Movable heating & mixing tank

- Price

- $2,200

The mobile heating stirring pot is an industrial equipment that integrates heating, stirring and moving functions. It is widely used in food processing, pharmaceutical, chemical and other industries for mixing, heating and reacting materials.

1. **Material**: Made of high-quality stainless steel 304 and 316L, the equipment is ensured to have excellent corrosion resistance and easy cleaning, and meets hygiene and food safety standards. Suitable for industries that require strict hygiene conditions.

2. **Heating method**: The equipment is equipped with a variety of heating methods to choose from, including electric heating, steam heating, thermal oil heating, etc. The heating is uniform and the temperature is controllable, which can meet the process requirements of different materials. Some equipment is also equipped with a jacket design for efficient heat transfer.

3. **Stirring system**:

- Equipped with a powerful stirring device, the stirring paddle is made of stainless steel 316L material, which can adapt to materials of different viscosities.

- The stirring speed is adjustable to meet the needs of different processes from low-speed mixing to high-speed emulsification.

- Some stirring pots are also equipped with a scraping stirring system to prevent materials from sticking to the wall and improve stirring uniformity.

4. **Mobility**: The bottom of the pot is equipped with high-strength universal casters, which facilitates the flexible movement of the equipment in different working areas. The casters are usually equipped with brakes to ensure stability during work.

5. **Volume and specifications**: The capacity of the mobile heating and stirring pot can be customized according to customer needs. The common capacity ranges from tens of liters to thousands of liters, suitable for small-scale production to large-scale industrial applications.

6. **Operation and control**:

- Equipped with an easy-to-operate control panel, parameters such as heating temperature, stirring speed and time can be adjusted.

7. **Safety device**: The equipment is usually equipped with temperature sensors and safety valves to ensure safety during heating and stirring and prevent risks caused by overheating or overpressure.

8. **Application range**: Widely used in food processing (such as heating and stirring of syrups, jams, and dairy products), pharmaceutical production (such as mixing and heating of medicaments), chemical manufacturing (such as reaction and mixing of chemical liquids or semi-solids), and other industries that require mixing and heating treatment.

| Voltage | 220V/3-phases, 380V/3-phases |

| Mixing | Siemens motor, Speed: 0-65 rpm, Delta frequency inverter,

Stirring blade:SUS316L, thickness 10mm, Scraper material: PTFE A board, 12mm, white,Flange coupling connection, German Burgmann mechanical seal, Japan NSK bearing |

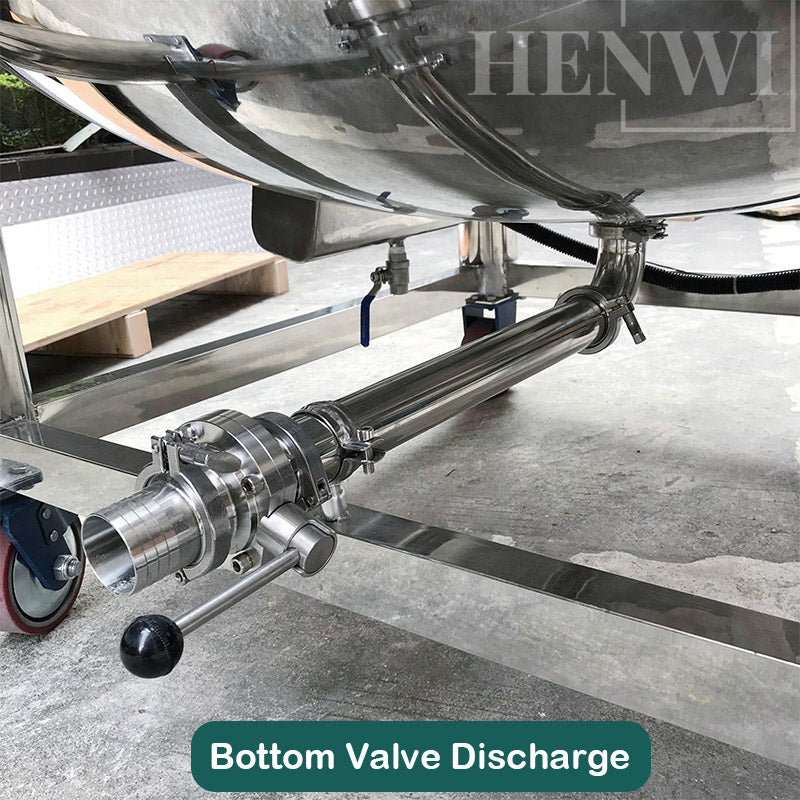

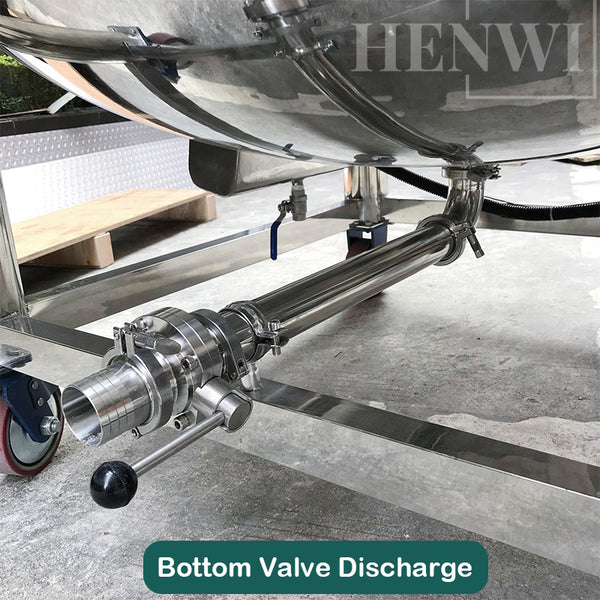

| Discharge | SUS316 butterfly valve |

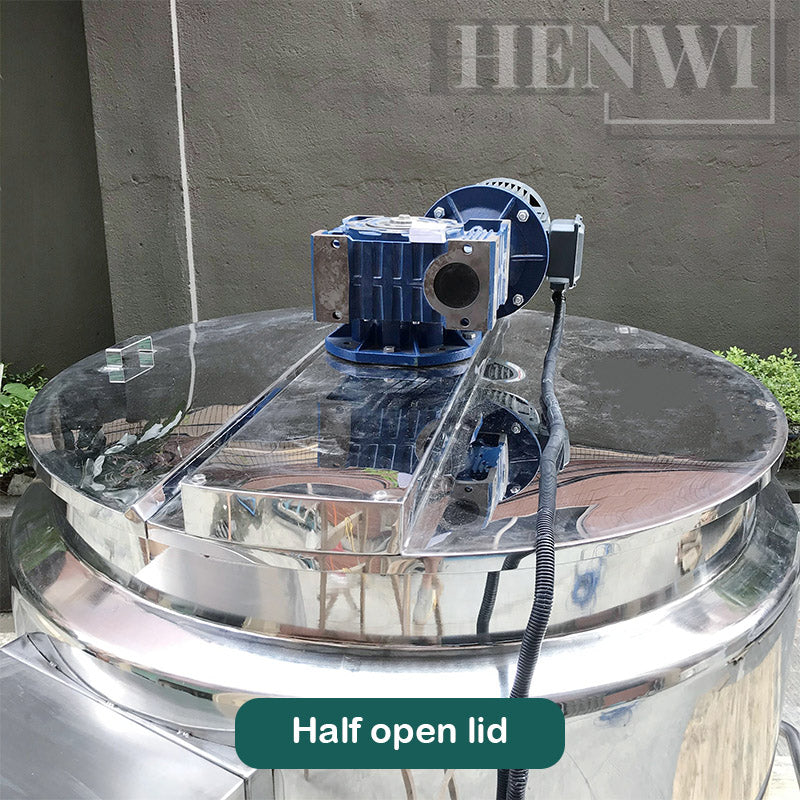

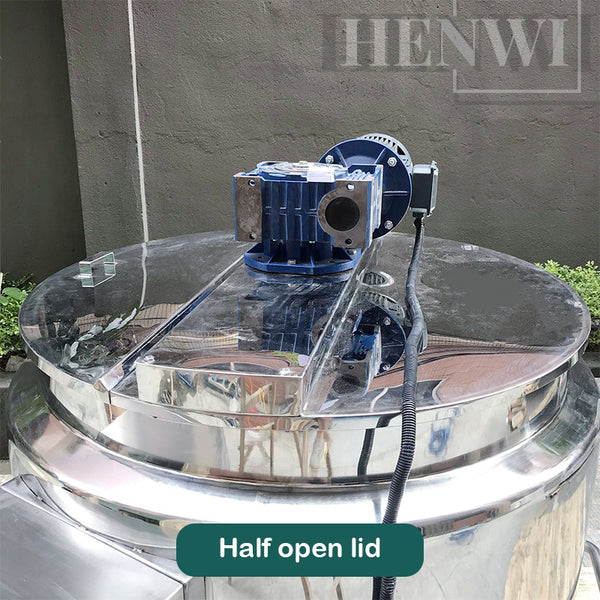

| Lid | SUS304, Half open lid |

| Control box | Temperature controller, switch button, power indicator, emergency switch |

| Double jackets |

Inner layer: SUS316L Middle layer: SUS304 Outer layer: SUS304 |

Control Panel

The control box is equipped with speed adjustment, a temperature meter, a voltmeter, a heating switch, an emergency stop, and various indicator lights for controlling the equipment.

Stirring system:

- Equipped with a powerful stirring device, the stirring paddle is made of stainless steel 316L material, which can adapt to materials of different viscosities.

- The stirring speed is adjustable to meet the needs of different processes from low-speed mixing to high-speed emulsification.

- Some stirring pots are also equipped with a scraping stirring system to prevent materials from sticking to the wall and improve stirring uniformity.

Foldable Lid

The half-open cover makes it easy to add raw materials to the tank, while the half-open cover design allows gas or volatile substances to be released from the tank to prevent excessive internal pressure. The half-open cover design makes the tank more convenient to clean and maintain.

Heating heater

Heating in the tank prevents some substances from agglomerating or settling due to low temperatures, thus maintaining a smooth production process, such as melting wax or grease. Or it can ensure that certain ingredients are thoroughly mixed.

Bottom Valve Discharge

Discharge and sampling: The discharge port allows the raw materials or finished products in the storage tank to be discharged for subsequent processing or bottling. At the same time, it can also be used for sampling for quality inspection.

Pushing Handle

Push handles allow operators to easily move tanks, especially when they need to rearrange production line equipment or clean work areas. Overall, push handles on tanks are designed to increase operator convenience, safety, and efficiency when moving, adjusting, and maintaining tanks.

Wheels with Break

The machine is equipped with castors for easy movement within the production hall, making repositioning, cleaning and maintenance of the machine more efficient and labor-saving. The brake function ensures that the machine does not accidentally slide during movement.

Internal & external mirror polishing

The internal mirror polishing of stainless steel mobile sealed storage tanks is a key processing technology designed to improve the surface quality and performance of the inner wall of the tank. Its main purpose is to achieve a smooth and flat mirror effect through high-precision polishing.

1. **Smoothness**: The inner wall of the tank that has been mirror-polished is very smooth, and the smoothness can usually reach the level of Ra≤0.4μm. This high smoothness reduces the surface roughness and prevents materials such as liquids or powders from adhering to the inner wall of the tank, making it easier to clean and maintain, and meeting the hygiene standards of the food, pharmaceutical and other industries.

2. **Corrosion resistance**: A dense passivation layer is formed on the polished stainless steel surface, which effectively improves the corrosion resistance of the tank, especially when storing acid, alkali or highly corrosive liquids, which can extend the service life of the tank.

3. **Anti-pollution performance**: Mirror polishing reduces tiny pores and rough areas, which can effectively reduce the risk of harboring contaminants or microorganisms and ensure the purity of stored materials, especially in applications with strict hygiene requirements, such as pharmaceuticals, biotechnology, food processing and other industries.

4. **Easy to clean**: Due to the smooth and seamless surface, residues and cleaning agents can be easily rinsed away after CIP (cleaning in place system), avoiding cross contamination caused by residue accumulation.

5. **Reduced friction**: When storing materials with high requirements for fluidity or mixing, mirror polishing can effectively reduce the friction between the material and the inner wall of the storage tank, ensuring smooth material flow and reducing retention.

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.