3000L Vaccum Emulsifying Mixer GD

- Цена

- $41,800

The **vacuum heating lifting homogenizing emulsifier with oil and water phases** is a specialized piece of equipment designed for emulsifying, homogenizing, heating, and mixing processes. It integrates advanced features such as vacuum suction, heating, cooling, lifting, and a dual-phase system for both oil and water phases. This makes it ideal for producing high-quality emulsions, creams, lotions, and other products that require thorough mixing of oil and water phases. It is widely used in industries such as cosmetics, pharmaceuticals, food, and chemicals. Below is a detailed description of the equipment:

### 1. **Main Functions**

- **Vacuum System**: The equipment is equipped with a vacuum pump to create a low-pressure environment. This system helps to remove air bubbles from the product during the mixing process, ensuring a smoother, denser final product with no air inclusions, thus improving the texture and quality.

- **Heating and Cooling**: The machine features a jacketed tank that allows for both heating and cooling processes. Electric heating, steam heating, or thermal oil heating can be used to control the temperature of the product precisely. After heating, cooling water can be circulated through the jacket to lower the temperature quickly, ensuring proper temperature management throughout the process.

- **Lifting Mechanism**: The homogenizing head and lid can be raised or lowered using an electric or hydraulic system, which facilitates easy access for material addition, cleaning, and maintenance.

- **Homogenizing and Emulsification**: The high-shear homogenizer enables thorough mixing, emulsification, and dispersion of oil and water phases, breaking down droplets and particles to a fine size, creating a stable emulsion with a smooth texture.

### 2. **Oil and Water Phase Tanks**

- **Dual-Tank System**: The equipment includes separate oil phase and water phase tanks. These tanks allow for the preheating and mixing of oil- and water-based ingredients separately, ensuring that the two phases are at the correct temperature before being combined in the main emulsifying tank.

- **Efficient Transfer**: After heating and mixing in the oil and water tanks, the ingredients can be automatically transferred into the main emulsifying tank using vacuum suction, which minimizes the introduction of air and maintains the integrity of the product.

- **Heating and Mixing**: Both the oil and water phase tanks are equipped with heating elements and mixers to ensure that the ingredients in each tank are properly heated and mixed before they are combined in the main emulsifying tank.

### 3. **Main Emulsifying Tank**

- **Jacketed Tank for Heating and Cooling**: The main tank is jacketed to allow for heating or cooling of the product as needed. This ensures precise temperature control for sensitive materials during both the emulsification and homogenization processes.

- **High-Shear Homogenizer**: Located at the bottom of the tank, the high-shear homogenizer creates a powerful vortex that ensures thorough emulsification by breaking down oil and water droplets into micron or even nano-sized particles. This results in a stable and smooth emulsion with excellent texture.

- **Scraper Stirrer**: The tank is equipped with a scraper stirrer that rotates along the tank’s inner walls. The scraper ensures that all material is constantly in motion, preventing it from sticking to the walls and ensuring even heating or cooling.

### 4. **Vacuum System**

- **Vacuum Suction for Material Transfer**: The vacuum system not only removes air from the final product but also allows for the suction of raw materials into the main emulsifying tank from the oil and water phase tanks. This helps reduce contamination risks and prevents air from being introduced into the product during material transfer.

- **Deaeration**: The vacuum system also removes air bubbles formed during the mixing and emulsification process, ensuring that the finished product has a smooth, air-free texture, and preventing issues like oxidation or separation during storage.

### 5. **Control System**

The **control system** of the vacuum heating lifting homogenizing emulsifier comes with two options:

- **Standard Button Control System**: The default configuration is a user-friendly button-operated control system. This system allows for straightforward operation, enabling the operator to control essential functions such as heating, mixing speed, vacuum level, and homogenizing manually through push buttons.

- **Optional PLC + Touchscreen Control System**: For enhanced automation and precision, the equipment can be upgraded with an optional PLC (Programmable Logic Controller) and touchscreen interface. This system offers more advanced features, allowing the operator to set and monitor parameters such as temperature, mixing speed, homogenizing time, and vacuum levels with greater accuracy. The touchscreen interface provides a more intuitive and automated experience, making it ideal for larger-scale or more complex production processes.

### 6. **Safety and Cleaning**

- **Safety Features**: The emulsifier is equipped with multiple safety features, such as overload protection, emergency stop buttons, and vacuum pressure monitoring to ensure safe operation.

- **Easy Cleaning and Maintenance**: The lifting system and the design of the equipment make it easy to clean. The smooth inner surfaces and detachable components allow for thorough cleaning, ensuring compliance with hygiene standards, especially in the pharmaceutical and cosmetics industries.

Application

The vacuum heating lifting homogenizing emulsifier is used in a variety of industries due to its multifunctionality:

- **Cosmetics Industry**: Ideal for producing lotions, creams, serums, and other skincare products. The oil and water phase tanks ensure thorough mixing and emulsification of ingredients, resulting in a smooth, stable product.

- **Food Industry**: Suitable for making sauces, dressings, and emulsified products that require fine dispersion and temperature control. The vacuum system ensures that the final product is free from air bubbles and has a smooth texture.

- **Pharmaceutical Industry**: Used for manufacturing ointments, emulsions, and creams where precise control over particle size, temperature, and mixing is required to ensure product efficacy.

- **Chemical Industry**: Applied in the production of paints, adhesives, and emulsions where uniform particle dispersion and stable emulsions are critical for product performance.

Parameter

| Model: HWVM-GD-3000L |

| Working capacity: 3000 Liters |

| Heating method: electric (Steam option) |

| Mixing type: Upper frame oar scraper mixer |

| Mixing motor power: 11KW, Siemens motor |

| Mixing frequency inverter: 11KW |

| Mixing speed: 0-65rpm |

| Homogenizer type: Bottom homogenizer |

| Homogenizer power: 18.5KW, Siemens motor |

| Homogenizer frequency inverter: 18.5KW |

| Homogenizer speed: 0-3000rpm(50Hz)/0-3600rpm(60Hz) |

| Vacuum system: Water cycle vacuum pump, power: 5.5KW |

| Control method: Button control |

| Frequency inverter: Delta |

| Electrical components: Delixi |

| Jacket: Double jacket,3 layers |

| Tank's materials: Inner layer 8mm/SUS316, Middle layer 6mm/SUS304, Outer layer 3mm/SUS304 |

| Water and oill phase tank: 2400Litres /1800Litres, With mixing and heating function |

Control Panel |

|

The button control panel of the vacuum homogenizer is the core part of the operation and control equipment, usually with an intuitive interface and multiple functions. The following is a detailed description of the button control panel: ### 1. **Panel layout** |

Emulsifying Homogenizer |

|

The homogenizer function in the vacuum homogenizer is one of its key components, which is specially used to achieve efficient material homogenization and emulsification. The following is a detailed description of this function: ### 1. High shear homogenization technology ### 2. Efficient mixing and dispersion ### 3. Advantages of vacuum operation ### 4. Thermal management function ### 5. High efficiency in production ### 6. Easy to clean and maintain ### 7. Wide range of applications |

Frame Wall Scraper Mixing |

|

The one-way scraping stirring function of the vacuum homogenizer is an important part of its stirring system. It is mainly used to fully mix the materials and prevent the materials from adhering to the wall of the emulsifier. It can ensure that the materials are always evenly distributed during the emulsification process, avoiding dead corners and uneven mixing, and is particularly suitable for high-viscosity and easy-to-adhere materials. ### Working principle of the one-way scraping stirring function: |

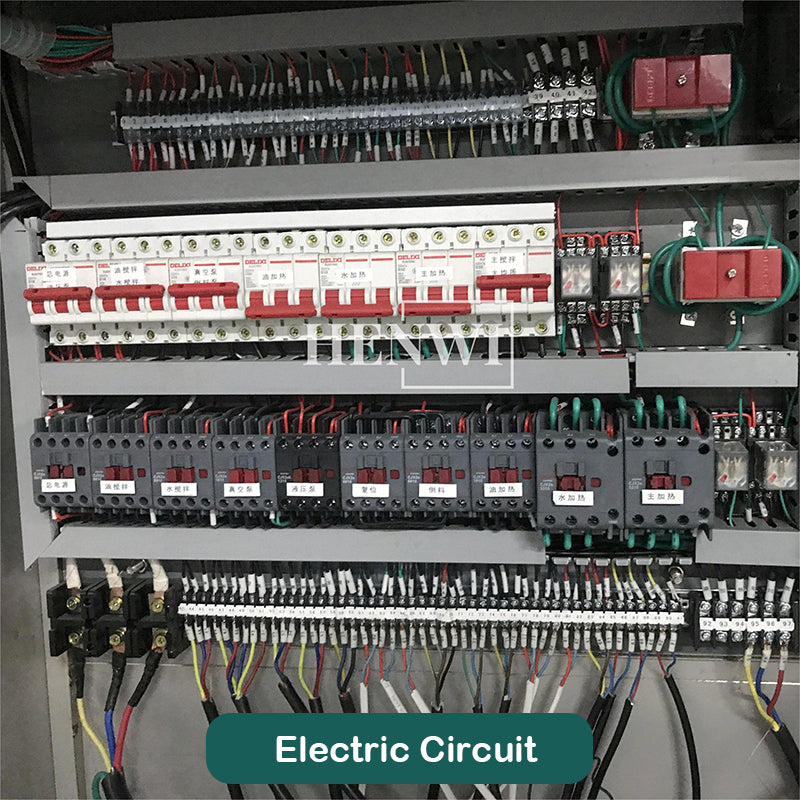

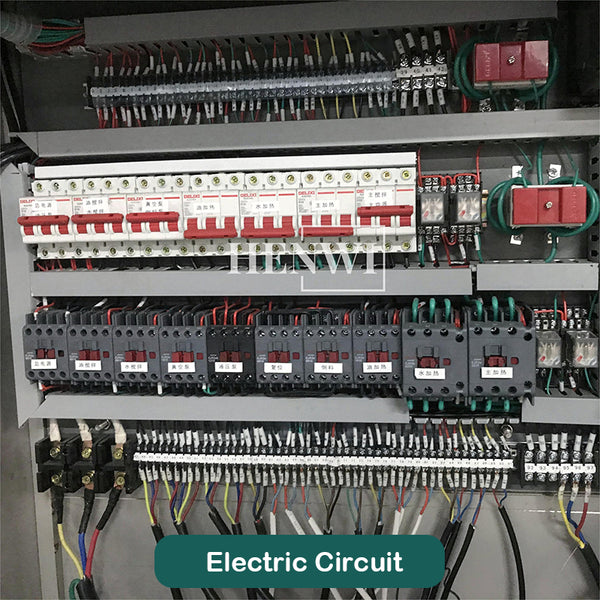

Electrical Box |

|

The internal structure of the electrical box of the vacuum homogenizer is complex, containing a variety of electrical components and control systems to ensure the safe, efficient and stable operation of the equipment. The following is a detailed description of the interior of the electrical box: ### 1. **Internal structure of the electrical box** ### 2. **Main electrical components** ### 3. **Power supply and signal wiring** ### 4. **Monitoring and protection system** ### 5. **Control panel** ### 6. **Safety device** ### 7. **Heat dissipation design** |

Multifunctional Lid |

|

The multifunctional cover of the vacuum homogenizer integrates multiple functional components to improve operating efficiency and product quality. The following is a detailed description of the multifunctional cover including components such as feed filter, vacuum pressure gauge, vacuum drain valve, CIP spray ball, visual light, window and flavor funnel: ### 1. **Overall structure and material** ### 2. **Functional components** ### 3. **Safety Design** ### 4. **Cleaning and Maintenance** |

Oil & Water Phase |

|

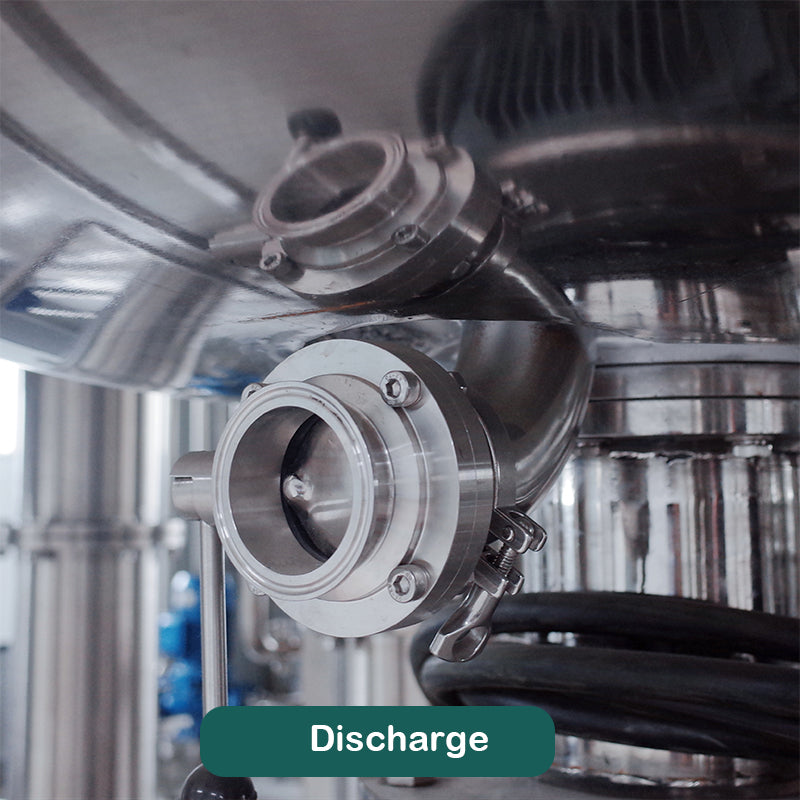

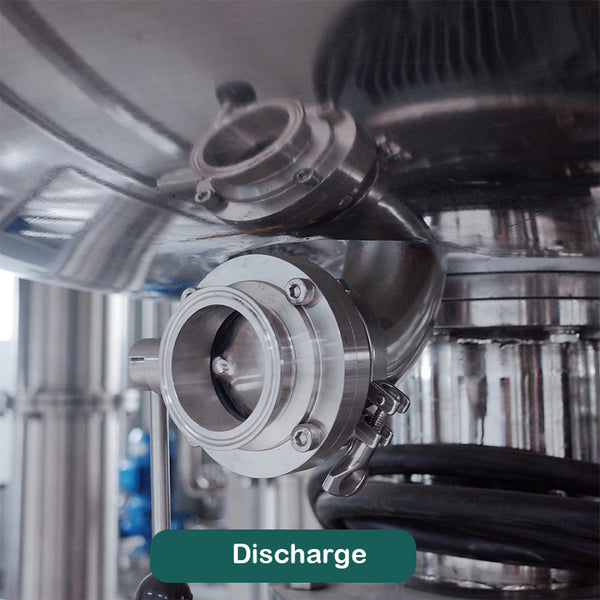

The oil-water phase part of the vacuum homogenizer is one of the core functions of the equipment, which is specially used to preheat and disperse the oil-water raw materials. The following is a detailed description of the oil-water phase, including its heating, dispersion and other functions: ### 1. **Oil-water phase structure** ### 2. **Heating function** ### 3. **Dispersion function** ### 5. **Feeding and discharging of oil-water phase** |

| Vacuum Pump |

|

The vacuum function of the vacuum homogenizer is one of its core features. Its main function is to exhaust the air in the emulsifying pot through the vacuum system, so that the materials can be mixed, homogenized and emulsified in a vacuum environment without bubbles. This function plays an important role in ensuring product quality, improving emulsification effect and production efficiency. ### Working principle of vacuum function: The vacuum system uses a vacuum pump to evacuate the emulsifying pot, reduce the air pressure in the container, and put it in a low pressure or vacuum state. In this environment, the material will not be mixed with bubbles during the stirring and homogenization process, ensuring the uniformity and stability of the product. ### Main functions of vacuum function: 1. **Prevent bubble formation**: Under vacuum conditions, air is extracted to avoid entrainment of air in the material during stirring or emulsification, thereby preventing the formation of bubbles. This is especially important for high-demand products such as pharmaceuticals and cosmetics, such as creams, essences, etc., which require smooth texture and uniform structure. 2. **Improve product stability**: Products without bubbles have better stability and are not prone to stratification, decomposition or oxidation problems. The vacuum environment can reduce the contact between materials and air, thereby reducing the possibility of oxidation reactions and extending the shelf life of the product. 3. **Improve emulsification effect**: The vacuum environment helps materials to mix more fully, especially for oil-water mixtures that need to be evenly dispersed. Through the action of the high shear homogenizer, the materials are more finely dispersed under vacuum, the emulsification effect is better, and the emulsion produced is more delicate and stable. 4. **Improve product density**: Products produced under a vacuum environment are usually denser, thicker and more uniform in texture, which is an important indicator for many high-end cosmetics or medicines. 5. **Prevent air pollution**: The vacuum system can also effectively prevent impurities, dust or pollutants in the air from entering the material, ensuring the purity of the product, especially suitable for production environments with high requirements for hygiene conditions in industries such as pharmaceuticals, cosmetics and food. ### Advantages of the vacuum function: - **High product quality**: By preventing bubble formation and reducing oxidation, the vacuum function ensures high-quality homogenization and emulsification, and the product is smooth and delicate. - **Improved operational efficiency**: Emulsification under vacuum helps to achieve the desired emulsification effect faster and more efficiently, reducing stirring and homogenization time. |

Heating System |

|

The interlayer electric heating function of the vacuum homogenizer is an important part of its heating system. It is mainly used to heat the material in the pot to the required temperature through electric heating elements to meet the requirements of different processes. The following is a detailed description of the interlayer electric heating function: 1. Interlayer design and structure 3. Temperature control system |

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.