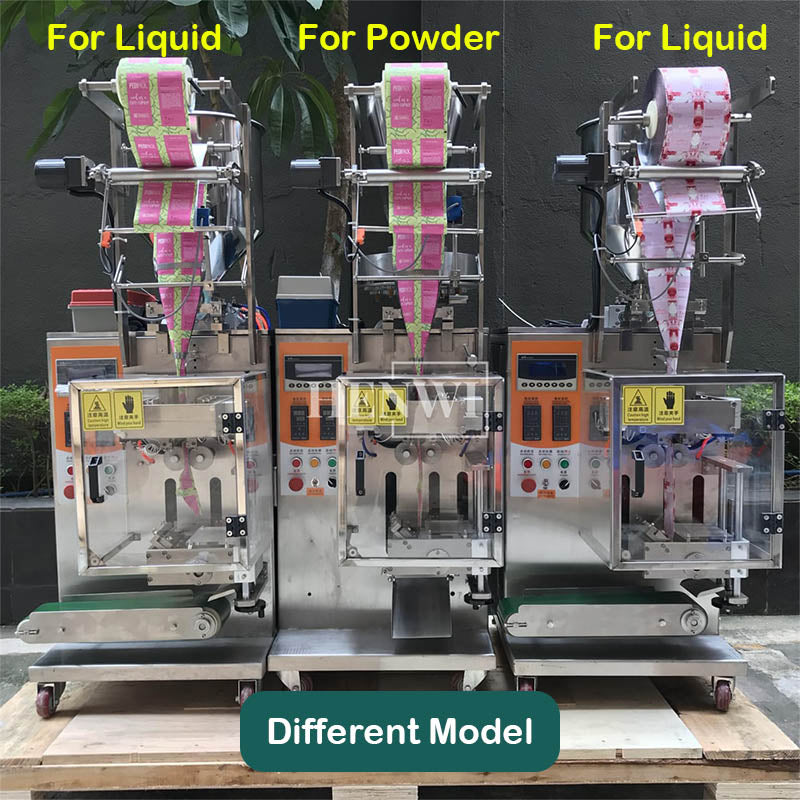

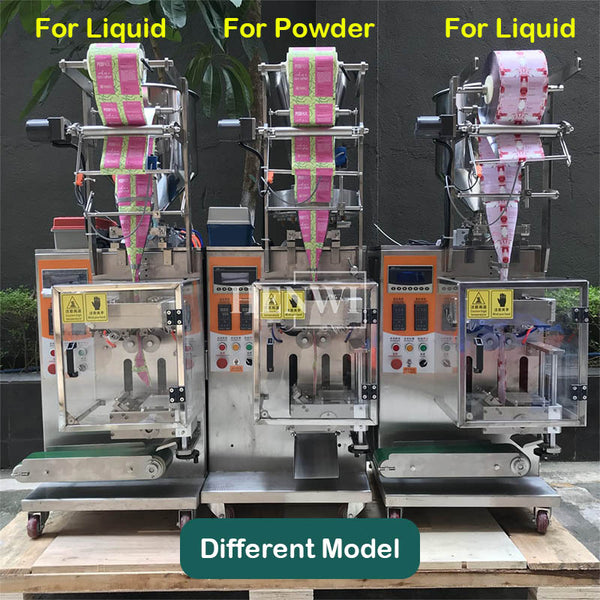

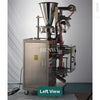

Automatic sachet powder filling and sealing machine 5-50g

- Price

- $4,800

Automatic Powder Pouch Packaging Machine

Product Overview:

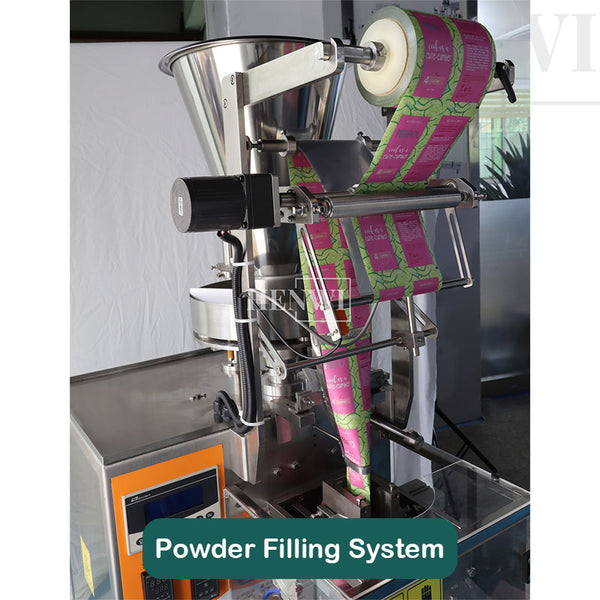

The Automatic Powder Pouch Packaging Machine is designed for precise and efficient filling of powdered products into flexible pouches, making it ideal for industries like food, pharmaceuticals, chemicals, and cosmetics. This machine handles a variety of powdered products, from spices and protein powders to pharmaceutical powders and detergents. It offers high accuracy in dosing, secure sealing, and reliable packaging quality, making it an essential tool for companies seeking consistent and hygienic powder packaging.

Key Features:

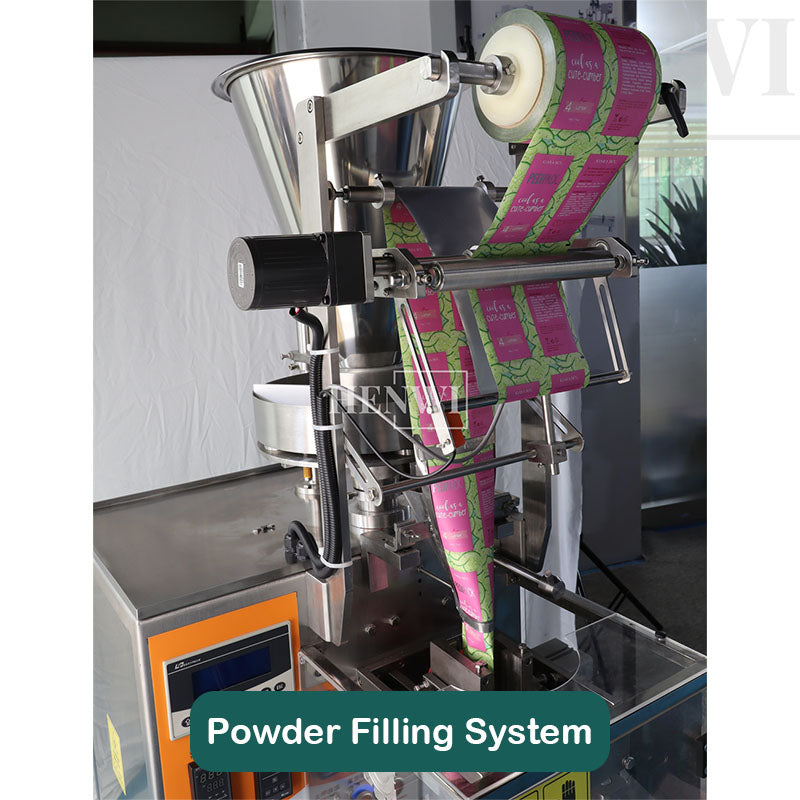

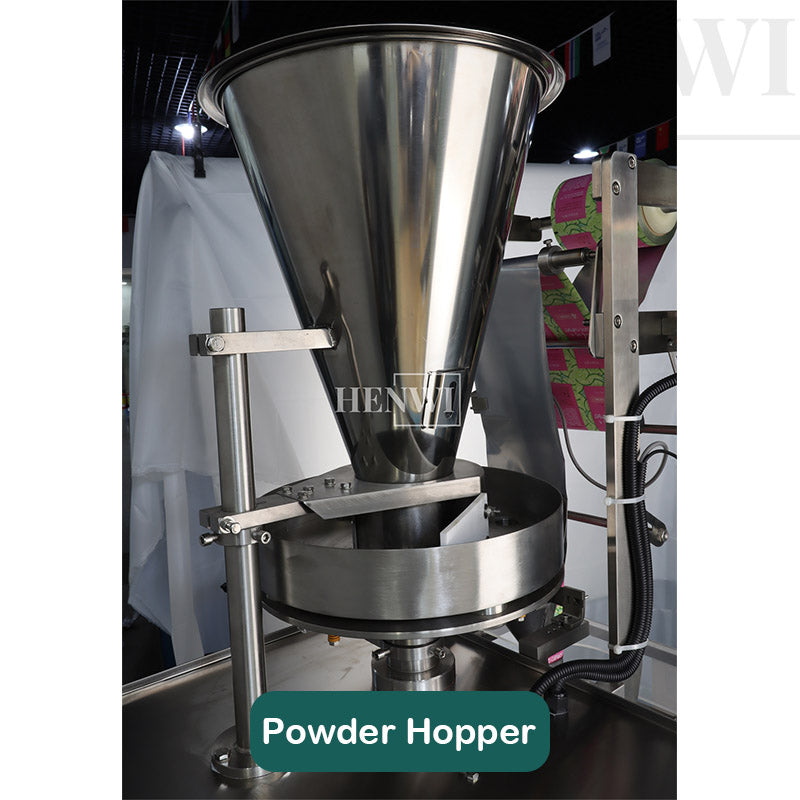

Precision Auger Filling System: Equipped with a high-accuracy auger filler designed specifically for powders, ensuring precise dosing in every pouch. This minimizes product wastage and ensures batch consistency across production runs.

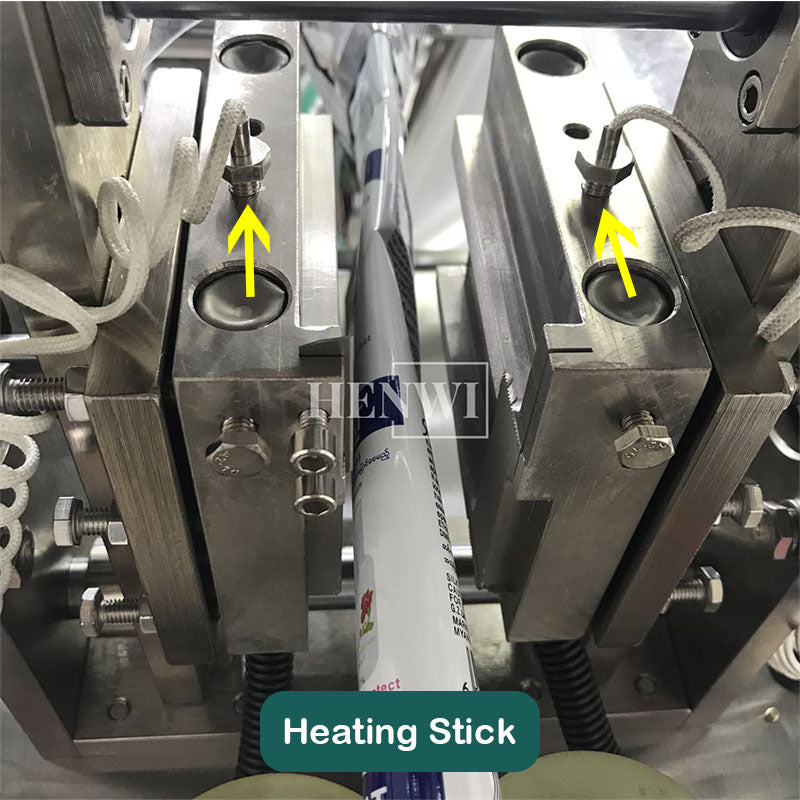

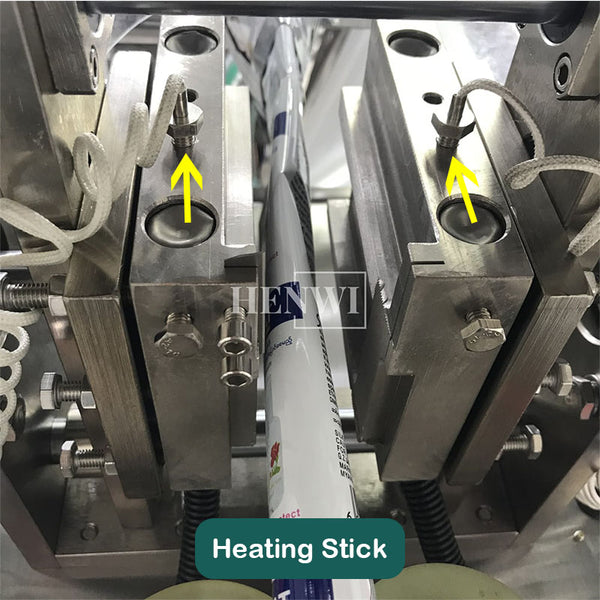

Heat Sealing Technology: The machine uses a robust heat-sealing mechanism to create secure, leak-proof seals. This extends product shelf life by protecting contents from moisture and air contamination.

Adjustable Pouch Size Compatibility: Capable of handling a wide range of pouch sizes, with adjustable settings for pouch width and length. This flexibility makes it suitable for various packaging formats, from small sample packs to larger retail sizes.

User-Friendly Touchscreen Interface: The intuitive control panel allows operators to easily set and monitor parameters such as fill volume, sealing temperature, and production speed. Real-time data and alerts ensure smooth operation and easy troubleshooting.

Stainless Steel Construction: Made with high-quality stainless steel for durability and hygiene, this machine is suitable for food and pharmaceutical-grade applications, ensuring long-term resistance to corrosion.

Automatic Pouch Loading and Alignment: Automatically loads and aligns pouches, which reduces manual intervention and increases production speed, making the process more efficient and reducing labor costs.

Optional Dust Extraction System: Equipped with a dust extraction feature to prevent powder leakage and maintain cleanliness around the filling area, which is especially beneficial for fine powders.

Applications: This machine is suitable for packaging a variety of powdered products, including:

Food & Beverage: Spices, protein powders, flour, powdered milk, and cocoa powder.

Pharmaceuticals: Medicinal powders, dietary supplements, and herbal powders.

Chemicals: Fertilizers, cleaning powders, and industrial chemicals.

Cosmetics: Face powders, body powders, and other fine powdered products.

Technical Specifications:

Production Speed: 20-50 pouches per minute, depending on product density and pouch size

Filling Volume: Adjustable for different pouch sizes, typically ranging from 5 g to 50 g

Pouch Width Range: 15-120 mm

Pouch Length Range: 40-180 mm

Power Requirement: 220V / 50Hz, 2.2 kW

Sealing Method: Heat sealing

Material Compatibility: Suitable for multi-layer films (PET/PE, NY/PE) and various laminated materials

Advantages:

High Accuracy: Ensures precise dosing and consistent packaging quality, minimizing product waste.

Enhanced Productivity: Automatic pouch loading, filling, and sealing functions increase production speed and efficiency.

Easy Operation and Maintenance: The touchscreen control panel simplifies operation, while the stainless steel design ensures ease of cleaning and durability.

Versatile Application: Suitable for a wide range of powdered products, with customizable options for different pouch sizes and materials.

The Automatic Powder Pouch Packaging Machine is an ideal solution for businesses seeking a reliable, efficient, and accurate powder packaging system. Its combination of precision, speed, and hygienic design meets the high demands of modern powder packaging, providing consistent, professional results across various industries.

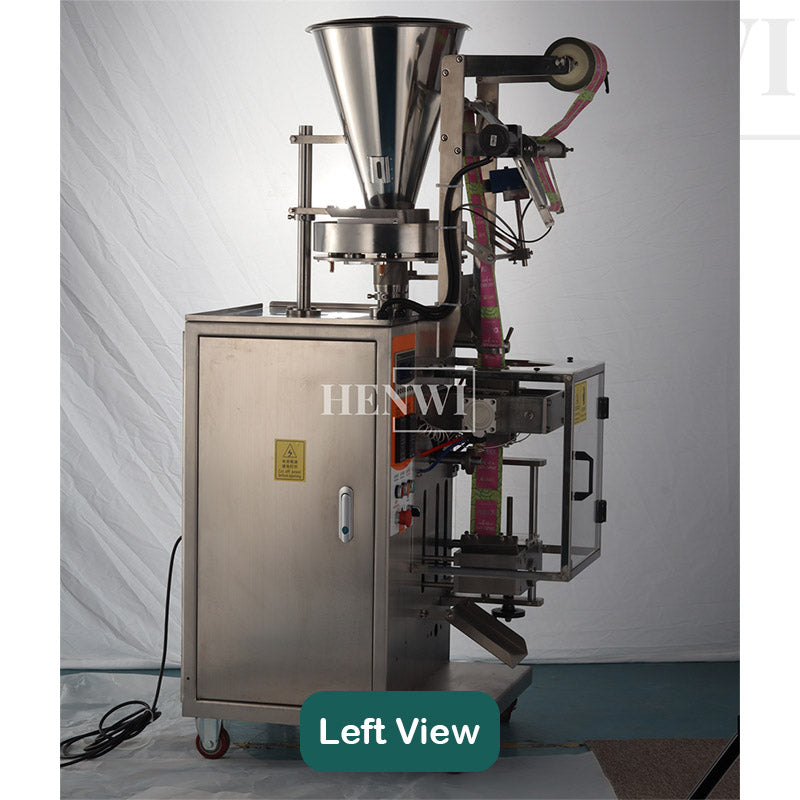

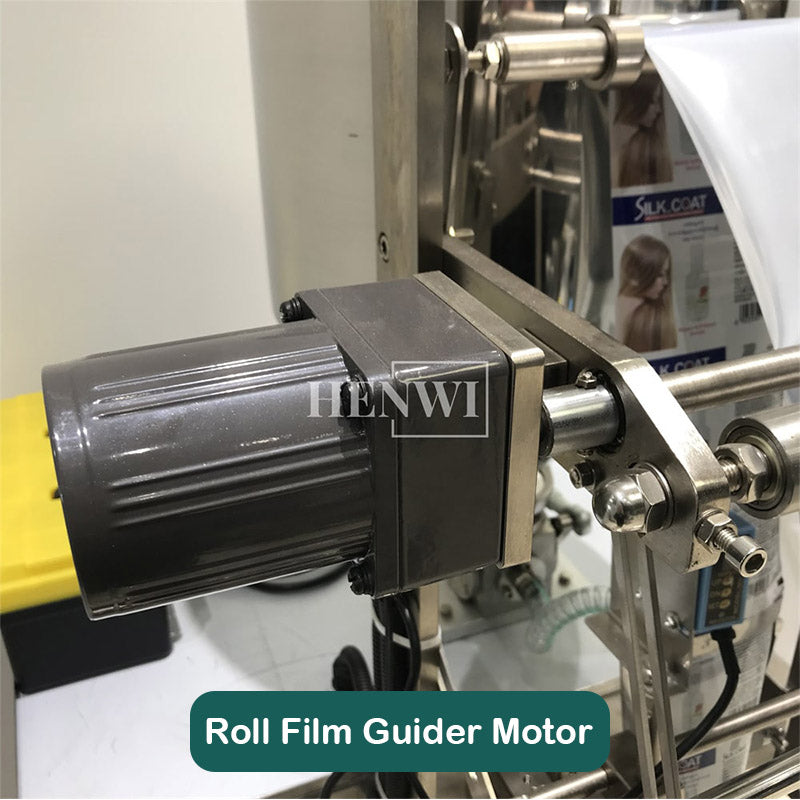

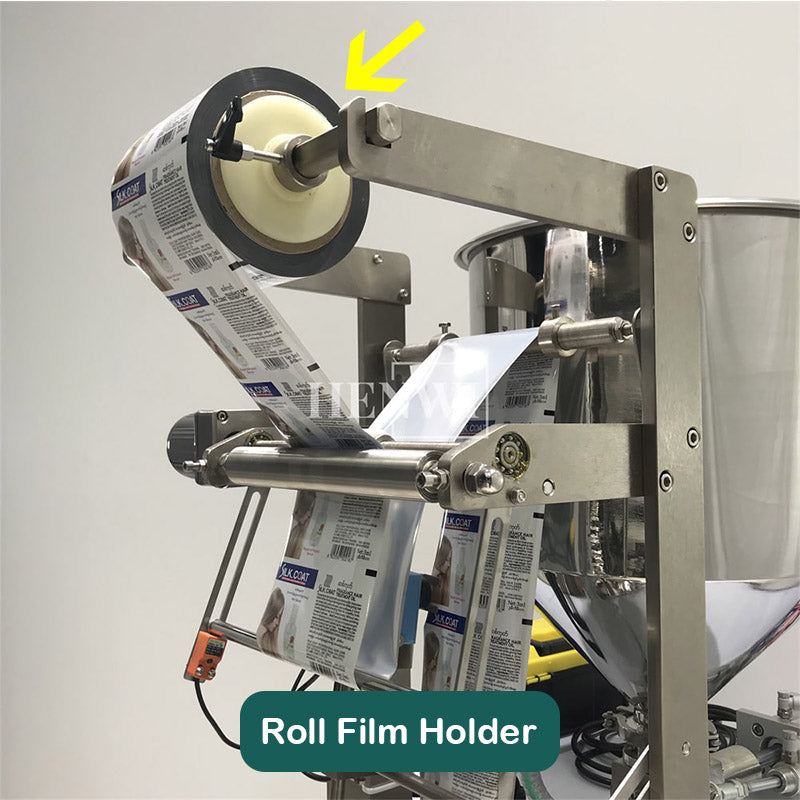

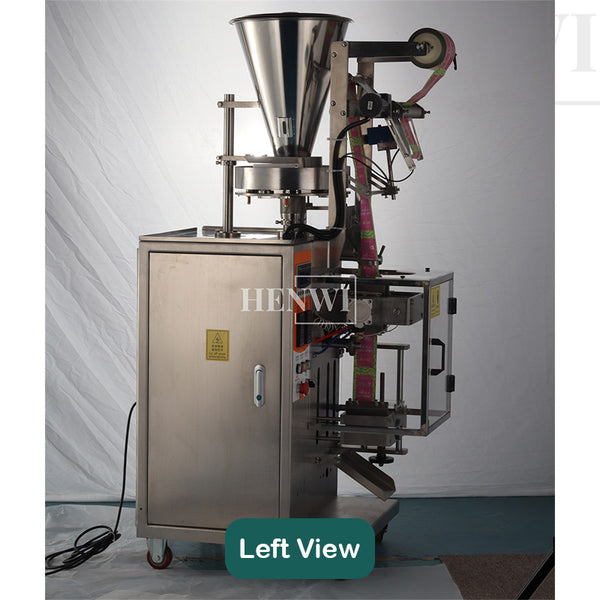

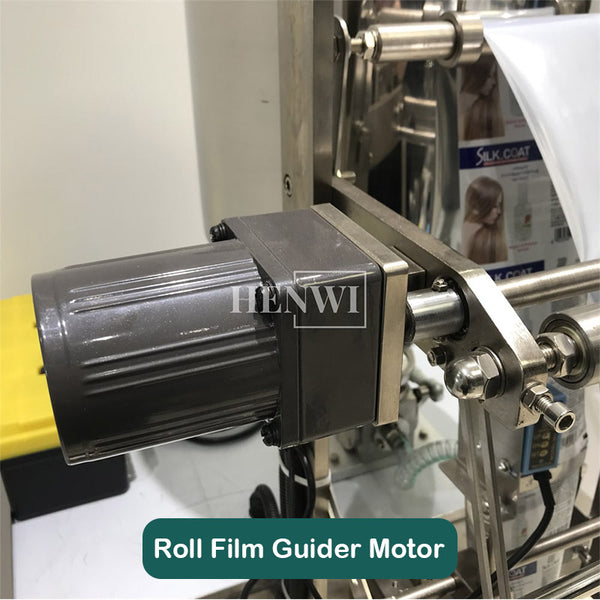

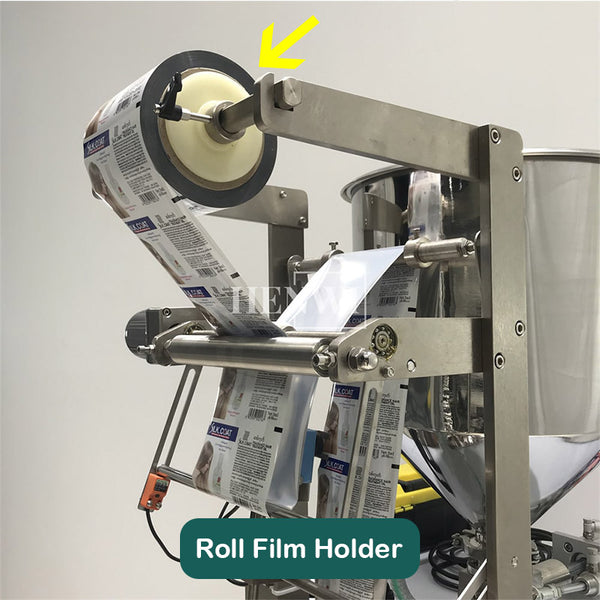

1. Film Roll Device

The film roll device is a key component of the automatic powder pouch packaging machine. It steadily unwinds packaging film from the roll, ensuring smooth delivery through precise drive and tension control systems. This prevents wrinkles or misalignment, laying a solid foundation for accurate packaging in subsequent steps.

2. Film Eye Mark Sensor

The film eye mark sensor detects color marks on the film for precise positioning of each pouch’s graphics and text. By sensing these marks, it automatically adjusts the film’s pull position, ensuring that each sealing and cutting operation aligns with the designated mark, maintaining consistency in the pouch appearance.

3. Film Pull Sensor

The film pull sensor monitors the film’s movement, ensuring it advances at a consistent speed. By accurately detecting the film's tension and displacement, it prevents slack or breakage, guaranteeing standard pouch sizes and contributing to the machine's efficient, stable operation.

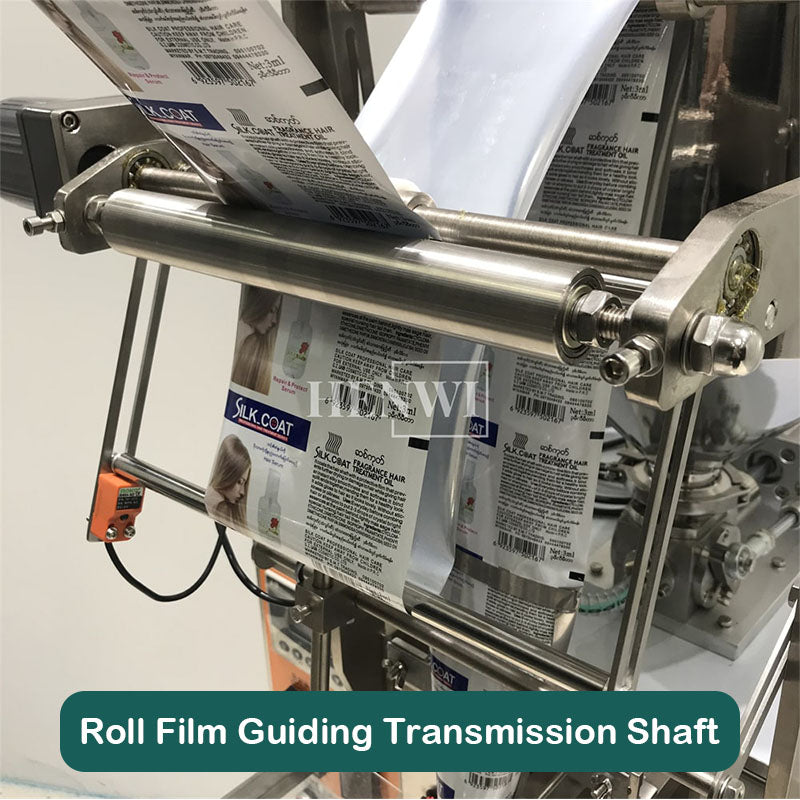

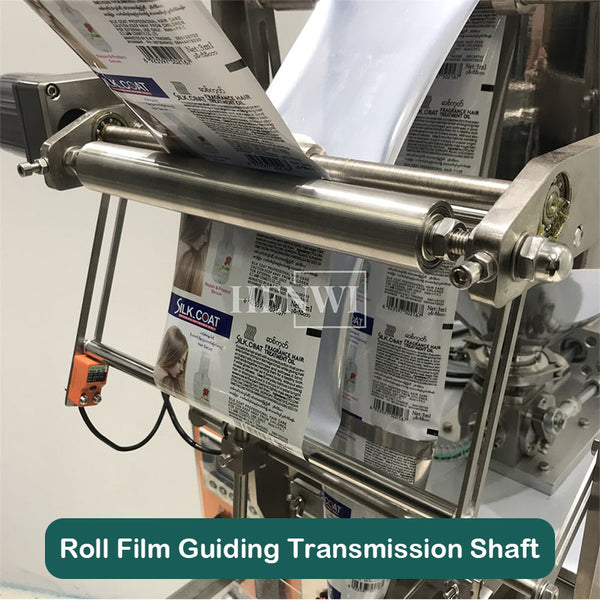

4. Film Guide Device

The film guide device directs and corrects the position and orientation of the film as it enters the machine. It ensures that the film is smoothly delivered into the pull system without deviation or folding, thus securing the precision of sealing and cutting operations.

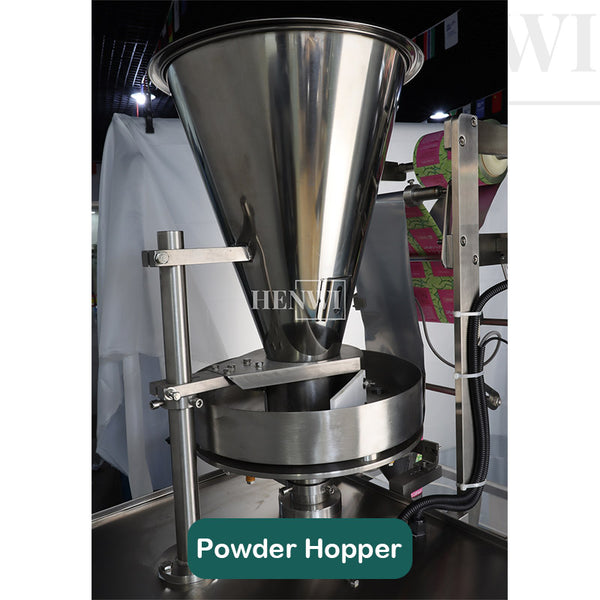

5. Rotary Dosing Device

The rotary dosing device is designed for accurate powder dosing, distributing the material evenly into each pouch. It ensures consistent fill volumes across all pouches, preventing issues caused by dosage deviations and enhancing the accuracy and quality of packaging.

6. Mold Heating and Four-Side Sealing with Date Coding Capability

The mold heating and four-side sealing unit heat seals and shapes the pouch edges, ensuring a secure and aesthetically pleasing seal. Adjustable heating accommodates various film materials, and the optional date coding function prints production dates or batch numbers on the seal for product traceability and management.

7. Bag Pull Device

The bag pull device moves the film forward during packaging, positioning each pouch correctly for filling and sealing. It typically operates with a servo motor, allowing precise control over pulling distance to ensure consistent pouch alignment and integrity.

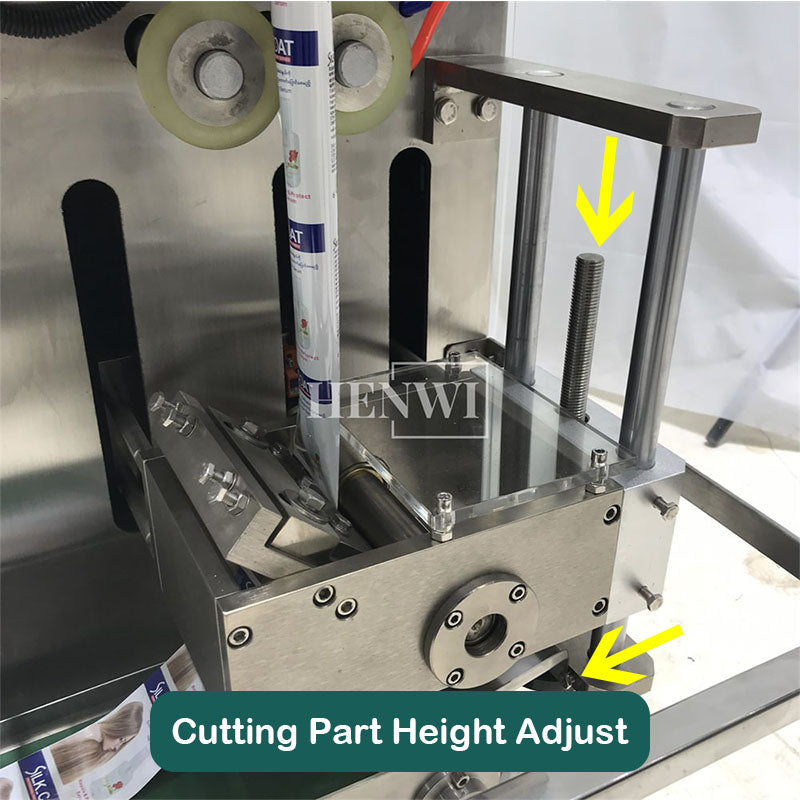

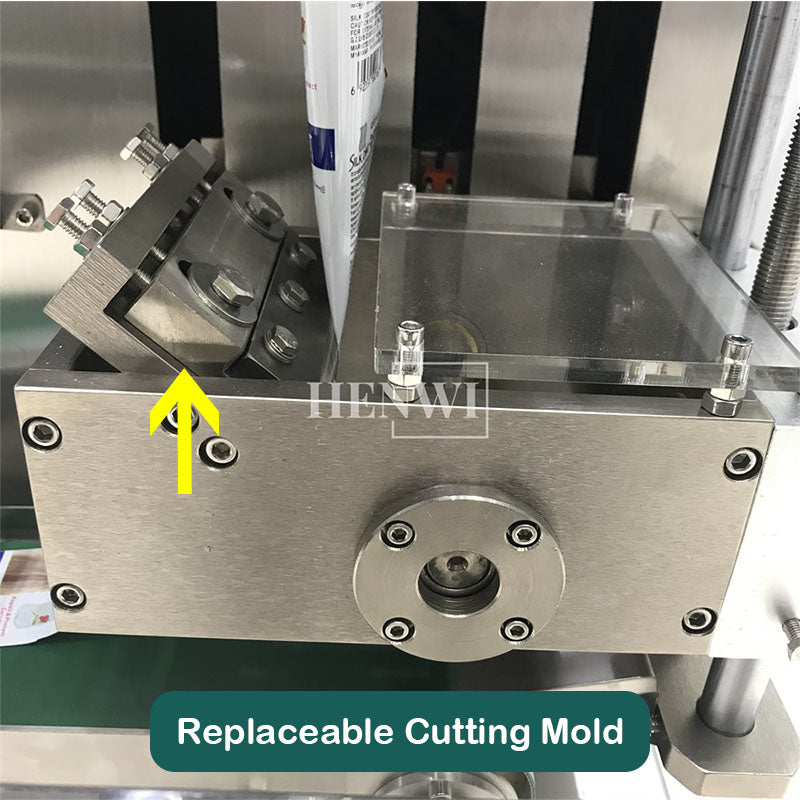

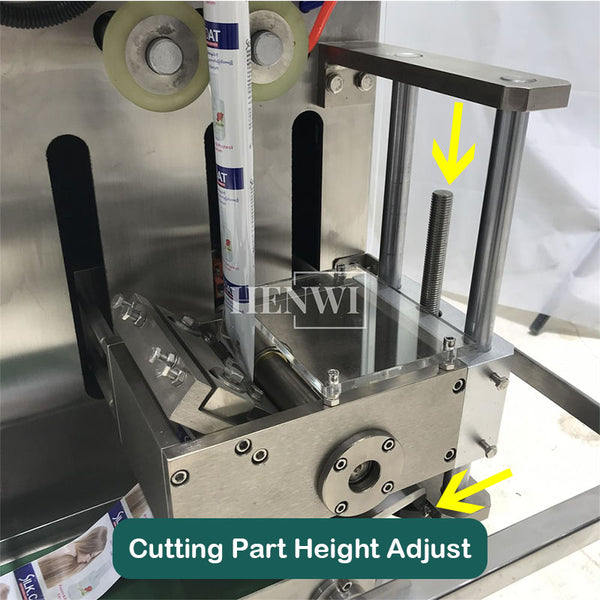

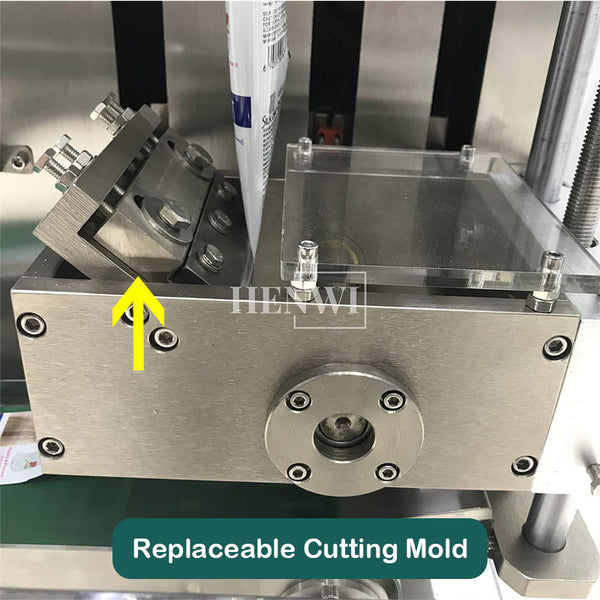

8. Bag Cutting Device

The bag cutting device separates each pouch after sealing, cutting them to the set length. The sharp, stable cutting tool ensures clean and smooth edges on each pouch, with no rough or irregular edges, enhancing the pouch’s appearance and user experience.

9. Touchscreen Operation

The touchscreen interface provides a user-friendly control panel, allowing operators to set packaging parameters, monitor machine status, adjust sealing temperature, and configure fill volume. The intuitive design simplifies operation and supports multiple languages for easy operator accessibility.

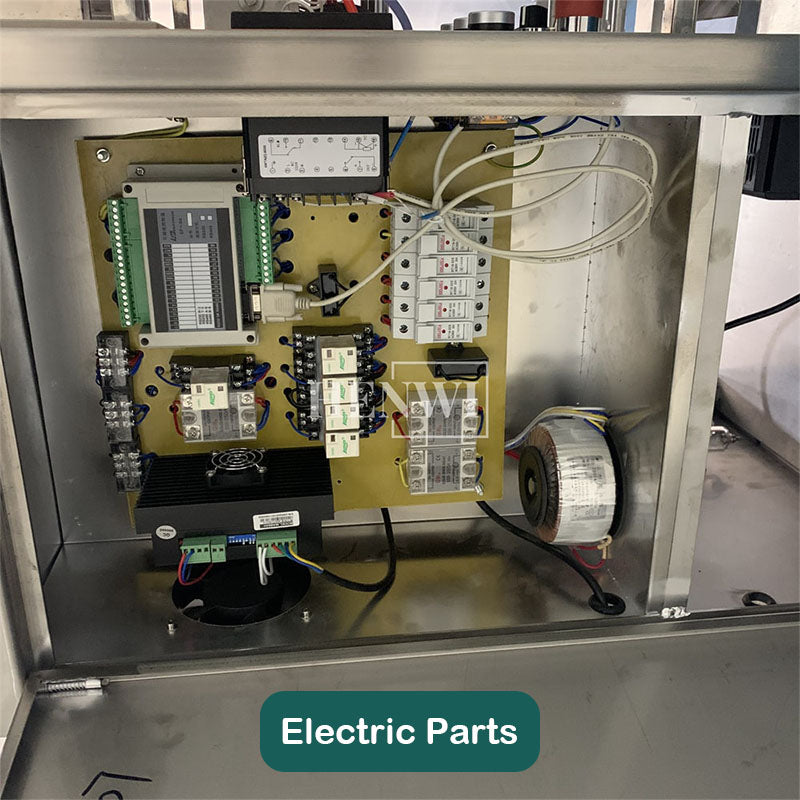

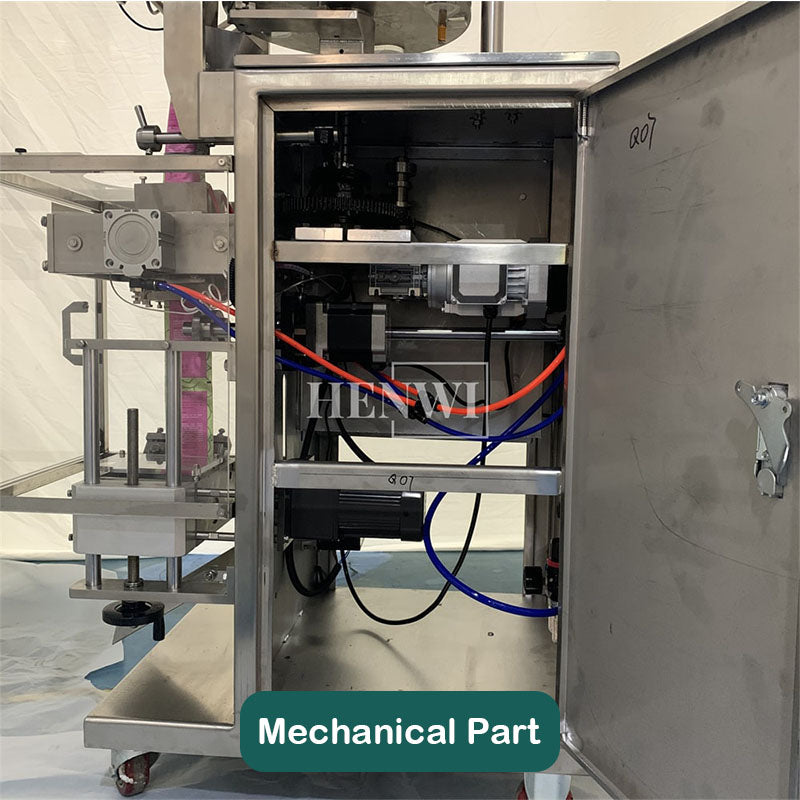

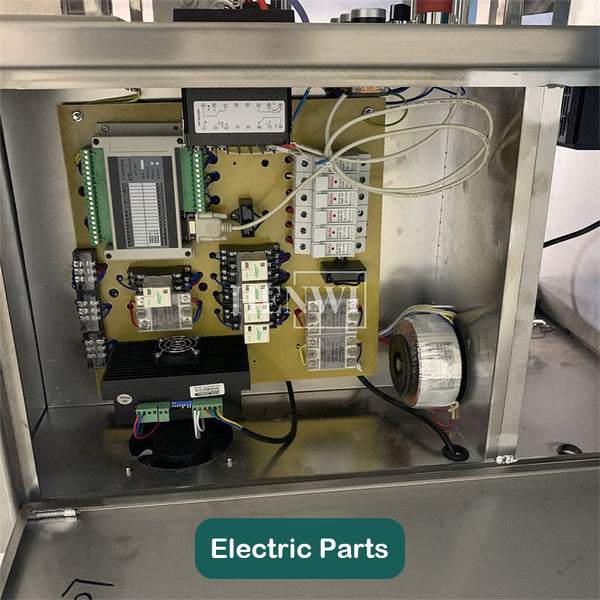

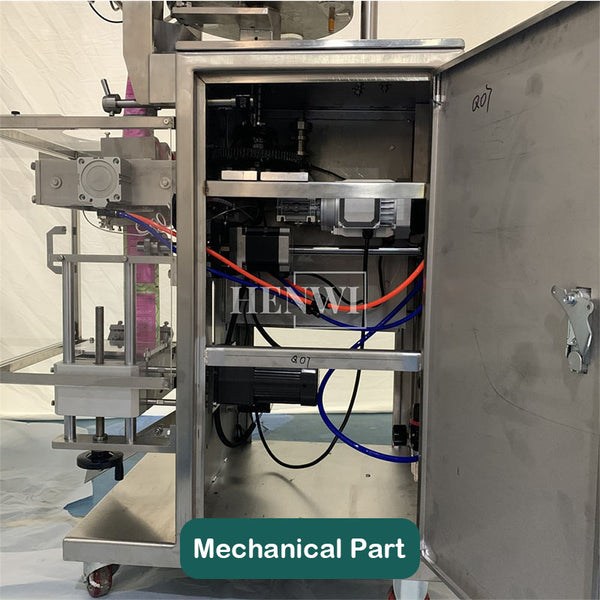

10. Electrical Control Box

The electrical control box houses the machine’s power control and signal processing components, integrating various electrical elements and control circuits. Managed by a PLC system, it ensures safe, stable, and efficient machine operation, with protective measures to maintain electrical system reliability and safety across different working conditions.

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.