Semi-automatic horizontal filling machine

- 価格

- $440

The semi-automatic pneumatic horizontal liquid filling machine is an innovative filling solution designed for a variety of liquid products, particularly suitable for industries such as food, pharmaceuticals, cosmetics, and chemicals. This machine offers reliable performance, high accuracy, and user-friendly operation, making it ideal for medium to high-volume production needs.

#### Key Features

1. **Pneumatic Filling Mechanism**:

- The machine utilizes a pneumatic filling system that ensures consistent and accurate liquid dispensing. The pneumatic operation reduces the mechanical complexity of the machine, leading to improved reliability and lower maintenance requirements.

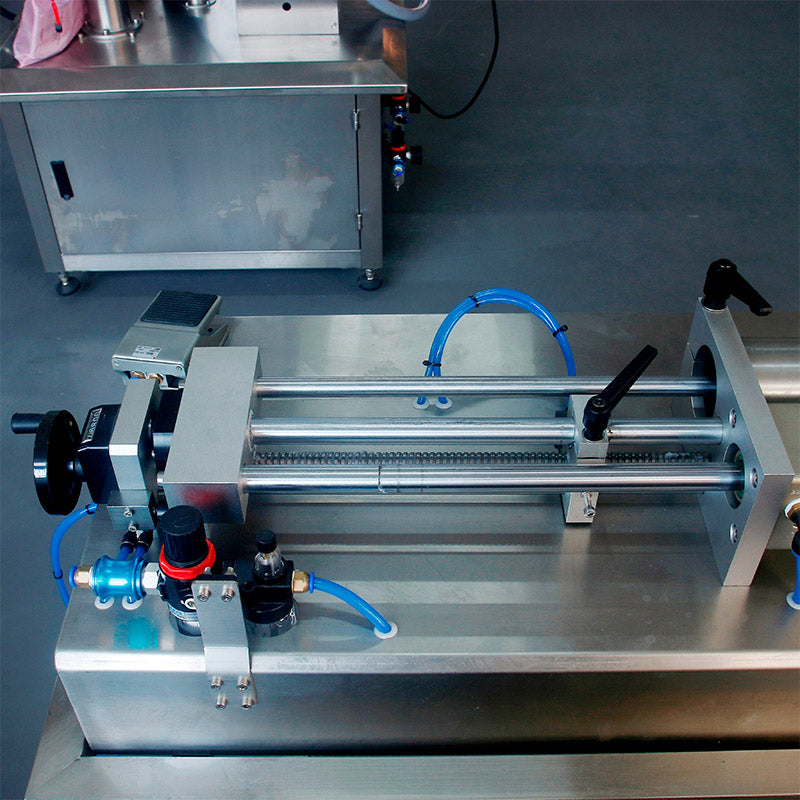

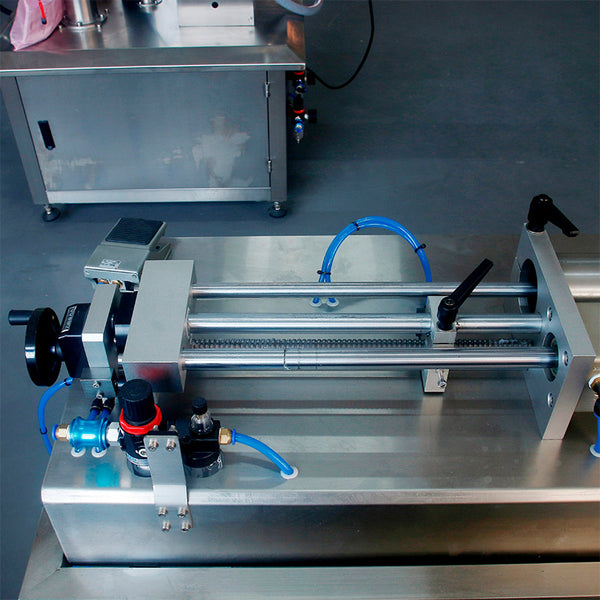

2. **Horizontal Design**:

- The horizontal configuration allows for efficient use of floor space and easier access for operators during loading and unloading. This design is especially beneficial for filling larger containers and facilitates a streamlined workflow in production environments.

3. **Adjustable Filling Volume**:

- The filling volume can be easily adjusted to accommodate different container sizes and product specifications. This flexibility allows operators to fill a wide range of liquid products, from small bottles to larger containers, with precision.

4. **Simple Operation**:

- Equipped with a user-friendly control panel, the machine allows operators to set filling parameters quickly and easily. The intuitive design minimizes training time and enhances overall operational efficiency.

5. **High Filling Accuracy**:

- The machine features advanced control systems that ensure high filling accuracy, typically within ±1% of the set volume. This precision is crucial for applications where exact dosages are necessary, such as in pharmaceuticals and specialty food products.

6. **Durable Construction**:

- Built with high-quality materials, including stainless steel and corrosion-resistant components, the machine is designed for durability and longevity. This robust construction ensures reliable performance even in demanding production environments.

7. **Hygienic Design**:

- All parts that come into contact with the liquid are constructed from food-grade materials, adhering to strict hygiene standards. The machine's design also facilitates easy cleaning and maintenance, ensuring compliance with industry regulations.

Application

#### 1. **Food Industry**

- **Sauces and Condiments**: Perfect for filling ketchup, mustard, mayonnaise, and other sauces that may have a thicker consistency.

- **Dressings**: Ideal for salad dressings and marinades that require accurate dispensing to maintain flavor profiles.

- **Dairy Products**: Suitable for filling yogurt, cream, and liquid cheese products.

#### 2. **Pharmaceutical Industry**

- **Ointments and Creams**: Designed for filling topical creams, gels, and ointments, ensuring precise dosage and consistency.

- **Liquid Medicines**: Effective for dispensing syrups and other oral medications, where accuracy in filling is critical.

- **Biological Products**: Used for filling various biological reagents and solutions, maintaining strict hygiene and safety standards.

#### 3. **Cosmetic Industry**

- **Lotions and Creams**: Ideal for filling facial creams, body lotions, and moisturizers with varying viscosities.

- **Serums**: Perfect for high-value cosmetic serums that require precise filling to prevent wastage.

- **Hair Products**: Suitable for filling shampoos, conditioners, and other hair care liquids.

#### 4. **Chemical Industry**

- **Industrial Chemicals**: Effective for filling various liquid chemicals, including lubricants and solvents, where precision and safety are crucial.

- **Cleaning Products**: Ideal for dispensing cleaning solutions, detergents, and other household chemicals.

#### 5. **Personal Care Products**

- **Toiletries**: Used for filling products such as shower gels, hand sanitizers, and liquid soaps.

- **Essential Oils**: Ideal for dispensing essential oils and fragrances, ensuring exact quantities for consumer packaging.

#### 6. **Household Products**

- **Pastes and Gels**: Suitable for filling products like adhesives, sealants, and gel-based household items.

- **Liquid Detergents**: Ideal for dispensing liquid laundry and dishwashing detergents with varying viscosities.

Parameter

| Number of filling heads: 1 |

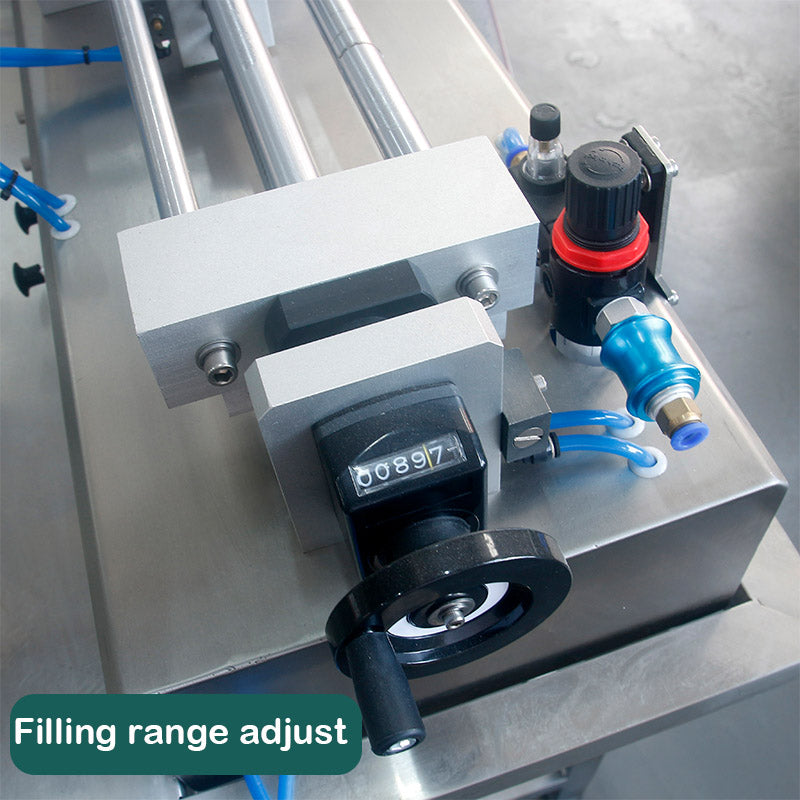

| Filling range: A.50-500ml; B.100-1000ml; C.300-3000ml; D.500-5000ml |

| Filling speed: 600-1800 bottles/hour |

| Measuring accuracy: ±1% |

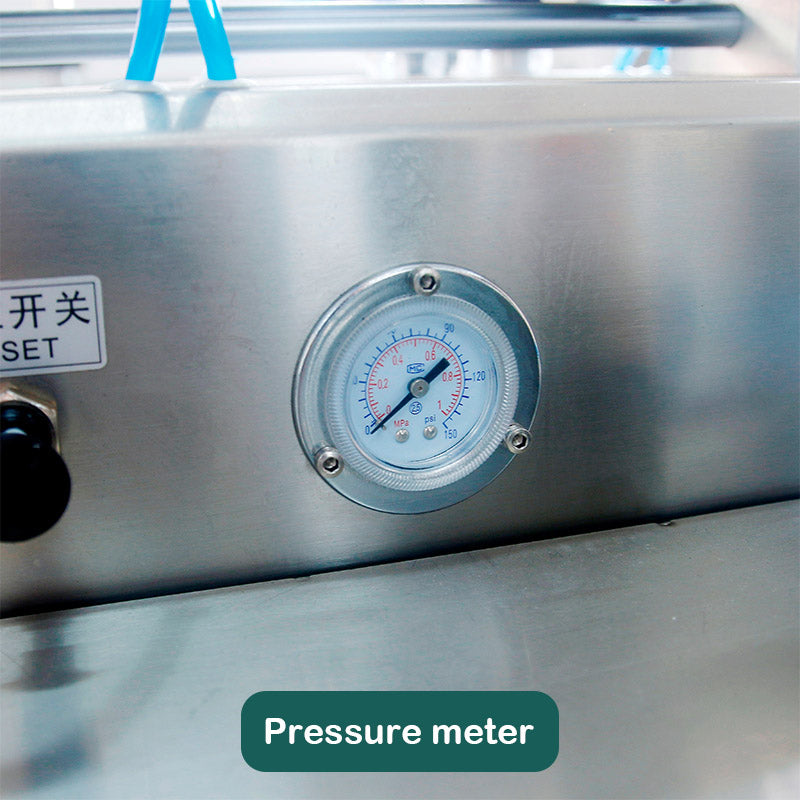

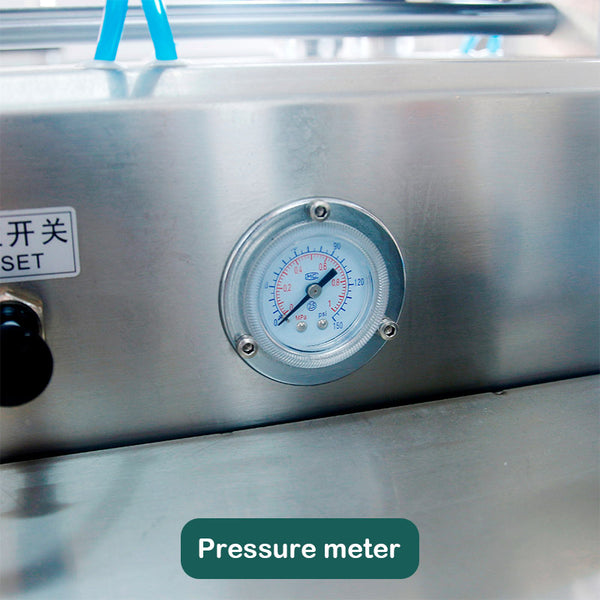

| Working air pressure: 0.6-0.7Mpa |

| Filling nozzle: Anti-drip |

| Machine size: 1100*350*500mm |

| Machine weight: 50kgs |

Filling Nozzle

The filling nozzle is equipped with an anti-drip or anti-residue design to ensure that liquid residue is minimized during the filling process, reduce material waste and keep the production line clean.

The filling nozzle is equipped with an anti-drip or anti-residue design to ensure that liquid residue is minimized during the filling process, reduce material waste and keep the production line clean.

The filling nozzle can be adjusted according to the size of different containers and material viscosity to adapt to various types of bottles or materials to meet production needs.

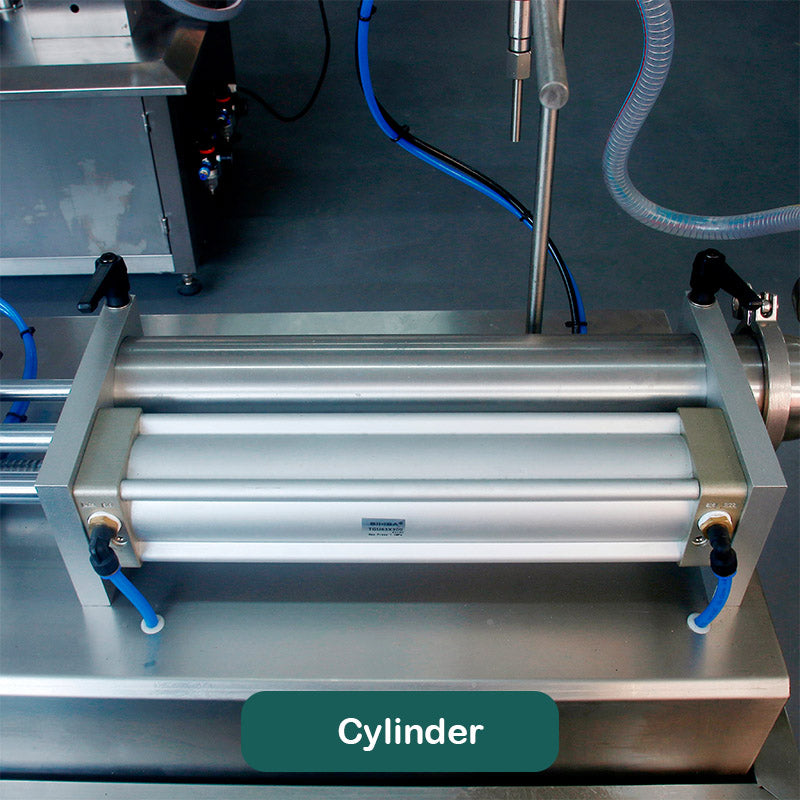

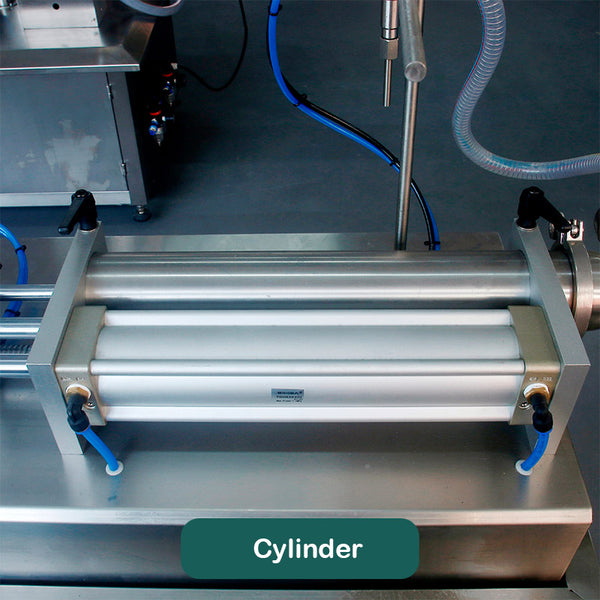

Piston & Cylinder

One is air cylinder, the air push cylinder is driven by air pressure to push the liquid from the hopper or material cylinder to the filling nozzle to ensure a smooth filling process. By adjusting the stroke and pressure of the cylinder, the amount of liquid filled each time can be accurately controlled to ensure filling consistency.

Another one is material cylinder, the cylinder is used to store the liquid to be filled to ensure the continuity of the filling process. Through the action of the piston, the cylinder can generate pressure to push the liquid to the filling nozzle to achieve efficient filling.

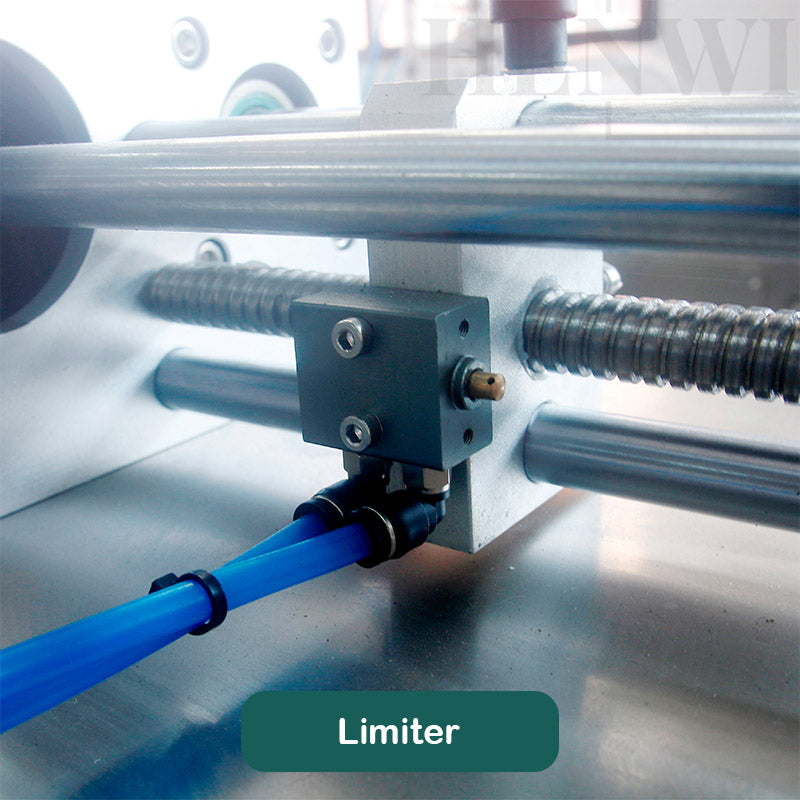

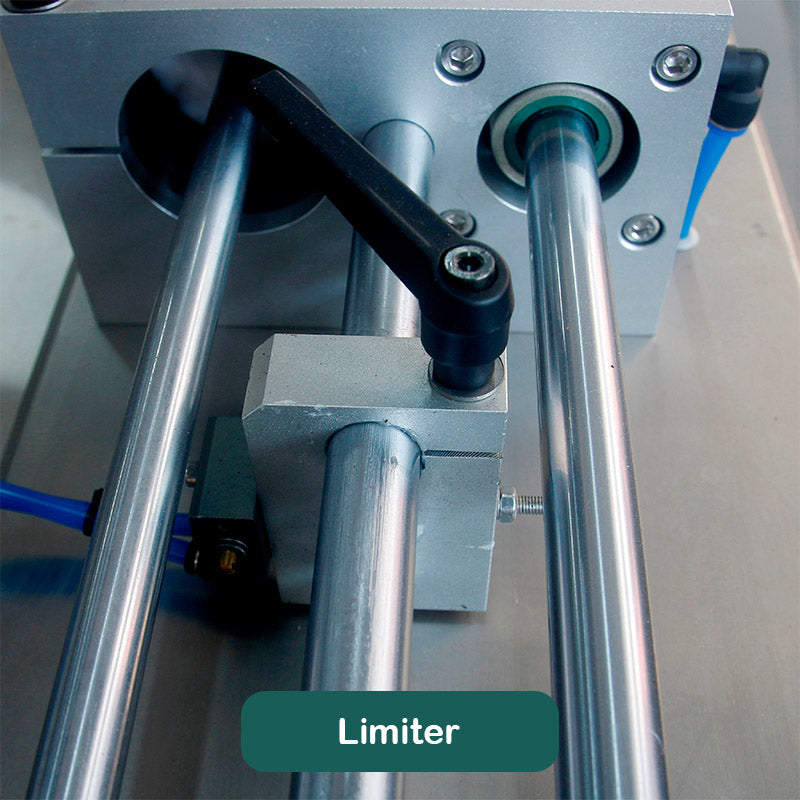

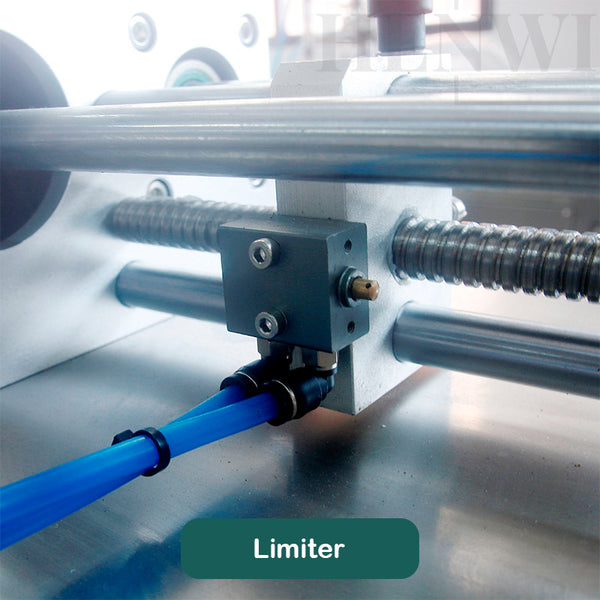

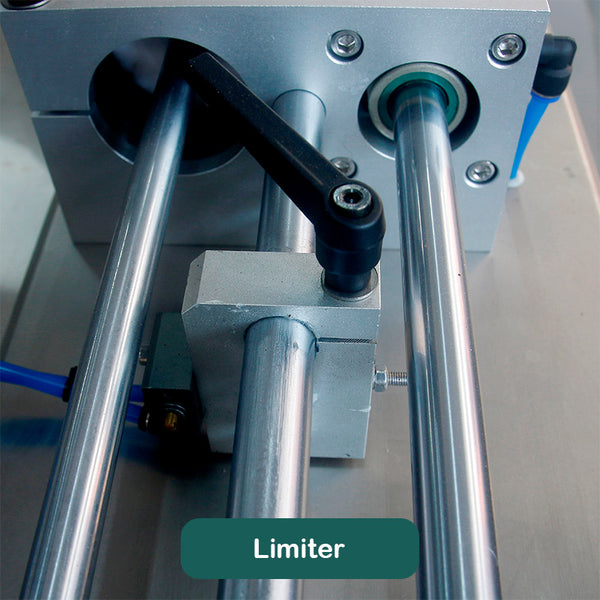

Stroke limit switch

3-way Valve

The three-way valve can direct liquid or paste materials to different channels or positions. It has three interfaces and can switch between two flow directions to transport materials from the hopper to the filling head, or from the storage tank to the filling head.

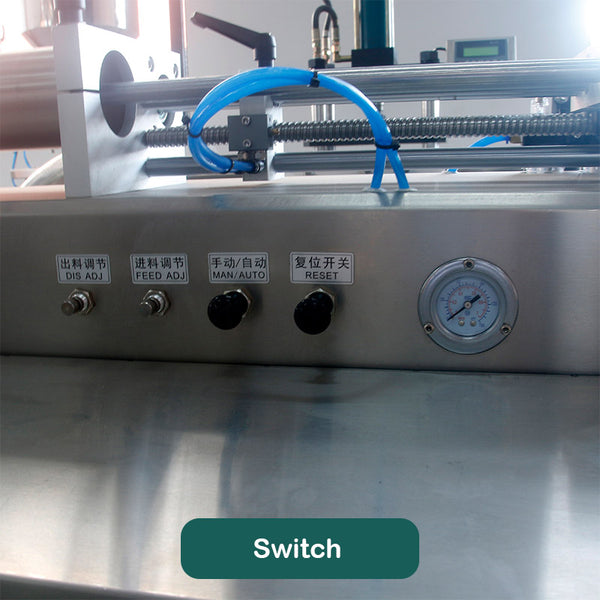

Control Panel

The air pressure gauge displays the air pressure level in the pneumatic system in real time, helping the operator monitor the working status of the system. Ensure that the air pressure is within the set range to avoid equipment failure or inaccurate filling caused by excessive or low air pressure.

Button control allows the operator to easily start and stop the filling process. Through simple key operation, the basic functions of the filling machine can be operated, reducing the complexity of manual operation.

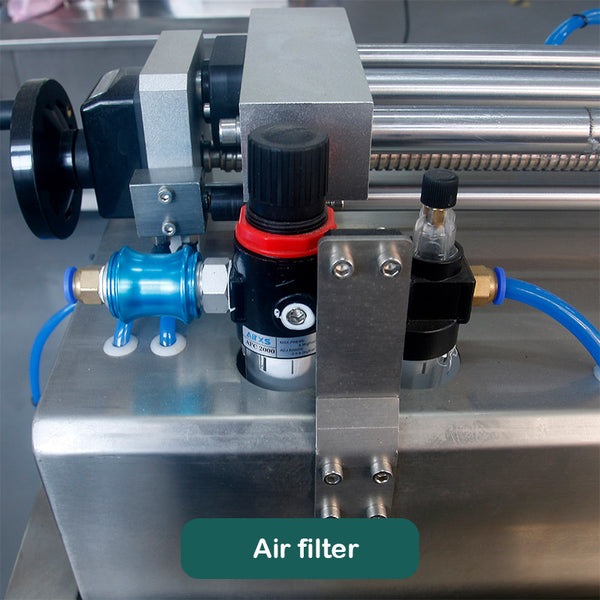

Air pressure adjustor

The compressed air intake valve is mainly used to filter water, oil, dust and other impurities in the compressed air to ensure the accuracy and stability of the pneumatic components in the machine and extend the life of the pneumatic components.

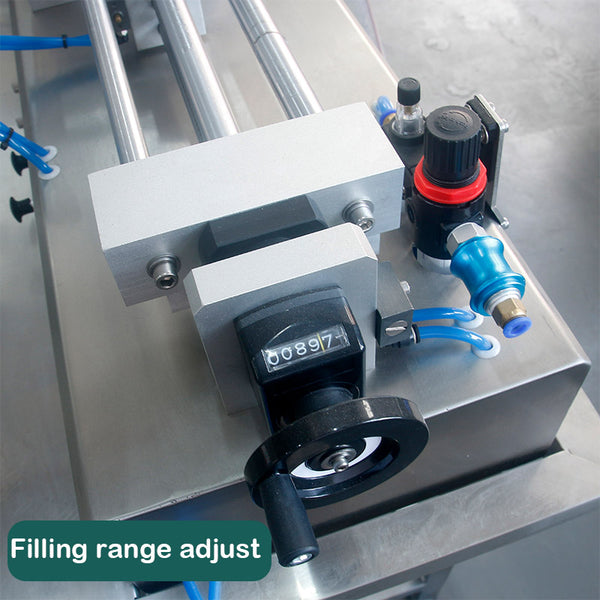

Filling range adjustor

In production, you may need to process containers of different sizes and specifications. The filling volume adjustment hand wheel provides flexibility, allowing the operator to quickly adjust the filling volume according to the container capacity and production needs to adapt to different production tasks.

Foot switch

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.