Automatic Film overwrapping and sealing machine

- Price

- $11,800

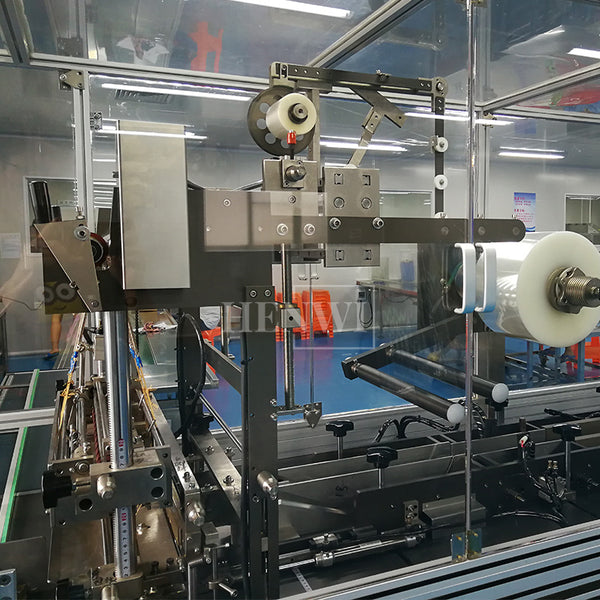

Automatic Film Overwrapping and Sealing Machine

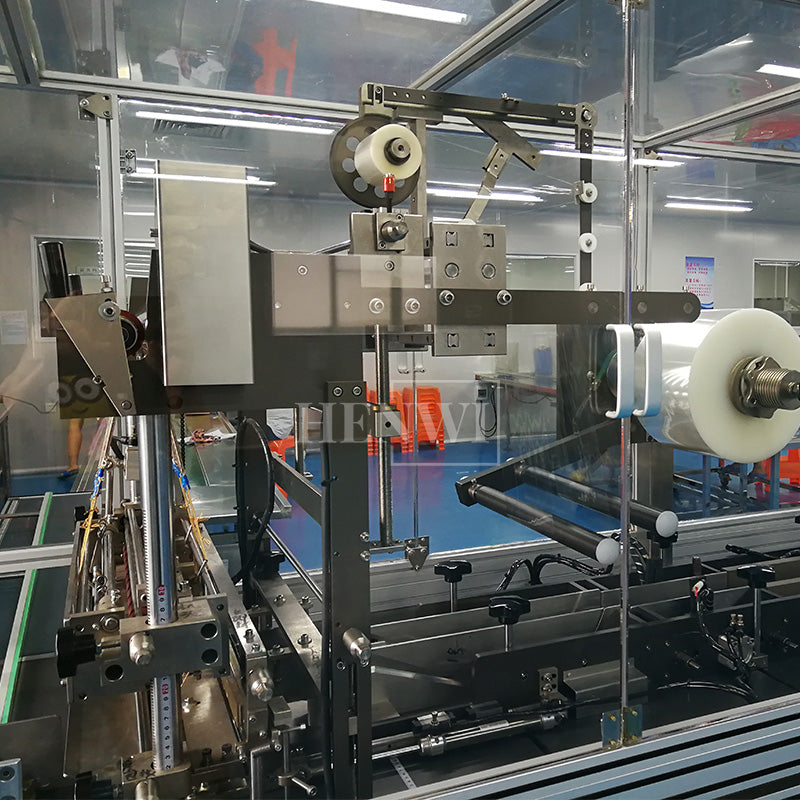

The Automatic Film Overwrapping and Sealing Machine is engineered for efficient and high-quality wrapping of various boxed products in industries such as cosmetics, pharmaceuticals, food, and electronics. It features a streamlined, linear feeding design and is capable of handling single items or bundled packages of various sizes. The machine uses PLC with a human-machine interface for ease of control, and main drives powered by dual servo motors ensure speed, stability, and precision.

Applications and Key Features:

-

Versatile Packaging for Different Box Sizes: Suitable for small, medium, and large boxed items, this machine accommodates single products or bundled items through a linear feeding system. Its stainless steel platform and components ensure hygienic operation, meeting industry standards. Quick part adjustments make it adaptable to different box specifications without the need for extensive reconfiguration.

-

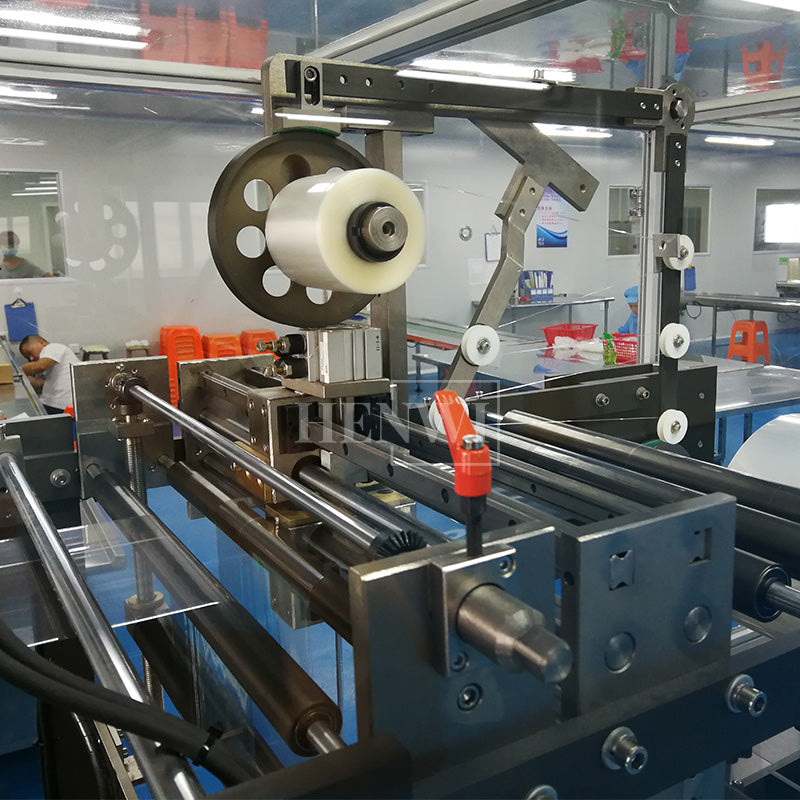

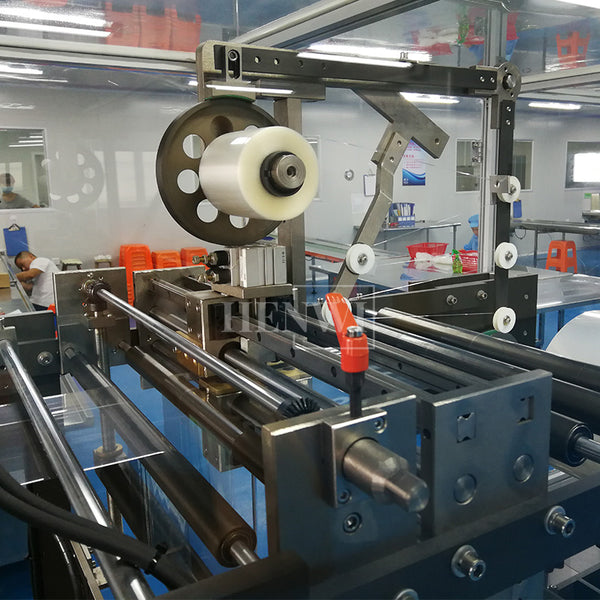

Dual Servo-Driven System: The dual-servo design provides fast, stable operation, making it ideal for high-volume, multi-specification packaging needs. The system also includes servo-driven film handling, allowing operators to adjust film size as required for different product dimensions, enhancing efficiency and precision.

-

Optional Add-Ons for Flexibility: The machine can be equipped with additional features, such as an easy-tear line mechanism, automatic box-flipping module, box coding, and even a six-side hot stamping function. These options make it adaptable for varied production requirements, adding flexibility and value.

Enhanced Machine Advantages:

-

Fixed Mold Design: The machine’s fixed mold design allows for quick and easy mold changes, saving time when switching between products.

-

Simple Mold Adjustment: Adjustments between products are significantly faster and simpler compared to traditional systems, minimizing downtime.

-

Efficient Film Handling System: The improved film handling system ensures smooth, stable film feed, reducing jamming and ensuring consistent wrapping quality.

-

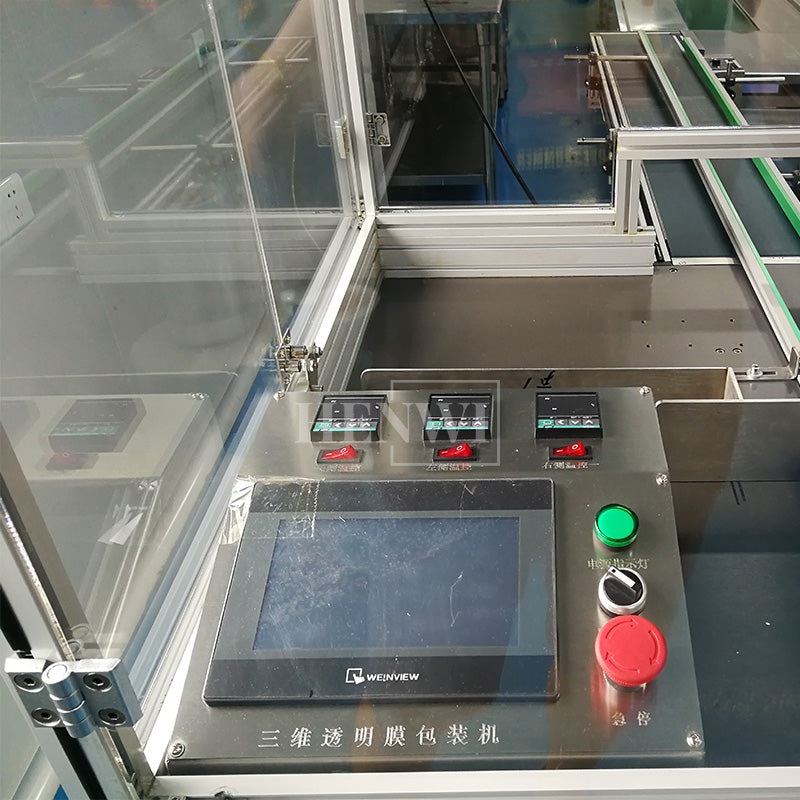

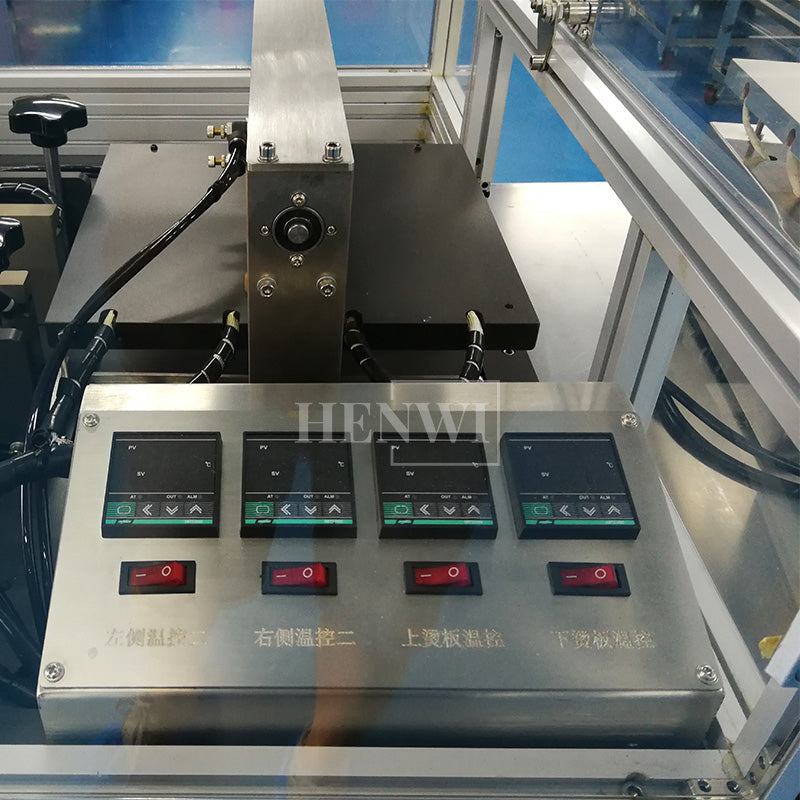

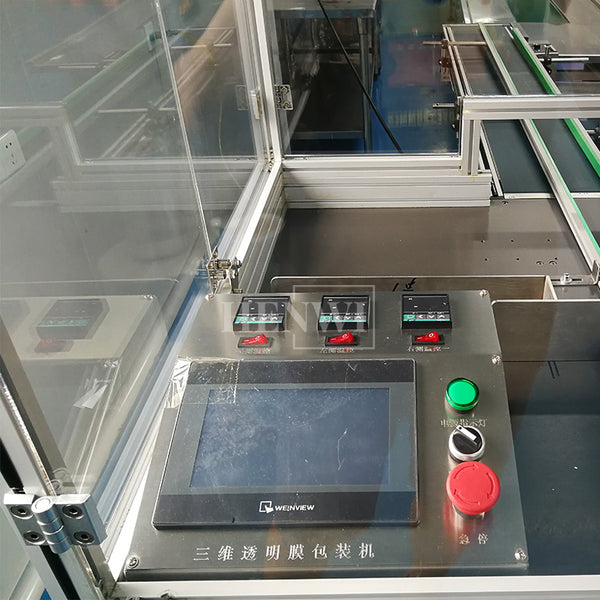

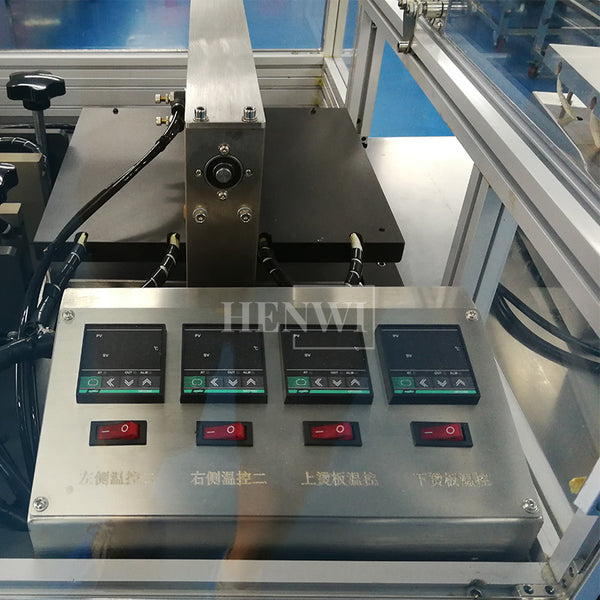

Integrated Temperature Control: The temperature control has been upgraded to a PLC modular system, enabling easier and more precise touch-screen operation, enhancing control over the sealing process.

-

Electronic Safety Protections: An electronic protection system with pusher and film-folding actions incorporates alarm functions for box jamming or product misalignment, automatically stopping the machine to ensure operational safety.

-

Linear Feeding Design: The linear feeding mechanism allows seamless integration with other equipment on the production line. The synchronized conveyor belt can operate in either intermittent or continuous mode, and features a protective design to prevent product scratching, maintaining a high-quality finish.

Technical Specifications:

- Model: 560 5G

- Power Supply: AC 380V, 50Hz

- Total Power: 6.5 kW

- Energy Consumption: 0.25 kW

- Working Pressure: 0.5-0.7 MPa

- Air Volume: 0.95 m³/min

- Packaging Size (mm): Length (L) 50-260, Width (W) 40-250, Height (H) 20-85

- Film Material: Heat-sealable glassine, OPP (BOPP) film, or double-sided PVC film, thickness 0.021-0.03 mm

- Core Diameter: 76 mm, Film Width: 1.2-3 mm

- Packaging Speed: 45-60 boxes per minute

- Max Film Width: 380 mm

- Dimensions (L×W×H): 2350×900×1650 mm (without six-side hot stamping)

- Conveyor Platform Size (L×W×H): 1650×350×950 mm

- Weight: 800 kg

Components List:

| Component | Brand |

|---|---|

| PLC | Panasonic, Japan |

| Signal Output Module | |

| Servo Driver | V&T, Shenzhen |

| AC Contactor | Chint, China |

| Leakage Circuit Breaker (4P) | |

| Circuit Breaker (1P) | |

| Power Supply Board | Schneider, France |

| Touchscreen | Weinview, Taiwan |

| Solid State Relay | Schneider, France |

| Intermediate Relay | Panasonic, Japan |

| Button | Changjiang, Jiangyin |

| Temperature Controller | CKR |

| Thermocouple | Keyang |

| Heating Tube | Anna, Shenzhen |

| Cylinder | Airtac, Taiwan |

| Solenoid Valve | |

| Magnetic Sensor | ARK, Korea |

| Proximity Switch | Tiangong, Shenzhen |

This Automatic Film Overwrapping and Sealing Machine is the ideal choice for manufacturers requiring adaptable, efficient, and user-friendly packaging solutions for high-quality, tamper-evident sealing of boxed products. With its advanced servo system, modular control, and comprehensive safety features, it stands out as a reliable and versatile asset in diverse production environments.

1. Automatic Feeding

In the feeding phase, the machine automatically transports the items to the designated positioning area. This process uses a linear feed design, ensuring stable and orderly movement of items into the packaging workflow, minimizing manual handling and increasing efficiency.

2. Film Feeding and Cutting

The machine draws packaging film from the roll and accurately cuts it to the appropriate length based on product dimensions. Dual servo motors control the film length, allowing for easy adjustments to accommodate different packaging specifications.

3. Film Folding

The machine folds the film around the product, wrapping it entirely. The folding system uses a precision mechanical structure to ensure the film edges are neat and closely aligned with the product surface, enhancing the overall appearance.

4. Heat Sealing

After folding, the heat sealing unit activates to secure the folded edges. The PLC-controlled heat sealing process ensures that the seal is tight without damaging the film, meeting packaging integrity requirements.

5. Edge Folding and Shrinking

Following heat sealing, the machine folds the film edges for a cleaner finish. For specific products, a heat-shrink option can be activated to make the film fit closely to the item, achieving a 3D wrap effect.

6. Finished Product Output

The wrapped products are automatically conveyed to the output section, where they are collected as finished items. The conveyor system is designed to prevent scratching, ensuring that the packaging remains intact and visually appealing. Products can then proceed directly to further inspection or downstream packaging steps.

7. Waste Collection

Excess film from the cutting and folding stages is collected through the waste recovery system, reducing material waste and keeping the workspace clean.

8. Tear Strip and Coding (Optional)

The machine can be equipped with an optional tear-strip and coding device. The tear-strip allows for easy opening of the package, while the coding device can print production dates, batch numbers, and other traceable information on the film.

9. Safety Protection and Fault Alarms

The machine includes multiple safety mechanisms. If issues such as jamming or misfeeds are detected, the machine will automatically stop and alert the operator to ensure safety. The PLC and touchscreen interface provide real-time monitoring and fault diagnostics, making it easy for operators to perform timely maintenance.

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.