Manual Lipstick Production Line

- Pris

- $35,000

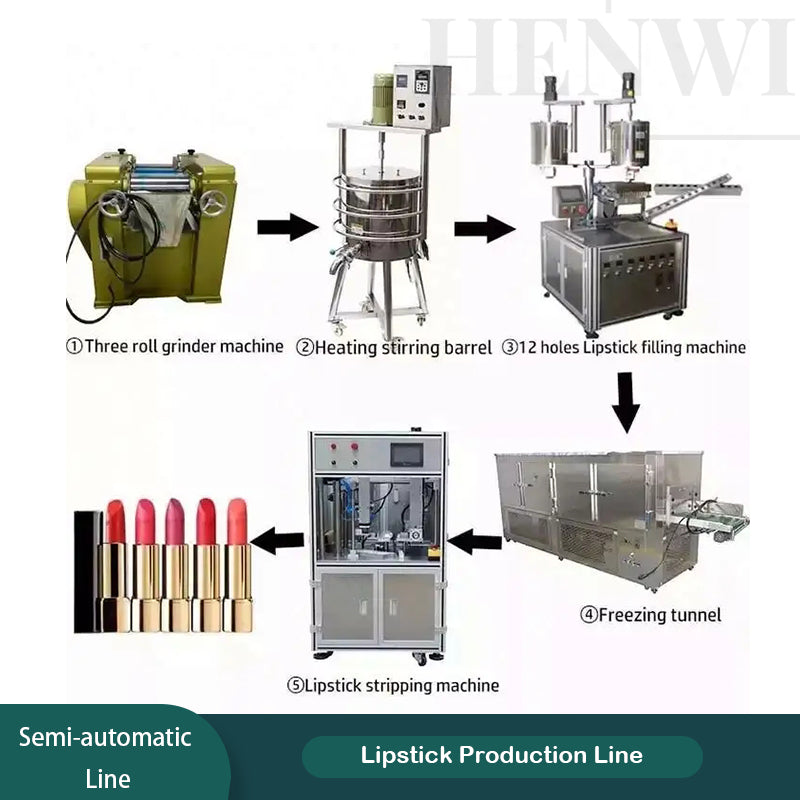

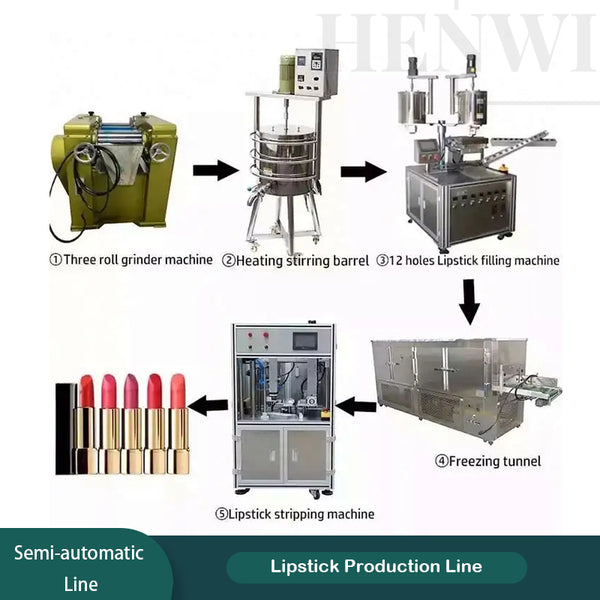

The semi-automatic lipstick production line consists of a variety of high-efficiency equipment, which work together to complete the entire process from raw material processing to finished product packaging. First, the three-roller grinder refines the pigments, waxes and oils to ensure fine particles and uniform color. Then, the raw materials are sent to the heated mixing tank, and through precise temperature control and high-speed stirring, all ingredients are fully mixed and kept in liquid state. The automatic 12-head filling machine can accurately fill the liquid lipstick material into multiple customized lipstick molds at the same time to ensure the consistent dosage of each lipstick. Subsequently, the filled molds enter the 5-meter-long single-row freezing tunnel for rapid cooling and solidification. After cooling, the automatic lipstick demoulding machine uses a pneumatic device to easily remove the solidified lipstick from the mold to ensure that the product appearance is intact. The entire production line relies on a 7.5KW air compressor to provide stable air pressure to ensure the continuous operation of pneumatic equipment such as demoulding and filling. Through the close cooperation of these automated equipment, the production line achieves efficient and accurate lipstick production, ensuring product quality and production efficiency.

Parameter

| Model: HWLP-S |

| Capacity: 15000-20000tubes/day |

| Applicable lipstick tube volume: 1-11ml |

| Applicable lipstick tube: Customized |

| Number of workers needed: 5-7people |

| Total power: 25KW |

| Voltage: 220V & 380V (can be customized) |

Content

| S150 Three-roll mill * 1 set |

| 70L heating mixing tank * 1 set |

| 12-hole lipstick filling machine * 1 set |

| 3M freezing tunnel * 1 set |

| Lipstick stripping machine * 1 set |

| Mold preheating machine * 1 set |

| Lipstick tube capping machine * 1 set |

| Lipstick mold * 6 sets |

| 7.5KW air compressor set * 1 set |

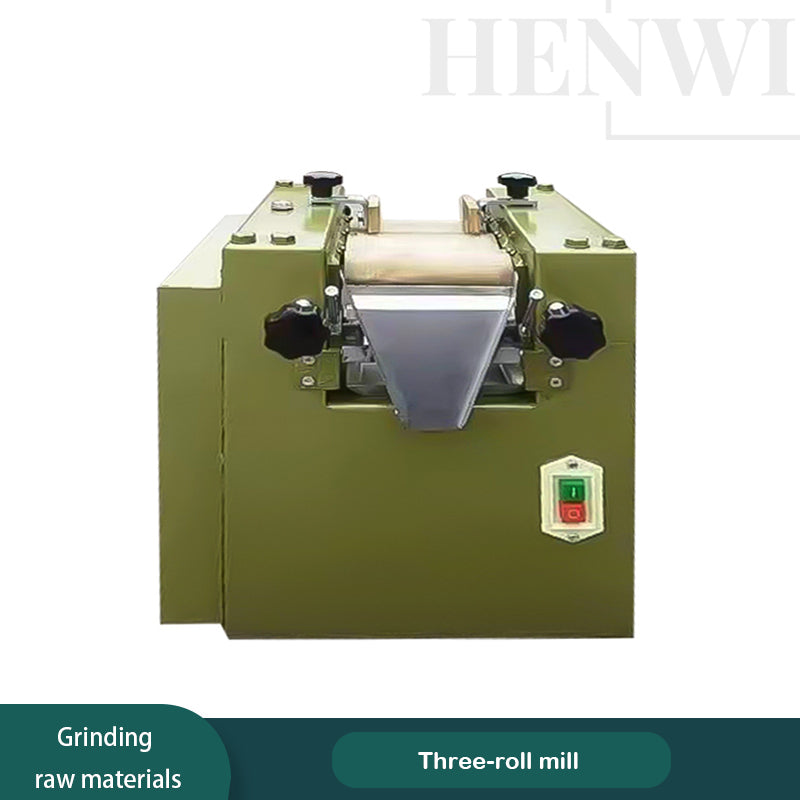

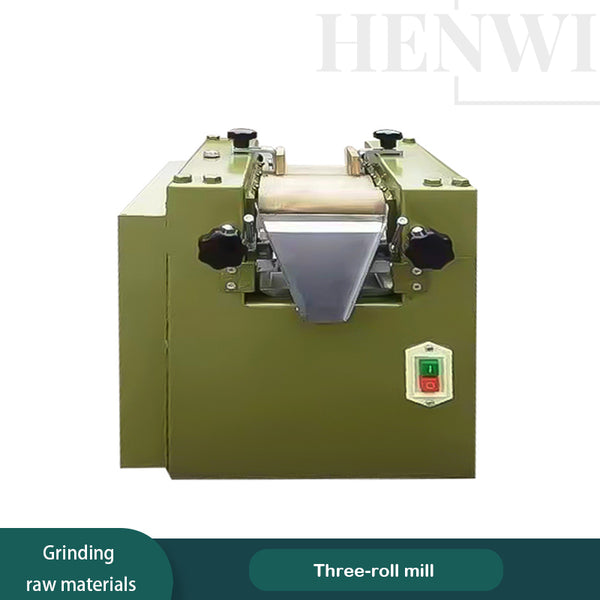

S150 Three-roll Mill |

| In the process of automated lipstick production, the three-roller grinder is a key equipment, mainly used to mix and refine the pigments, waxes and oil components in lipstick. The three-roller grinder shears and grinds the material through three rollers that are parallel to each other and rotate in different directions to obtain a uniform and delicate paste, thereby ensuring that the color and texture of the lipstick achieve the desired effect. ### Working principle of the three-roller grinder: 1. **Feeding**: The initial mixture of lipstick (including pigments, oils and waxes) is fed into the gap between the three rollers. 2. **Shearing and grinding**: The material is subjected to strong shear force between the two rollers, and is constantly squeezed and stretched. The speed difference caused by the different rotation speed of each roller causes the material to be gradually broken up and refined when passing through the rollers. 3. **Output**: After passing through the third roller, the material has been ground into an extremely fine paste, and then collected for the next step, such as degassing, molding, etc. ### Equipment features: - **Fine control**: The three-roller grinder can adjust the gap between the rollers to control the grinding accuracy, usually reaching micron-level fineness. - **Strong stability**: Since the rollers are usually made of high-strength alloys or ceramics, the stability and wear resistance of the equipment can be maintained for a long time. - **Efficient mixing**: Through multiple cycles of grinding, the pigments in the material can be fully mixed with the matrix to ensure color uniformity and brightness. ### Importance in lipstick production: 1. **Uniform color**: The three-roller grinder can make the pigments more evenly dispersed, ensuring that the color of the lipstick is consistent and free of graininess. 2. **Improved texture**: The grinding process can make the lipstick paste more delicate and smooth, improving the texture when used. 3. **Enhanced stability**: The material after three-roller grinding has better stability and is not easy to stratify or produce particle precipitation. |

70L Heating Mixing Tank |

| In the automated lipstick production, the heating and stirring tank is another key equipment, which is mainly used to evenly mix and heat various ingredients (such as oils, waxes, pigments, etc.) so that they can be fully integrated at a suitable temperature to form a uniform liquid paste. This equipment ensures the uniformity of ingredient mixing and the fluidity of the materials, laying the foundation for the subsequent filling process. ### Working principle of the heating and stirring tank: 1. **Heating function**: The tank body is usually equipped with an external or internal heating device (such as an electric heating or steam heating system) to accurately control the temperature to ensure that ingredients such as wax and oil can be completely melted and evenly mixed. 2. **Stirring function**: The stirring paddle or stirring shaft in the tank continuously shears, stirs and flips the material through rotational motion, thereby preventing stratification or precipitation and promoting uniform mixing. 3. **Temperature control**: The heating and stirring tank is usually equipped with a precise temperature control system that can monitor and adjust the temperature in the tank in real time to avoid deterioration of ingredients due to overheating, or incomplete fusion of materials due to low temperature. ### Equipment features: - **Uniform mixing**: Through strong stirring, different materials (such as solid wax and liquid grease) are evenly blended to ensure the stability of the final paste. - **Precise temperature control**: Different heating temperatures can be set according to the needs of different formulas to ensure the ideal melting point and mixing effect of various ingredients. |

Mold Preheating Machine |

|

In the lipstick production process, the **lipstick mold preheater** is a device used to heat the mold to the appropriate temperature, usually before the filling process. Preheating the mold helps ensure that the liquid lipstick paste can flow smoothly into the mold during filling, and prevents bubbles, cracks or other defects on the paste surface due to overcooling of the mold, thereby improving product quality. ### Working principle of lipstick mold preheater: |

12-hole Lipstick Filling Machine |

|

In the lipstick production, the automatic 12-hole lipstick filling machine is a device specifically used to accurately inject liquid lipstick materials into lipstick molds. The machine has a multi-hole filling function and is usually designed with 12 filling holes, which can fill 12 lipstick pastes at the same time, greatly improving production efficiency. ### Working principle of the automatic 12-hole lipstick filling machine: |

3M Freezing Tunnel |

|

In lipstick production, the **5PH freezing tunnel** is a device used to quickly cool and solidify lipstick paste, usually located after the filling process. The lipstick paste needs to be quickly cooled after filling into the mold to ensure that it solidifies and forms. The freezing tunnel quickly reduces the temperature of the lipstick through a low-temperature environment, so that the paste changes from a liquid or semi-liquid state to a solid state, achieving the desired hardness and shape. ### Working principle of the 5PH freezing tunnel: |

Lipstick Stripping Machine |

|

In the lipstick production, the **automatic lipstick demoulding machine** is a device specifically used to remove the cooled and fixed lipstick from the mold. This step usually follows the freezing tunnel. The automated operation of the demoulding machine not only improves production efficiency, but also ensures the integrity of the lipstick during the demoulding process, avoiding damage or defects caused by human operation. ### Working principle of the automatic lipstick demoulding machine: |

Lipstick Tube Capping Machine |

|

In the lipstick production process, the **lipstick tube automatic capping machine** is a device used to automatically cap the lipstick that has been shelled. It is usually located after the shelling process, and can efficiently and accurately tighten the cap of the lipstick tube into place, ensuring that each lipstick is in a sealed state before packaging is completed. This equipment greatly improves production efficiency and ensures product consistency and packaging quality. ### Working principle of the lipstick tube automatic capping machine: |

7.5KW Air Compressor Set |

|

In the lipstick production process, **air compressor** is a device that provides compressed air, which is often used to drive pneumatic equipment and process operations on the production line. Compressed air is used as a power source to drive the mechanical devices of filling, demoulding, capping and other equipment to improve production efficiency and automation. The stable operation of the air compressor is crucial to the continuity and accuracy of the entire production line. ### Working principle of air compressor: |

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.