Semi-automatic ceramic pump small volume filling machine

- 価格

- $980

The semi-automatic micro ceramic pump filling machine is a highly precise filling device designed specifically for small-dose liquid products. It is widely used in pharmaceutical, cosmetic, food, and chemical industries. This equipment is particularly suitable for filling high-value and sensitive liquids such as blood, biological reagents, oral solutions, injectables, high-end cosmetics, e-liquid, flavorings, and disinfectants. With a filling range of 0.2 to 5 milliliters, it incorporates advanced ceramic pump technology and a touch screen control system, ensuring an efficient and accurate filling process.

#### Key Features

1. **Micro Ceramic Pump Technology**

- **High Precision Filling**: The ceramic pump is specifically designed for micro filling, achieving accurate filling within the range of 0.2 to 5 milliliters. It ensures consistency and repeatability in each filling cycle, making it ideal for applications requiring high filling accuracy.

- **Corrosion and Wear Resistance**: Ceramic materials provide excellent resistance to corrosion and wear, making the machine suitable for a wide range of chemical liquids, ensuring stability and reliability during prolonged use.

- **Low Pulsation Flow**: The design of the micro pump guarantees low pulsation liquid delivery, providing a smooth filling flow that enhances overall filling quality.

2. **User-Friendly Touch Screen Control**

- **Intuitive Operating Interface**: Equipped with a 7-inch or larger touch screen, operators can easily set and monitor filling parameters, including filling volume, speed, and filling mode (manual or automatic), with real-time data display for ease of operation and adjustment.

- **Programmable Control**: Multiple filling parameter sets can be stored, allowing users to quickly switch between different products, thereby improving production efficiency.

3. **Adjustable Filling Nozzle**

- **Versatile Adaptability**: The filling nozzle's height and diameter can be adjusted to accommodate different container specifications, ensuring precise alignment during the filling process.

- **Anti-Drip Design**: Features an efficient anti-drip system that minimizes product waste and maintains a clean working environment.

4. **Compact Design**

- **Space-Saving**: The equipment has a compact design, suitable for production environments with limited space, allowing for easy integration into existing production lines and reducing layout complexity.

5. **Hygienic Design**

- **Compliance with Hygiene Standards**: All components in contact with the product are made of materials that comply with GMP (Good Manufacturing Practice) and FDA standards, such as 304 or 316L stainless steel and ceramics, facilitating easy cleaning and sterilization to ensure product safety.

Parameter

| Number of filling heads: 1 |

| Suggest filling range: 0.2-5ml |

| Max filling range: 100-750ml |

| Filling speed: 1800-3000 bottles/hour |

| Measuring accuracy: ±1% |

| Power: 120W |

| Voltage: 110V/220V |

| Pump: Ceramic pump |

| Pump speed: 0-500PRM |

| Output range per rotate:0.2-2.8ml |

| Working air pressure: 0.6-0.7Mpa |

| Filling nozzle: 2mm diameter, anti-drip |

| Memory: Yes |

| Machine size: 225*450*300mm |

| Machine weight: 10kgs |

| Touch screen: COOLMAY |

The PLC touchscreen is a crucial control component of the automatic servo piston filling machine, providing an intelligent and user-friendly operating experience.

1. **Intuitive User Interface**: The touchscreen features a color display with a user-friendly interface, allowing operators to easily set and adjust various parameters such as filling volume, filling speed, and servo motor operating modes through simple taps and swipes.

2. **Parameter Setting and Adjustment**: The touchscreen enables precise setting of filling parameters, including the filling volume per cycle, filling time, and speed.

3. **Real-Time Monitoring and Display**: The operational status of the machine is displayed in real-time on the touchscreen, including current filling speed, filling volume, production batch information, and equipment faults, making it convenient for operators to monitor machine performance.

4. **Fault Diagnosis Function**: The touchscreen features self-diagnosis and alarm capabilities. If a fault occurs, the system automatically displays alarm information and the cause of the issue, helping operators quickly identify and resolve problems, thus minimizing downtime.

5. **Data Storage and Recall**: The touchscreen has storage functions that allow different filling parameter settings to be saved. This facilitates quick retrieval of pre-set parameters when switching between products, improving efficiency and reducing the need for repetitive setups.

6. **Multi-Language Support**: Typically, the touchscreen supports multiple language settings, allowing operators to choose the appropriate language, enhancing ease of use and accuracy in operations.

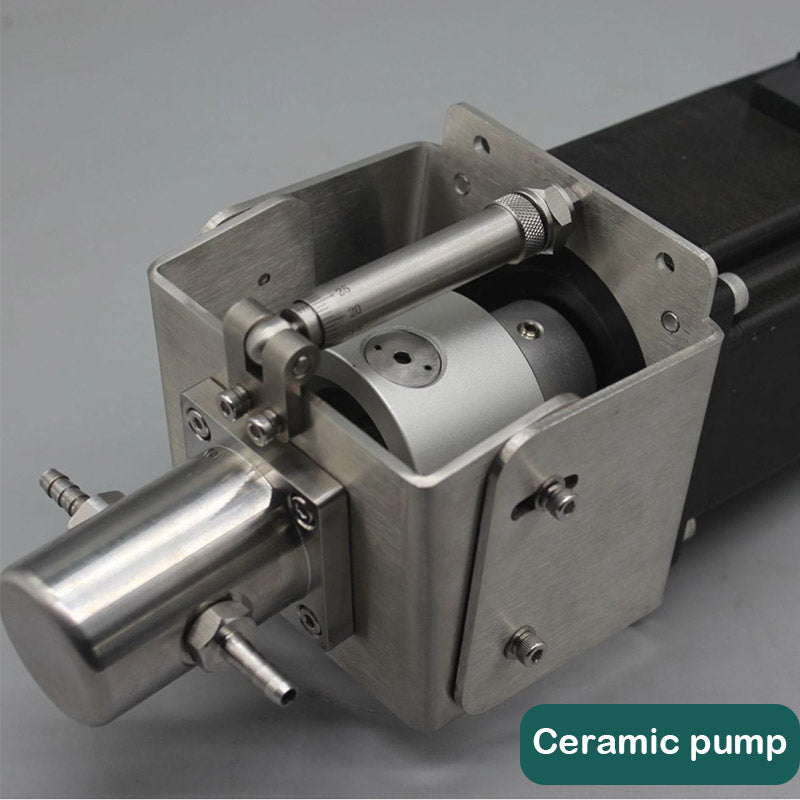

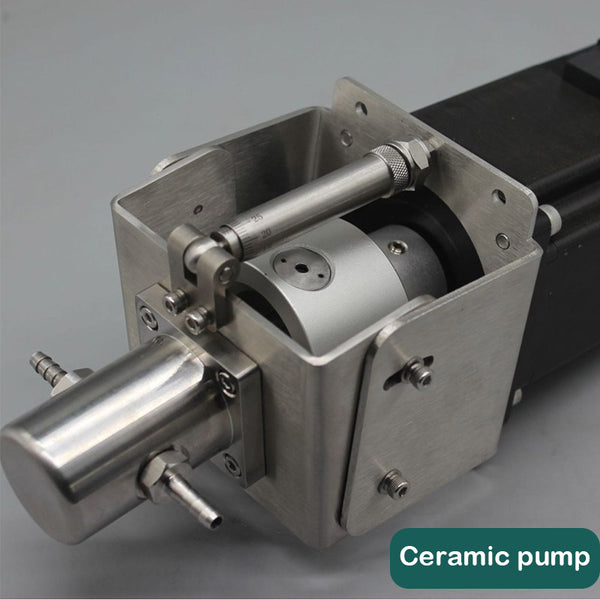

The ceramic pump is a key component of the semi-automatic micro ceramic pump filling machine, designed for precision and efficiency in filling small quantities of liquid.

1. **High Precision and Accuracy**:

- The ceramic pump is engineered specifically for micro-filling applications, allowing for precise dispensing of liquid volumes ranging from 0.2 to 5 milliliters. Its design ensures minimal variation in fill volumes, making it ideal for high-accuracy requirements.

2. **Corrosion and Chemical Resistance**:

- Made from high-quality ceramic materials, the pump exhibits exceptional resistance to corrosion and chemical wear. This property enables it to handle a wide range of aggressive liquids, including solvents, acids, and biological reagents, without degradation or contamination.

3. **Low Pulsation Flow**:

- The pump design provides a smooth and consistent flow with minimal pulsation. This characteristic is crucial for applications where uniformity in filling is necessary, such as in pharmaceutical and cosmetic industries.

4. **Self-Priming Capability**:

- The ceramic pump features a self-priming mechanism, allowing it to efficiently draw liquid from the storage tank into the pump chamber without manual intervention. This capability enhances operational efficiency and reduces the risk of air pockets in the system.

5. **Hygienic Design**:

- The construction of the ceramic pump adheres to strict hygiene standards, making it suitable for applications involving sensitive liquids such as pharmaceuticals, cosmetics, and food products. The smooth surfaces and easy-to-clean design minimize the risk of contamination.

ocesses.

1. **Advanced Anti-Drip Design**:

- The filling nozzle incorporates a specialized anti-drip mechanism that prevents residual liquid from leaking after the filling process. This design minimizes product waste and ensures a clean working environment, which is especially important for high-value liquids.

2. **Durable Construction**:

- Constructed from high-quality materials stainless steel and food-grade plastics, the anti-drip filling nozzle is resistant to corrosion and wear. This durability ensures a long service life, even when handling aggressive or viscous liquids.

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.