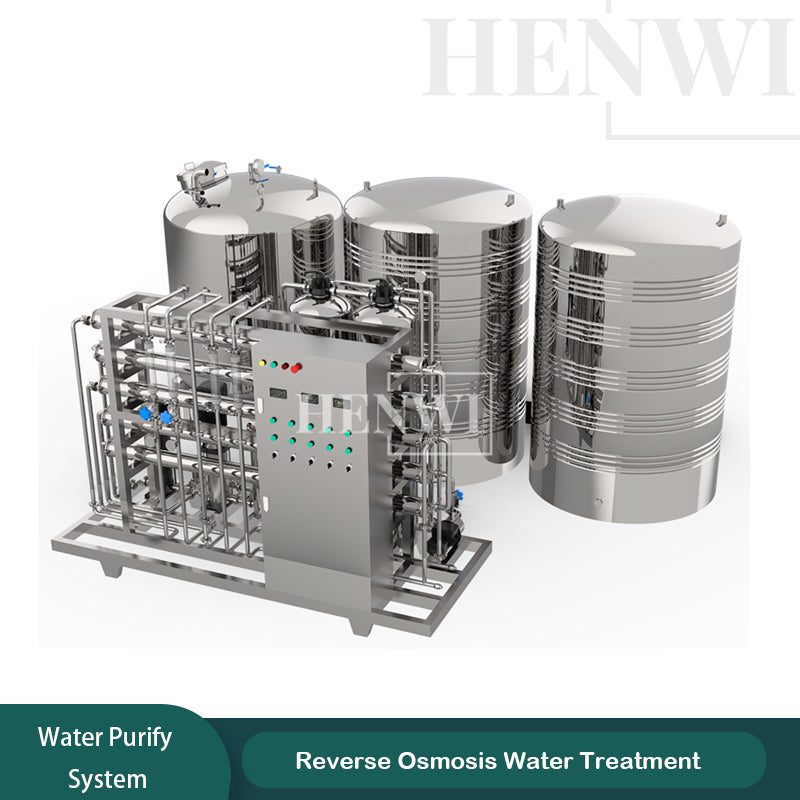

1. 250L/hour two- stage reverse osmosis water treatment

In the cosmetics production line, the reverse osmosis water treatment system (RO system) is one of the key links to ensure that the water quality meets the production requirements. Water is the most widely used raw material in cosmetics production, and its purity directly affects the quality and stability of the product. Reverse osmosis technology can effectively remove impurities, microorganisms, heavy metals and ions in water to ensure the purity of water.

| Item | Description |

|---|---|

| Capacity | 250L/h |

| Water Quality | Raw water conductivity ≤ 300 μs/cm One-stage: ≤8 μs/cm Two-stage: ≤2-3 μs/cm |

| Rejection Rate | ≥98% (Single membrane: 99.6%) |

| Recovery Rate | 60% |

| pH Range | 5.5 - 7.5 |

| Core Components | - Raw water pump - Sand filter (SUS304) - Carbon filter (SUS304) - Water softener - Precision filter - RO membrane |

| Power Requirements | High-pressure pumps: 0.75KW, two pumps, SUS304 construction |

| RO Membranes | 3 REBE4040 membranes |

| Control System | Automatic with PLC, conductivity sensors, pressure monitors, and solenoid valves |

| Support Structure | SUS304 |

| Electrical Control | Delixi components |

This system incorporates advanced monitoring and control features, ensuring efficient desalination and reliable water purity.

2. 500L SUS304 Water Storage Tank

This 500-liter water storage tank is constructed from durable SUS304 stainless steel, designed for optimal hygiene and durability in industrial and commercial applications. It includes a 300mm manhole for easy access, a spray ball for efficient cleaning, and a bottom discharge valve for streamlined drainage. The tank is mounted on a sturdy three-leg bracket that provides stability and can be securely fixed to the floor.

| Parameter | Specification |

|---|---|

| Tank Capacity | 500L |

| Material | SUS304 stainless steel |

| Shell Thickness | 2mm |

| Lid | 300mm manhole, product inlet, spray ball |

| Discharge | Bottom ball valve |

| Bracket | 3 legs with bracket, fixed on the floor |

3. VDF Pump & UV Sterilizer

This automatic variable frequency water pump, coupled with a UV sterilization light, is designed to provide efficient water flow management with added sterilization capabilities, ensuring high water quality for diverse applications. The pump operates with a powerful motor, adjustable speed, and reliable pressure control. The integrated UV light effectively eliminates bacteria and other microorganisms, maintaining purified water output.

| Parameter | Specification |

|---|---|

| Rated Lift | 20m |

| Rated Flow | 5m³/h |

| Power | 0.37KW |

| Sterilization UV Light Power | 40W (customizable) |

| Sterilization Effectiveness | Up to 99.9% bacterial removal |

| UV Lamp Lifespan | 8,000 hours |

| Material | SUS304 (pump housing) |

4. 50L vacuum emulsifying mixer

The 50L Hydraulic Lifting Vacuum Emulsifying Mixer is specifically designed for high-precision mixing of creams, lotions, and other viscous cosmetic products. It combines robust construction, high-shear mixing, vacuum capabilities, and reliable heating and cooling to ensure product consistency and purity. Below is a detailed breakdown of its features and technical specifications:

| Parameter | Details |

|---|---|

| Capacity | Design volume: 60L; Working volume: 50L |

| Lid | Equipped with a hydraulic lifting system for easy operation. Includes SUS316L lid (3mm thick), material filter, vacuum pressure gauge, CIP spray ball, and sight window. |

| Tank Structure | Triple-layer SUS316L construction for durability and temperature regulation: Inner layer (3mm), Middle layer (3mm), and Outer layer (2mm) with rock wool insulation for thermal efficiency. |

| Mixing System | Frame scraper mixing system: Power: 1.51KW, Speed: 0-65 rpm with Delta frequency inverter, Motor: Siemens, Blade Thickness: 10mm SUS316L with PTFE scraper for thorough blending |

| Bottom Homogenizer | Power: 2.2KW, Speed: 0-3200 rpm with Siemens motor and Delta frequency inverter. Rotor and stator use precision machining for enhanced homogenization; uses Burgmann mechanical seals and NSK bearings for durability |

| Heating & Cooling | Jacketed heating system with electric power (6KW) and tap water cooling; withstands standard pressure tests of ≤ 0.25 Mpa |

| Hydraulic Lift System | Equipped with a 0.55KW hydraulic lift system for smooth, precise lifting; product discharge by tilting the tank or via bottom ball valve (GMPSFI standard) for easy handling |

| Control System | Control cabinet featuring button operation, Delixi and Schneider electric components for durability and easy monitoring. Includes Delta MS300 frequency inverter |

| Vacuum Pump | 1.1KW water circulation vacuum pump for maintaining a stable vacuum, preventing oxidation and air bubbles in formulations |

| Water Tank | 45L capacity, SUS316L with rock wool insulation and electric heating (12KW); includes a discharge ball valve for controlled outflow. Includes high-shear mixer powered by a 0.55KW Siemens motor, designed for optimal dispersion |

| Oil Tank | 30L, SUS316L triple-layered construction; similar heating and insulation as the water tank. Includes high-shear mixer powered by a 0.55KW Siemens motor, designed for optimal dispersion |

| Additional Components | Includes Delixi breakers, ammeter, AC contactor, Schneider indicator lights, and a WINKPARK AK6 temperature display for comprehensive monitoring and control |

| Warranty & Service Life | 1-year warranty with an expected operational lifespan exceeding 10 years under standard use conditions |

This emulsifying mixer is engineered to facilitate rigorous cosmetic production standards, accommodating a wide range of viscosities with precision and efficiency. The mixer’s advanced features ensure high production quality, including airtight mixing, exact temperature regulation, and versatile control options, making it ideal for manufacturing creams, serums, lotions, and other cosmetic formulations.

5. 1.5KW rotor pump

The Rotary Pump is a robust, high-efficiency positive displacement pump ideal for handling a range of fluid viscosities in applications requiring controlled, high-precision flow. Below are its key technical specifications:

| Parameter | Description |

|---|---|

| Flow Rate | 0.6 tons per hour |

| Maximum Pressure | 0 - 0.6 Mpa |

| Speed | 10 - 800 rotations per minute (rpm) |

| Power | 1.5kW |

| Inlet/Outlet Diameter | DN 40/50 |

Key Features:

- Handles a wide speed range with adjustable output.

- Suitable for fluids with various viscosities.

- Durable construction for high-pressure applications.

These features make rotary pumps versatile, efficient, and capable of handling tasks from gentle fluid transfer to high-viscosity product processing.

6. 50L SS316 movable storage tank

The 50L Stainless Steel 316L Mobile Sealed Storage Tank is designed for hygienic and flexible storage applications, made from high-grade SUS316 stainless steel, suitable for a variety of liquid storage needs in clean environments. Here are the detailed specifications:

| Parameter | Details |

|---|---|

| Total Capacity | 60L |

| Working Capacity | 50L |

| Material | SUS316 Stainless Steel |

| Thickness | 1mm |

| Internal Finish | Sanitary polished to ≥300 mesh |

| Lid | 300mm man-hole with water inlet, spray ball, water level sensor inlet |

| Discharge | Bottom ball valve for efficient draining |

| Mobility | 4 universal wheels with legs for stability |

| Compliance | GMP hygiene standards |

Features:

- Sanitary Design: All contact surfaces meet high hygiene standards, ideal for industries like cosmetics and pharmaceuticals.

- Sealed Storage: Ensures secure containment of materials.

- Easy Mobility: Equipped with universal wheels for transportability.

This 500L tank is particularly suited for operations that require both clean storage and mobility.

7. Semi-automatic Servo Gear Pump Filling Machine (10-10000ml)

This semi-automatic servo gear pump filling machine is designed for high-precision liquid filling applications. It provides adjustable and accurate filling for a wide range of liquid volumes, making it ideal for industries such as cosmetics, pharmaceuticals, chemicals, and food production. The machine’s compact build, touch screen interface, and servo motor ensure ease of use and reliable, repeatable performance.

Key Features:

- Filling Volume Range: Accommodates a wide range of filling volumes from 10 ml to 10,000 ml, suitable for different production needs.

- High Precision Servo System: Equipped with a Hechuan (禾川) servo motor, offering accurate, consistent, and smooth filling operations.

- Touch Screen Control: The Delta (台达) touch screen control panel allows for intuitive setup, easy parameter adjustments, and operational monitoring.

- Compact Design: The compact structure with dimensions of 65 cm x 62 cm x 46 cm optimizes workspace usage and simplifies integration with existing production lines.

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions | 65 cm x 62 cm x 46 cm |

| Filling Volume Range | 10 – 10,000 ml |

| Control Interface | Delta Touch Screen |

| Servo Motor | Hechuan Servo Motor |

| Control Method | Semi-Automatic |

This machine combines accuracy, flexibility, and user-friendly controls, making it an excellent choice for small to medium-scale filling operations.

8. Semi-automatic Four-wheel Bottle Capping Machine

This semi-automatic four-wheel bottle capping machine is designed to efficiently cap bottles with screw caps using a system of four rubber wheels. It is ideal for a range of industries, including cosmetics, beverages, and pharmaceuticals, due to its high speed, precision, and reliable pneumatic components.

| Parameter | Specification |

|---|---|

| Capping Type | 4 rubber wheels |

| Applicable Cap Type | Screw cap |

| Cap Diameter | 20-80 mm |

| Capping Speed | 1200-2400 bottles/hour |

| Power | 0.5 KW |

| Voltage | 220V/50Hz |

| Working Air Pressure | 0.4-0.6 Mpa |

| Air Consumption | 1-3 m³/min |

| Control Panel | Button-operated |

| Machine Dimensions | 500 mm (L) x 380 mm (W) x 700 mm (H) |

| Machine Weight | 35 kg |

| Pneumatic Components | AirTac (Taiwan) |

Key Features

- High-Efficiency Four-Wheel Capping: The four rubber wheels ensure a firm grip on each cap, providing smooth and secure capping while maintaining bottle stability.

- Wide Cap Diameter Compatibility: Capable of handling cap diameters from 20mm to 80mm, accommodating various bottle sizes and cap styles.

- Adjustable Capping Speed: With a capping rate of 1200-2400 bottles per hour, this machine offers flexibility to meet production demands.

- Reliable Pneumatic System: Equipped with AirTac pneumatic components, known for their durability and performance, ensuring smooth and consistent operation.

- User-Friendly Control Panel: Simple button controls make it easy to operate, allowing quick adjustments for different capping requirements.

- Compact Design: Space-saving dimensions make it convenient for small production spaces, and the lightweight design allows for easy relocation within the production area.

This four-wheel capping machine provides an effective solution for medium to high production volumes, delivering efficient, consistent capping for screw-top bottles in a variety of industries. Its pneumatic design and sturdy build make it a durable choice for reliable performance over time.

9. Semi-automatic Round Bottle Labeling Machine with Coding

This semi-automatic round bottle labeling machine is designed for precise, efficient labeling of cylindrical bottles. It is widely used in industries such as food, cosmetics, pharmaceuticals, and beverages. Its user-friendly design allows for easy adjustments and operation, making it suitable for various bottle sizes and label types.

| Parameter | Specification |

|---|---|

| Labeling Type | Semi-automatic round bottle labeling |

| Bottle Type | Cylindrical bottles |

| Label Width Range | 10-150 mm |

| Label Length Range | 15-300 mm |

| Labeling Speed | 20-40 bottles/minute |

| Label Accuracy | ±1 mm |

| Bottle Diameter Range | 15-120 mm |

| Control Panel | Button-operated |

| Power | 0.2 KW |

| Voltage | 220V/50Hz |

| Machine Dimensions | 650 mm (L) x 450 mm (W) x 450 mm (H) |

| Machine Weight | 30 kg |

Features

- Accurate Label Placement: Achieves label accuracy of ±1 mm, ensuring precise positioning for a professional finish on each bottle.

- Adjustable Label Size Range: Supports labels with widths from 10 to 150 mm and lengths from 15 to 300 mm, allowing flexibility to accommodate various labeling requirements.

- Versatile Bottle Diameter Compatibility: Works with bottles with diameters between 15 and 120 mm, making it suitable for different bottle sizes used in diverse applications.

- Efficient Labeling Speed: Capable of labeling 20-40 bottles per minute, optimizing production efficiency for small to medium batch runs.

- Simple Control Panel: Operated with an easy-to-use button interface, making it straightforward to set up and adjust settings.

- Compact and Portable Design: The compact footprint and lightweight design enable convenient placement in production areas with limited space.

10. Semi-Automatic 360-Degree Rolling Labeling Machine

The Semi-Automatic 360-Degree Rolling Labeling Machine is designed to efficiently apply full-wrap labels on cylindrical items. Its robust build, featuring aluminum alloy and stainless steel components, enhances stability and precision.

Key features include:

- Labeling Accuracy: ±0.5 mm

- Speed: 15–30 items/min, depending on product size and user skill

- Label and Product Sizes: Compatible with labels up to 380mm length, 110mm width, and items with diameters from 20–250mm

- Electrical System: Equipped with a Panasonic FP PLC, SICK sensors, and a 3.5-inch touchscreen from Samkoon

This labeling system is ideal for industries requiring high-precision labeling with efficient and user-friendly operations.

| Component | Material | Electrical System | Quantity | Specifications |

|---|---|---|---|---|

| Unwinding Mechanism | Aluminum, Acrylic | Label Sensor | 1 | SICK Sensor, Germany |

| Label Pressing Mechanism | Aluminum, Manganese | PLC | 1 | Panasonic FP Series |

| Traction Mechanism | Aluminum, Rubber-Coated | Traction Motor | 1 | Leadshine Stepper Motor |

| Label Guiding Mechanism | Aluminum | Driver | 1 | Leadshine Stepper Driver |

| Label Peeling Mechanism | Stainless Steel | Label Covering Cylinder | 1 | CPC |

| Rewinding Mechanism | Stainless Steel, Acrylic | Power Supply | 1 | Mean Well |

| Control Box | Painted Metal | HMI | 1 | Samkoon 3.5-inch Touchscreen |

11. Semi-automatic soft tube sealing machine

The Ultrasonic Soft Tube Sealing Machine is designed for precise, efficient sealing of soft tubes across industries such as cosmetics, pharmaceuticals, food, and personal care. With advanced PLC control and robust ultrasonic technology, it provides high-quality seals for various tube materials, including plastic and composite. The machine’s compact and durable design allows for easy operation and consistent production performance.

-

Advanced Ultrasonic Sealing Technology

- Operates at 20 kHz for reliable sealing of different tube sizes and materials.

- Strong ultrasonic output ensures consistent sealing quality for plastic, composite, and multi-layered tubes.

- Includes automatic cutting function for clean and uniform tube edges.

-

User-Friendly PLC Control Interface

- Equipped with an advanced PLC control system for precise parameter setting, operational ease, and enhanced productivity.

- Independent human-machine interface with dual-direction adjustment simplifies the setup and operation.

-

High-Quality Construction and Durability

- Constructed from SUS304 stainless steel, offering excellent corrosion and acid-alkali resistance to meet hygiene standards for food, cosmetics, and pharmaceuticals.

- Includes aluminum alloy components and a durable design, providing long-lasting performance with low maintenance.

-

Safety and Reliability

- Features overload protection, phase difference protection, and power-fail protection to prevent damage and ensure safe operation.

- Air pressure requirements and built-in safeguards help maintain smooth and consistent operation.

Specifications

| Parameter | Specification |

|---|---|

| Control Type | Advanced PLC control |

| Frequency | 20 kHz |

| Power Supply | AC 110V/220V |

| Power | 1800 W |

| Sealing Diameter | φ5—φ50 mm |

| Max Tube Height | 10—250 mm |

| Production Capacity | Approx. 20-30 pcs/min |

| Air Pressure | 0.5—0.6 MPa |

| Dimensions (L×W×H) | 850 mm x 600 mm x 620 mm |

| Weight | 90 kg |

| Material | SUS304 stainless steel, aluminum alloy |

The Ultrasonic Soft Tube Sealing Machine is a versatile and reliable solution for high-quality sealing across various tube sizes and materials, combining advanced ultrasonic technology with an intuitive control system and durable construction for demanding production environments.

12. Automatic liquid sachet filling and packing machine

The Automatic Liquid Pouch Packaging Machine is a high-efficiency system designed for precise and rapid filling, sealing, and packaging of various liquid and semi-liquid products in flexible pouches. Its robust stainless steel construction, combined with advanced automation, makes it suitable for packaging liquids like cosmetics, sauces, and chemicals.

Technical Specifications:

| Parameter | Details |

|---|---|

| Voltage | AC 110V, 220V, or 380V |

| Power | 2.2 KW |

| Speed | 35-70 bags/min |

| Bag Type | Three-sided or four-sided sealed pouches |

| Bag Size | Length: 40-180mm, Width: 15-120mm |

| Packaging Materials | Paper, PE, PET, Nylon |

| Machine Dimensions | 650mm x 600mm x 1700mm |

| Weight | 180 Kg |

| Materials | SUS316L & SS304 Stainless Steel |

| Functions | Bag forming, weighing, filling, sealing, cutting, code printing |

| Applications | Suitable for liquid and paste-like substances such as shampoo, cream, sauces, jams, etc. |

Key Features:

- Automated Workflow: Fully automated processes for bag making, filling, and sealing.

- Versatile Applications: Can handle a range of liquid and semi-liquid products.

- Quality Materials: Uses food-grade stainless steel (SUS316L & SS304) for enhanced durability and hygiene.

This machine is ideal for medium to high-volume production requirements across industries, ensuring clean and consistent packaging with reduced manual intervention.

12. 4KW Air Compressor

This 4KW piston air compressor is engineered for high-performance air delivery in industrial and workshop environments. With a robust piston design, it delivers consistent air pressure while maintaining low noise levels, making it ideal for tasks requiring a reliable, quiet compressor.

| Parameter | Specification |

|---|---|

| Power | 4400 W |

| Working Principle | Piston compressor |

| Performance | Low noise |

| Speed | 1380 rpm |

| Cylinder Size | 69.7 x 22 x 8 mm |

| Maximum Pressure | 7.0 Bar |

| Air Capacity | 400 L/min |

| Tank Capacity | 160 L |

| Net Weight | 132 kg |

| Dimensions (L x W x H) | 134 x 47 x 81 cm |

Features

- High Efficiency: Delivers a consistent 400 L/min air output at a pressure of up to 7 Bar, suitable for demanding air supply needs.

- Piston Compressor Design: Equipped with a durable piston mechanism that provides reliable compression, making it ideal for heavy-duty use.

- Low Noise Operation: Designed to operate at reduced noise levels, enhancing the work environment.

- Robust Construction: The large 160L air tank and rugged design ensure durability and stability during extended use.

- Compact Yet Powerful: With a compact footprint, it saves space without compromising power, suitable for diverse workshop setups.

13. 5m Transfer Conveyor Belt

This PVC conveyor belt is designed for light industrial and assembly line applications, featuring excellent wear resistance and stability. The setup includes a reduction motor, frame, workbench, and high-quality green industrial belt with adjustable speed, suitable for a variety of conveying needs. Detailed specifications are as follows:

| Parameter | Specification |

|---|---|

| Total Length | 5 meters |

| Speed Control Motor | Taibang motor, power 0.4KW, variable frequency control, speed range 0-200 rpm |

| Frame Material | SUS304 Stainless Steel |

| Workbench Dimensions | Width: 750mm, Side Width: 250mm each; Height: 750mm (adjustable) |

| Workbench Thickness | 1.3mm |

| Belt Material | Green industrial PVC belt (Netherlands-made), thickness 2mm, belt width 250mm |

| Additional Features | Adjustable height, durable and easy to install |

Features

- Durable Design: Built with a stainless steel frame and high-quality PVC belt, ensuring robust construction suited for various environments.

- Adjustable Speed: Equipped with a variable frequency speed control motor to adapt the conveyor speed to your needs.

- Efficient and User-Friendly: Easy to install and maintain, this conveyor belt is ideal for continuous conveying operations, enhancing production efficiency.

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.