Automatic Film sleeve packing and shrinking machine

- Price

- $9,500

The Automatic Sleeve Labeling Machine is designed for efficient and precise labeling of products using high-performance components and flexible configuration options. It integrates advanced PLC programmable logic control from Panasonic for precise operation and features a servo-driven traction motor system by LEADSHINE, ensuring reliable and consistent labeling speed. With label sensors from LEUZE or SICK and a user-friendly human-machine interface from SAMKOOM, this machine offers seamless control and monitoring of the labeling process. The labeling accuracy is maintained at ±1mm, allowing for high precision even with variable product dimensions.

Features and Components

- Label Dispensing Mechanism: Constructed from durable stainless steel and aluminum alloy, this unit supports consistent and efficient label release, enhancing the operational life of the machine.

- Feeding and Cutting Mechanism: Equipped with diamond and aluminum alloy components, alongside specialized rubberized parts, this mechanism ensures a smooth and accurate label feed, accommodating a wide range of label sizes (20-200mm in length) and supplies up to an external diameter of 500mm.

- Conveyor System: The stainless steel and aluminum alloy conveyor efficiently transports products through the machine, coordinating with the labeling system to achieve speeds of up to 120 pieces per minute, depending on product and label dimensions.

- Bottle Separating and Guiding Mechanism: Designed with stainless steel and aluminum components, this system maintains precise product spacing and orientation, critical for accurate label application.

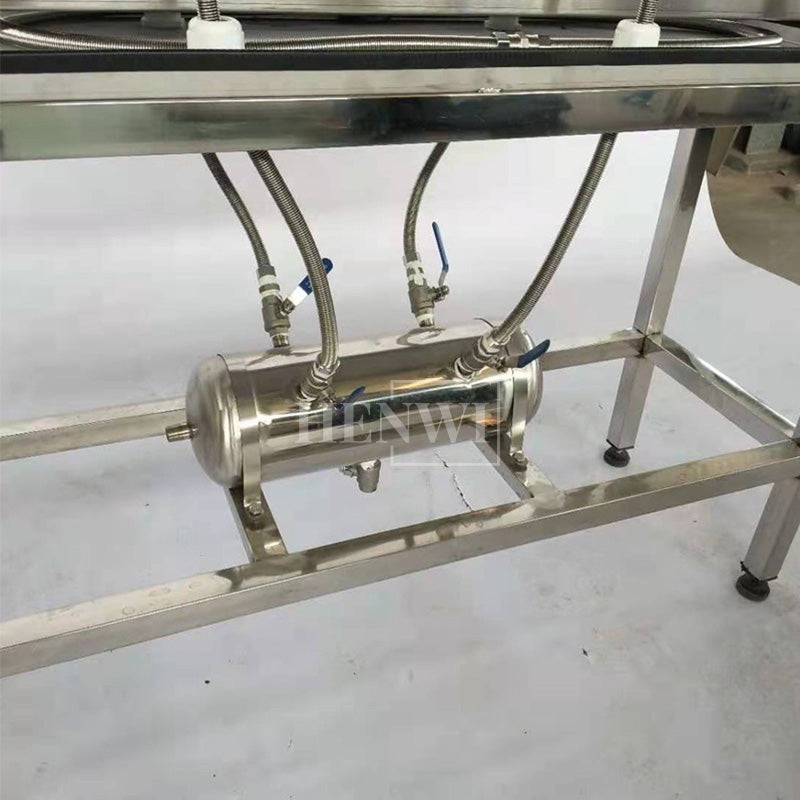

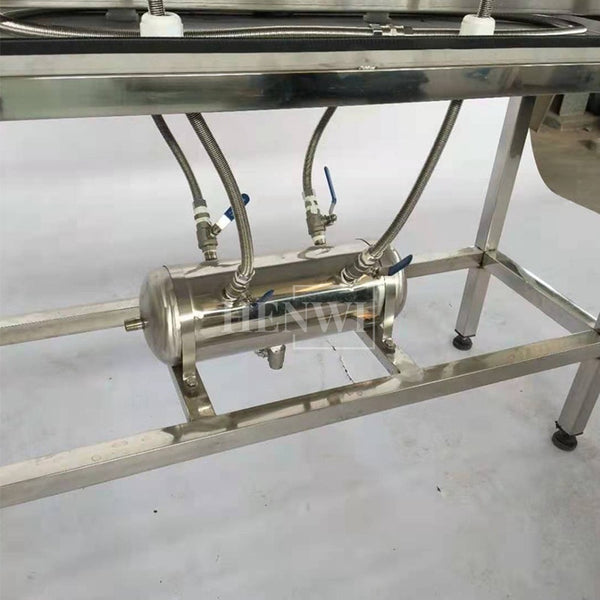

- Shrink Tunnel: Built with stainless steel and equipped with a high-efficiency steam heating unit, the shrink tunnel securely conforms the sleeve label around the product surface, creating a professionally wrapped appearance.

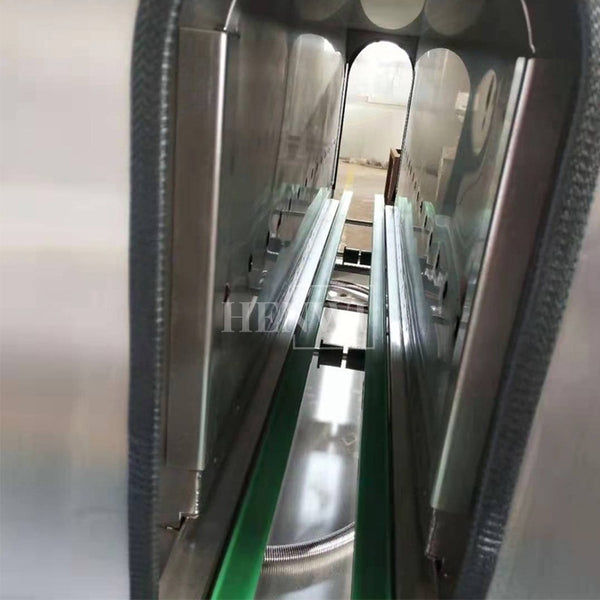

- Center Guiding Post: Made of stainless steel and POM, the central guide post stabilizes products as they pass through the labeling station, ensuring accurate label alignment.

Technical Specifications

- Labeling Speed: Approx. 0-120 pieces per minute, dependent on product size and label dimensions

- Labeling Precision: ±1mm (excluding product or label errors)

- Product Size Range: Diameter 20-100mm, Height 30-260mm

- Label Range: Length 20-200mm

- Label Supply Size: Max. outer diameter of 500mm, inner diameter of 76mm

- Operating Temperature/Humidity: 0-50°C, 15-85%

- Power Specifications: AC220/380V, 50Hz

- Machine Dimensions & Weight: Approx. 5000mm (L) x 1050mm (W) x 2000mm (H) / ~300Kg

This machine provides a customizable setup, adaptable to specific client needs and production requirements, with adjustments made for optimal efficiency within the same class of configurations.

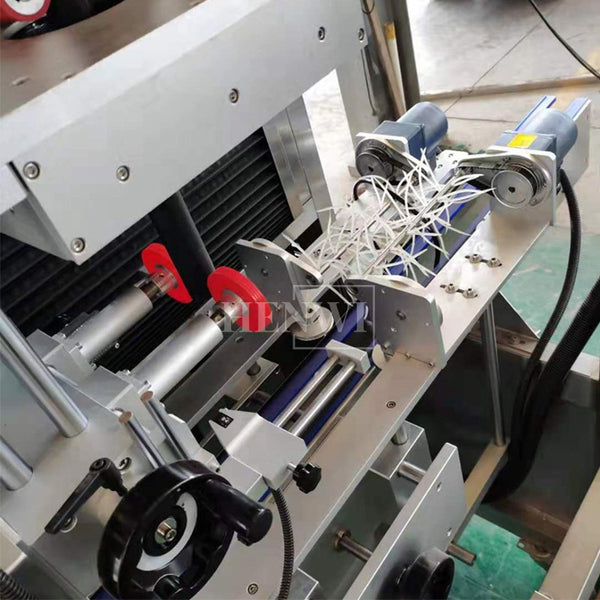

Knife Disc Assembly

The knife disc assembly includes a set of blades configured in a planetary arrangement with an offset crankshaft structure, designed to precisely cut the shrink film as it moves along the labeling path.

Machine Frame

The main frame of the machine is constructed from anodized aluminum and 304 stainless steel, providing stable support for the machine and securely anchoring the conveyor belt system.

Shrink Tunnel (Electric or Steam)

Utilizing either electric heating or steam, the shrink tunnel evenly applies heat to the labels on the bottles, ensuring the labels tightly adhere and conform to the contours of each bottle.

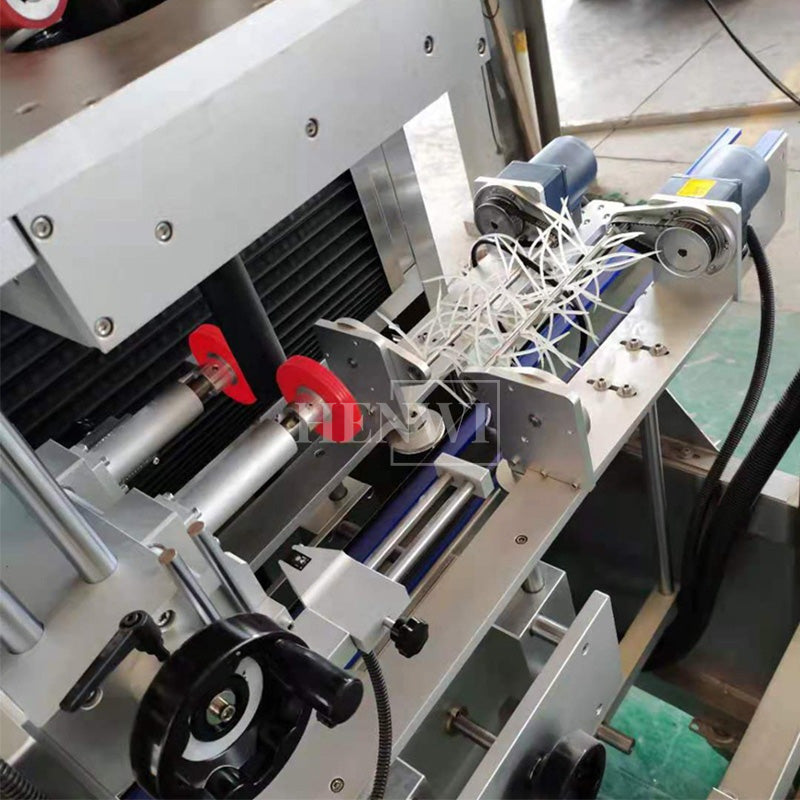

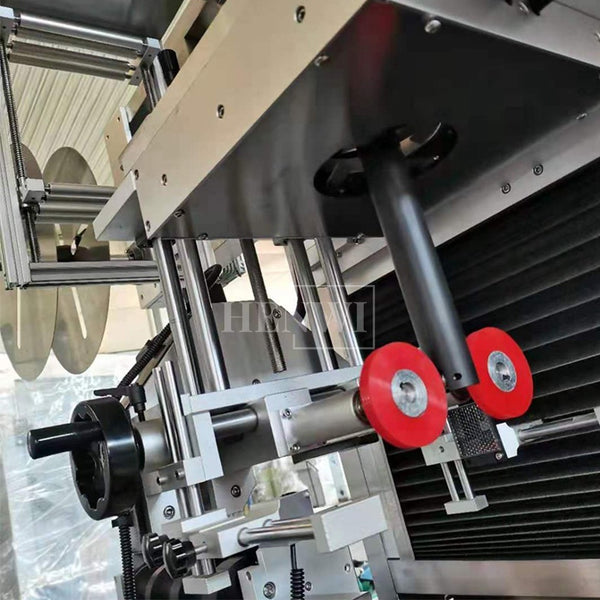

Drive Unit

Equipped with one or two servo motor systems that synchronize perfectly to ensure the shrink film is fed at a consistent, fixed length, maintaining the accuracy of each label cut.

Bottle Separation Screw

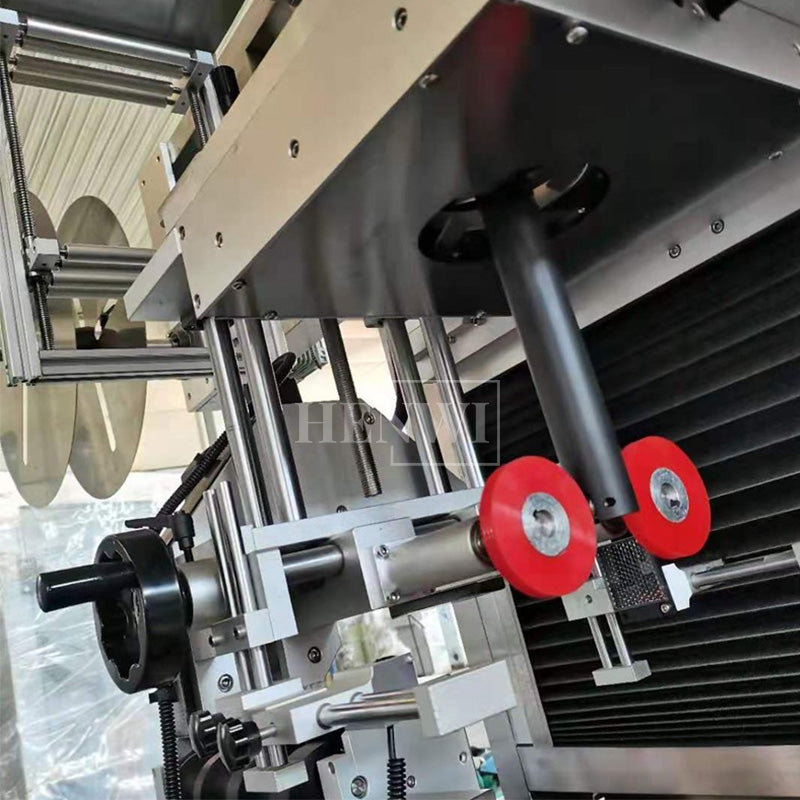

The separation screw controls the spacing of bottles on the conveyor belt, ensuring that each bottle is positioned at a precise interval to allow accurate label application.

Bottle Holding Assembly

Positioned on either side of the conveyor, this assembly stabilizes the bottles as they move, preventing wobbling during transport. It features a single handwheel for easy height and clamp positioning adjustments, facilitating precise label height alignment.

Three-Color Warning Light

A three-color indicator light system displays machine status: green for normal operation, yellow flashing when film material is low, and red flashing to signal any operational issues.

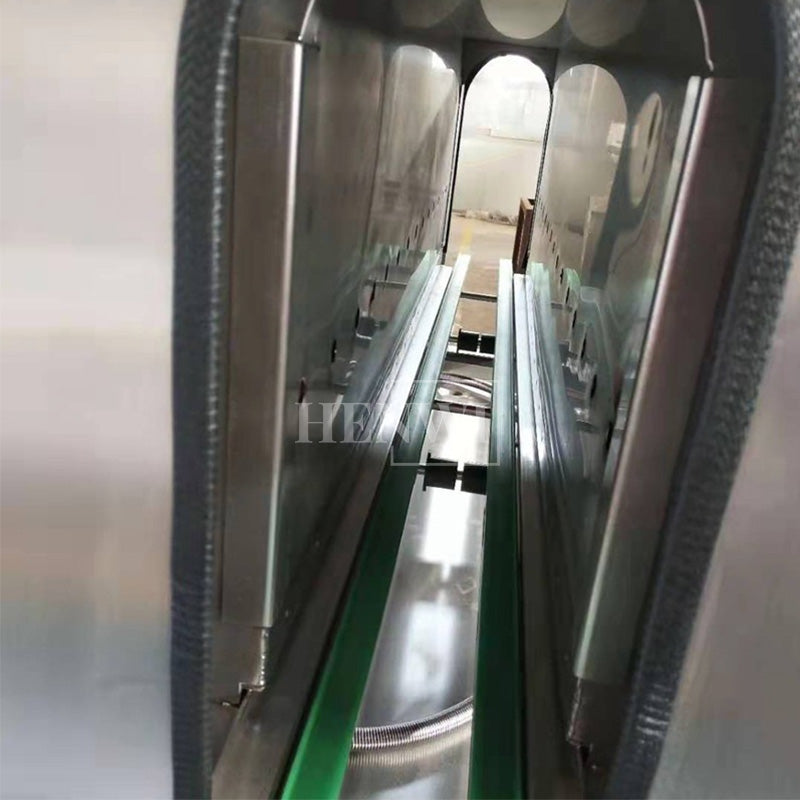

Centering Column

This component expands the label film, keeping it in position for precise transmission and cutting, allowing each label to be applied seamlessly around each bottle.

Photocell Mount Assembly

Equipped with a photocell sensor, this mount detects label position by emitting signals to the control system, allowing exact positioning adjustments to ensure labels are cut at the correct length.

Brush Assembly

With rubber bristles, the brush assembly ensures each applied label is firmly pressed into position on the bottle surface, enhancing the quality of label adherence.

Label Brush Down Assembly

Using a synchronized adjustment mechanism, this assembly aligns two brushing wheels beneath the centering column to lightly contact the rollers, smoothly pushing each label onto the bottle.

Material Rack Assembly

The material rack holds the label film roll with adjustable paper rings from 5” to 10”, feeding the film through a set of roller conveyors driven by a reduction motor for controlled film output.

Conveyor Belt

Driven by a variable frequency drive, the conveyor belt’s speed can be adjusted to match production capacity, ensuring synchronized movement with the rest of the labeling process.

Bottle Detection Sensor

Positioned to monitor bottle location on the conveyor, this sensor triggers the label application when a bottle reaches the correct labeling point.

Label Feed Assembly

Consisting of a feed box to control label tension and a top-mounted feed frame for label direction positioning, this assembly maintains smooth, controlled film transport to the cutting station.

Human-Machine Interface (HMI)

Serving as the control center of the machine, the HMI organizes operational functions into manual, automatic, setup, and error display modes, with additional control buttons and knobs for label application adjustments.

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.