Semi-automatic vertical needle filling machine

- ราคา

- $1,790

The semi-automatic pneumatic syringe pressure piston filling machine is designed for precise filling of high-viscosity materials, equipped with a pressurizable hopper to ensure steady material flow. This machine is highly suitable for applications in the pharmaceutical, cosmetics, and food industries where precise, small-dose filling is essential, such as for syringes or similar narrow containers.

Key Features

Pressurized Hopper: The hopper can be pressurized, maintaining a continuous flow of dense, high-viscosity materials. This ensures even feeding into the piston chamber, preventing blockages and ensuring a smoother, consistent filling process, especially for thick or sticky substances.

Precise Syringe Filling: Utilizing a piston-driven system, this machine allows for highly accurate volume control, ideal for applications requiring exact dosing, such as in medical or lab settings. Accuracy is typically within ±1%, supporting strict quality standards.

Versatile Material Compatibility: The machine can handle a variety of high-viscosity materials, including gels, ointments, creams, and other thick liquids, making it ideal for filling syringes with dense formulations that require additional pressure to flow smoothly.

Pneumatic Operation: The machine operates using pneumatic control, making it energy-efficient and safe for flameproof or sterile environments. This also simplifies maintenance, as there are fewer electronic components to manage.

Hygienic, GMP-Compliant Design: Made with stainless steel parts that come into contact with the product, the machine adheres to GMP standards. Its design allows for easy disassembly, cleaning, and maintenance, essential for maintaining product hygiene in industries like pharmaceuticals and cosmetics.

Adjustable Filling Volume: Filling volume can be adjusted by modifying the piston stroke, allowing for flexibility in filling different syringe sizes or other small containers.

Application

Parameter

| Number of filling heads: 1 |

| Filling range: 1-20ml |

| Filling speed: 600-1800 bottles/hour |

| Measuring accuracy: ±0.1ml |

| Working air pressure: 0.6-0.7Mpa |

| Voltage: 220V, 0.1KW |

| Filling nozzle: Anti-drip |

| Hopper volume: 25L |

| Hopper pressure: 6Kg/CM2 |

| Machine size: 350*520*1450mm |

| Working table height:780mm |

| Machine weight: 50kgs |

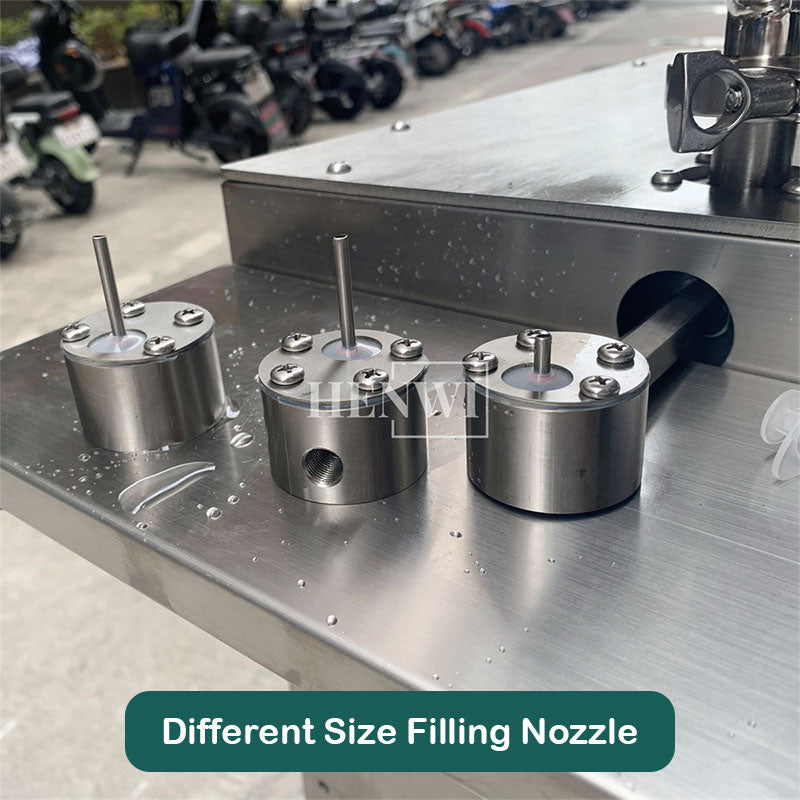

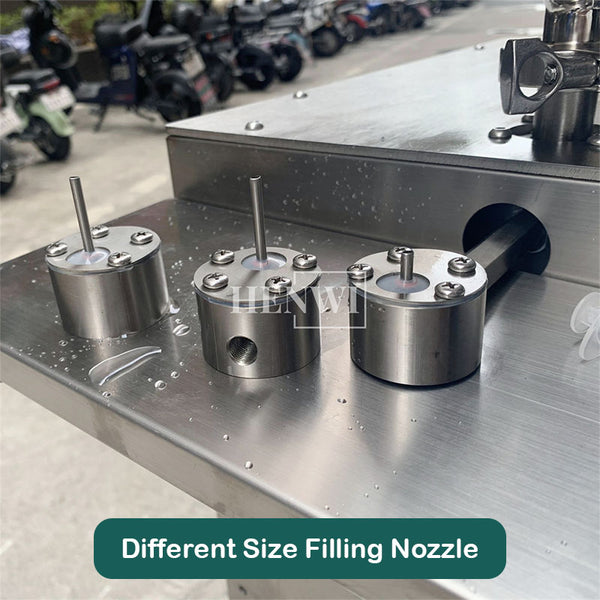

Filling Nozzle

The filling nozzle is specially designed for filling syringes to reduce the generation of bubbles and prevent the formation of bubbles during filling that affect product quality. It is suitable for filling high-viscosity materials.

Depending on the size and shape of the container, choosing the right filling nozzle can ensure that the liquid or paste can be filled into the container smoothly. For example, small bottles and large bottles may require different sized filling nozzles.

Filling System

The pneumatic system of the machine includes pneumatic piston pump, electromagnetic pneumatic valve, limiter, limit pneumatic valve and other components.

The pneumatic system of the machine includes pneumatic piston pump, electromagnetic pneumatic valve, limiter, limit pneumatic valve and other components.

Control Panel

The control panel has a power indicator light, manual/automatic button, production quantity counter, and pumping and injection speed adjustment buttons. It is convenient to control the machine.

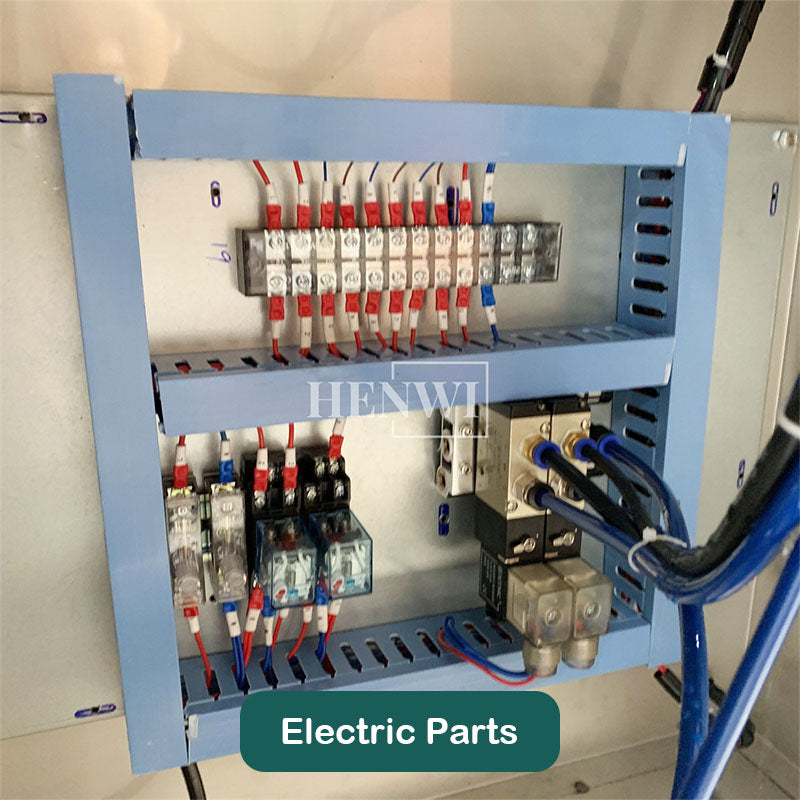

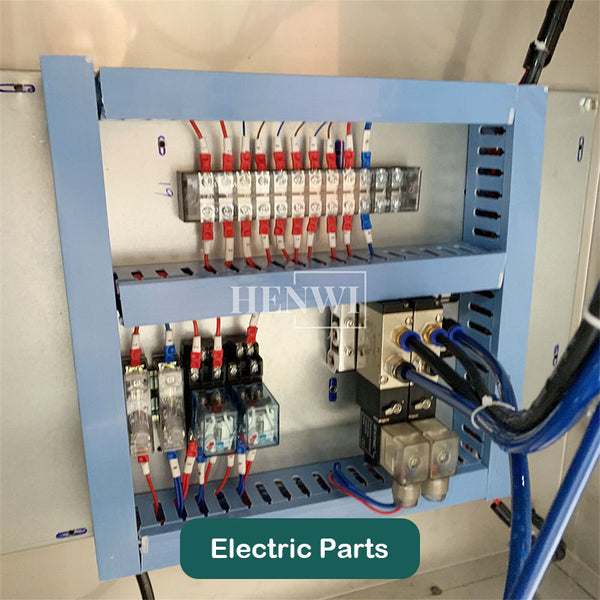

Electric Parts

The electronic components of the machine include electromagnetic pneumatic valves, wire connectors, relays, switches, power indicator lights, counters, etc.

The electronic components of the machine include electromagnetic pneumatic valves, wire connectors, relays, switches, power indicator lights, counters, etc.

Material Hopper

The air pressure gauge displays the air pressure level in the pneumatic system in real time, helping the operator monitor the working status of the system.

The hopper and hopper cover are effectively sealed by the flange to prevent the material from contacting the external environment (such as air and dust), thereby keeping the material clean. At the same time, the sealed environment is beneficial to pressurize the hopper, making the filling process smoother.

Filling Range Adjustment

In production, you may need to process containers of different sizes and specifications. The filling volume adjustment hand wheel provides flexibility, allowing the operator to quickly adjust the filling volume according to the container capacity and production needs to adapt to different production tasks.

In production, you may need to process containers of different sizes and specifications. The filling volume adjustment hand wheel provides flexibility, allowing the operator to quickly adjust the filling volume according to the container capacity and production needs to adapt to different production tasks.

Air Meter

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.