Automatic tube filling and ultrasound sealing machine

- Цена

- $13,300

The Fully Automatic Tube Filling and Ultrasonic Sealing Machine is a high-precision, efficient solution tailored for manufacturers in the cosmetics, pharmaceutical, food, and chemical industries. This machine integrates advanced filling and ultrasonic sealing technologies to ensure accurate dosing, secure seals, and smooth operations, enhancing production quality and output.

Automatic Tube Feeding and Positioning

The system uses an advanced tube feeder to automate the loading and positioning of tubes onto the rotary worktable. With precision sensors and alignment arms, each tube is positioned correctly to avoid misalignment and ensure a seamless transition through each stage. This feature supports continuous production, minimizing manual intervention and maximizing efficiency.

High-Precision Filling Mechanism

Equipped with a high-precision dosing pump, this machine can accurately fill tubes with a variety of products, from thin liquids to thick creams and gels. The servo-controlled filling mechanism allows for easy volume adjustments, ensuring consistent fills without overflow or underfill. The anti-drip filling nozzles help maintain a clean workspace, eliminating waste and ensuring precise dosing at high speeds.

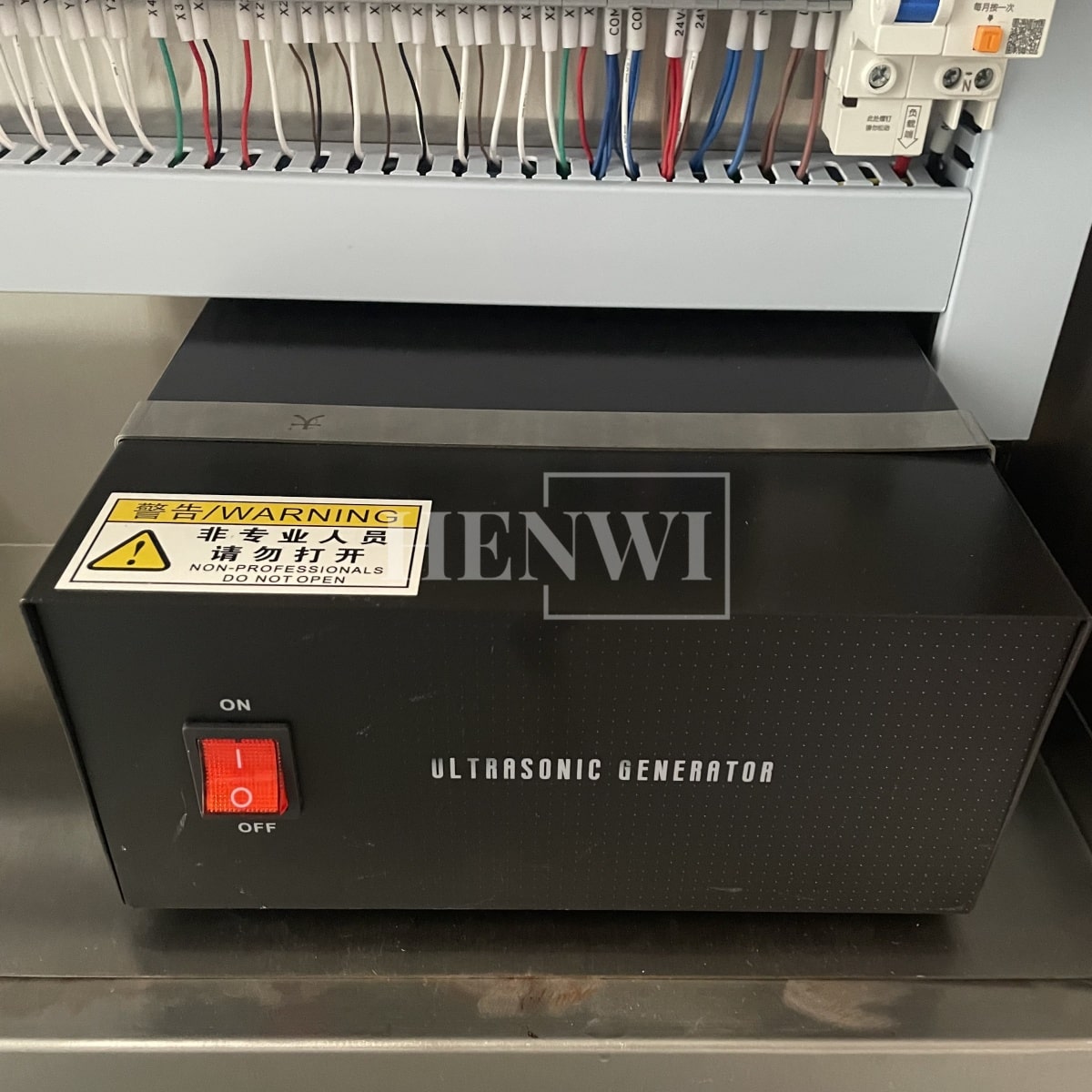

Ultrasonic Sealing Technology

The ultrasonic sealing unit provides a fast, strong, and secure seal, ideal for various soft tube materials like plastic and laminate. Ultrasonic waves generate localized heat at the seal area, bonding the tube ends without affecting the contents or damaging the tube’s structure. This sealing technology ensures a clean, professional finish and minimizes product contamination, making it suitable for high-quality and delicate formulations.

Precise Trimming System

After sealing, the excess material at the tube end is trimmed to create a neat and uniform finish. The trimming unit is equipped with adjustable cutting blades that cater to various tube diameters, ensuring a clean appearance and consistency across all products. This step enhances the tube's final appearance and prepares it for subsequent packaging stages.

Integrated Coding System

For batch and product traceability, the machine includes a coding system that applies production dates, batch numbers, and expiration dates to each tube. Coding methods can include inkjet printing, laser marking, or embossing based on specific requirements. This feature helps manufacturers meet regulatory standards, ensuring each product is easily traceable.

User-Friendly Touch Screen Interface

The machine’s touch screen control panel offers intuitive control over settings like filling volume, sealing intensity, and chiller temperature. The interface displays real-time data and alerts, including error diagnostics and maintenance notifications, allowing operators to optimize machine performance and quickly address issues.

Durable Transmission System

The machine’s robust transmission system ensures smooth and synchronized operation across all stages of production. Built with high-quality gears, belts, and motors, it provides stable motion with minimal vibration, extending the life of machine components and ensuring consistent, high-quality output at high speeds.

High-Throughput Production

Designed for fully automatic, high-speed production, this machine supports continuous output with minimal downtime, making it ideal for large-scale manufacturing. Adjustable speed controls enable operators to match production rates to specific batch requirements, providing flexibility across various product lines.

This Fully Automatic Tube Filling and Ultrasonic Sealing Machine offers unmatched precision, durability, and efficiency, making it a valuable asset for manufacturers seeking reliable, high-quality equipment to meet demanding production requirements.

Parameter

| Tube type: Plastic tube, Multiple tube |

| Filling range: A.6-60ml, B.10-120ml, C.25-250ml, D.50-500ml |

| Sealing type: Ultrasonic sealing |

| Capacity: 1300-1800 tubes/hour |

| Number of work positions: 10 |

| Safety protection: overload protection |

| Filling nozzle: Anti-drop |

| Filling accuracy: ±1% |

| Sealing shape: Flat tail, curved tail, special-shaped tail |

| Applicable tube diameter: 12-50mm |

| Applicable tube height: 50-250mm |

| Automatic detection function: No work without tube |

| Tube loding: Automatic |

| Air pressure: 0.6-0.7Mpa |

| Air comsumption: 0.3m3/min |

| Power: 2.6KW |

| Voltage: 220V/50Hz |

| Working air pressure: 0.4-0.6Mpa |

| Machine size: 1590×1400×1650mm |

| Machine weight: 450kgs |

| Touch screen: Weinview |

| PLC: HCFA |

| Sensor: Panasonic |

| Inverter: Delta |

| Ultrasonic frequency: 20kHz |

| Pneumatic components: AirTac Taiwan |

| Electrical components: Delixi, CHNT, Schneider |

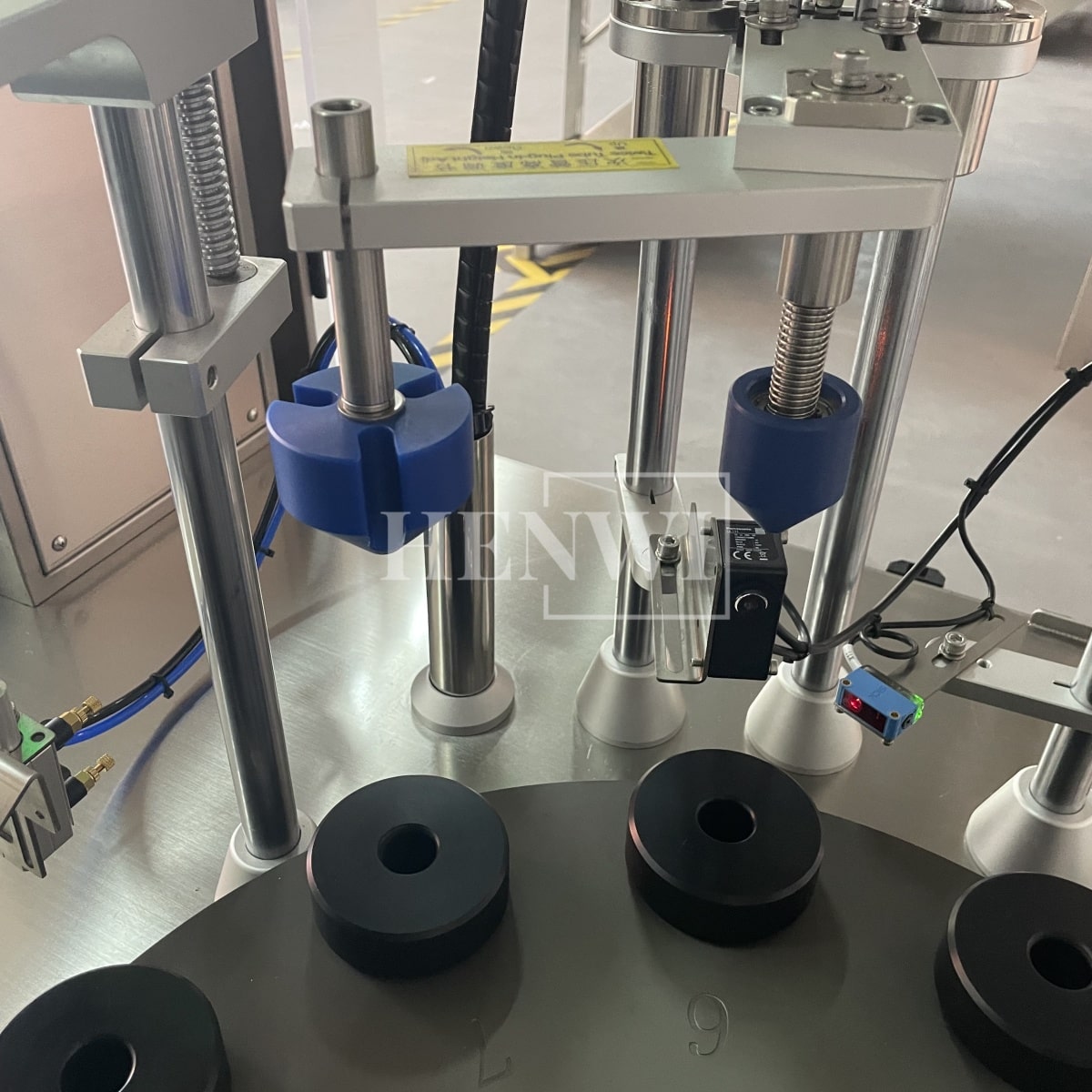

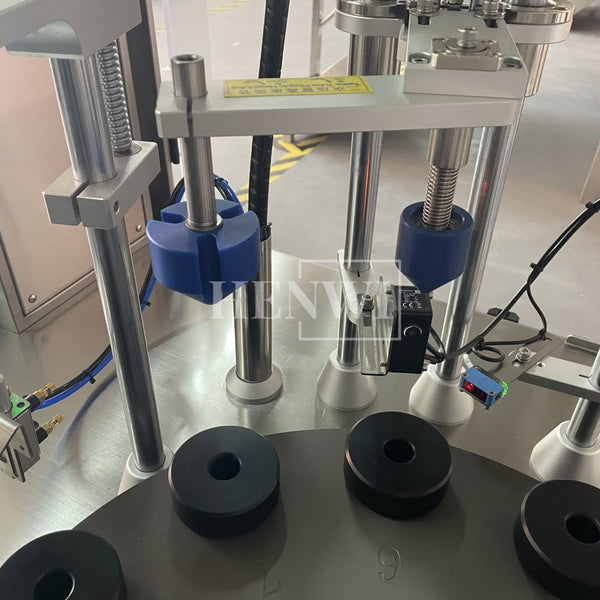

Rotary Worktable

This rotary worktable system integrates multiple processes into a streamlined, automated workflow, including:

This rotary worktable system integrates multiple processes into a streamlined, automated workflow, including:

Tube Feeding: Automated placement of tubes onto the worktable.

Positioning: Precise alignment of tubes for accurate processing.

Filling: Dispenses product into tubes with precise volume control.

Ultrasonic sealing: Ensures secure, airtight sealing of tube ends.

Coding: Applies batch codes or production information onto the tube.

Cutting: Trims excess material from the tube end post-sealing.

Ejection: Releases finished tubes from the worktable for collection.

Touch Screen

The Touch Screen interface offers a user-friendly control panel where operators can monitor and adjust machine settings, including speed, volume, temperature, and coding parameters. It also features error detection and diagnostic functions, allowing operators to quickly troubleshoot and maintain optimal machine performance.

Tube Feeding

The Tube Feeding system automates the process of placing empty tubes onto the worktable. Equipped with a tube sorting mechanism, this system ensures each tube is positioned upright and in the correct alignment for subsequent processing. It increases production efficiency by reducing manual handling, providing a smooth workflow for high-speed operations.

The Tube Feeding system automates the process of placing empty tubes onto the worktable. Equipped with a tube sorting mechanism, this system ensures each tube is positioned upright and in the correct alignment for subsequent processing. It increases production efficiency by reducing manual handling, providing a smooth workflow for high-speed operations.

Positioning

The Positioning mechanism utilizes sensors to accurately align each tube before filling. This guarantees precise label or seam alignment, ensuring that each tube is correctly positioned for the filling, sealing, and coding stages. This process minimizes errors, reduces material waste, and ensures uniform output quality.

The Positioning mechanism utilizes sensors to accurately align each tube before filling. This guarantees precise label or seam alignment, ensuring that each tube is correctly positioned for the filling, sealing, and coding stages. This process minimizes errors, reduces material waste, and ensures uniform output quality.

Filling

The Filling system is designed to handle a variety of product consistencies, from liquids to thick creams. With precise volumetric controls, the filling nozzle dispenses the exact amount of product required, reducing overfill or underfill. It supports a range of filling volumes to meet various production needs and ensure consistent, accurate filling every time.

The Filling system is designed to handle a variety of product consistencies, from liquids to thick creams. With precise volumetric controls, the filling nozzle dispenses the exact amount of product required, reducing overfill or underfill. It supports a range of filling volumes to meet various production needs and ensure consistent, accurate filling every time.

Ultrasonic Sealing with Coding

Ultrasonic Sealing with Coding Function: This system uses ultrasonic waves to create strong, leak-proof seals on soft tubes while precisely coding each tube with batch, date, or other traceable information. The integrated design allows for high-speed, clean sealing and coding in a single, efficient step, ensuring product integrity and compliance with traceability requirements.

Ultrasonic Sealing with Coding Function: This system uses ultrasonic waves to create strong, leak-proof seals on soft tubes while precisely coding each tube with batch, date, or other traceable information. The integrated design allows for high-speed, clean sealing and coding in a single, efficient step, ensuring product integrity and compliance with traceability requirements.

Cutting

The Cutting system trims excess material from the sealed end of each tube, providing a neat, uniform appearance. This process enhances the final presentation of the product while ensuring that all tubes have a consistent, professional finish, ready for retail packaging.

The Cutting system trims excess material from the sealed end of each tube, providing a neat, uniform appearance. This process enhances the final presentation of the product while ensuring that all tubes have a consistent, professional finish, ready for retail packaging.

Ejection

The Ejection mechanism safely releases the processed tube from the worktable into a collection bin. This automated ejection ensures that each tube is promptly removed after processing, allowing for uninterrupted operation and reducing manual handling. It maximizes output and maintains a smooth production line.

The Ejection mechanism safely releases the processed tube from the worktable into a collection bin. This automated ejection ensures that each tube is promptly removed after processing, allowing for uninterrupted operation and reducing manual handling. It maximizes output and maintains a smooth production line.

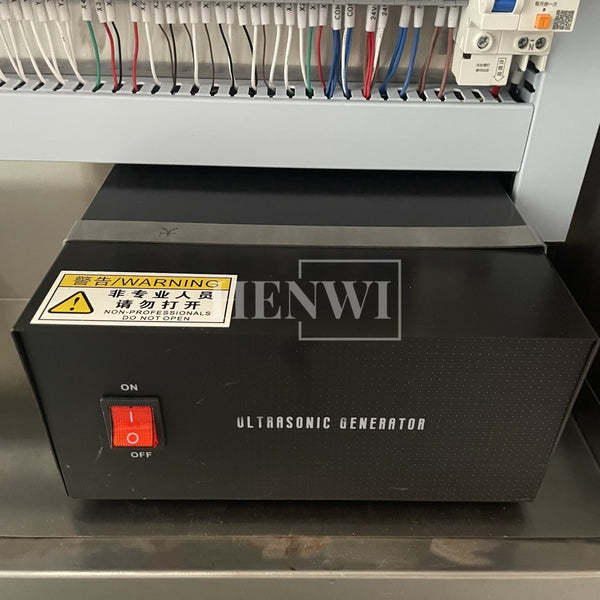

Electric Box

The Electric Box houses all of the machine’s electrical components, including circuitry and safety switches. Designed for easy access and maintenance, this box ensures stable power supply and controls the machine’s automation functions. It is equipped with protective features to prevent overload and ensure operator safety.

Automatic material feeder

Fault Alarm Light

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.