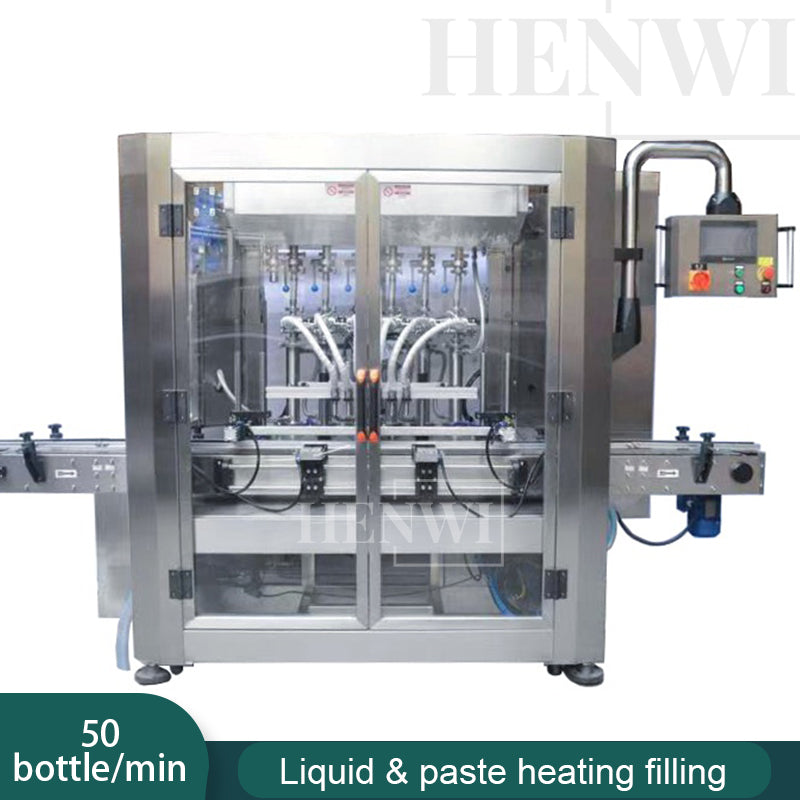

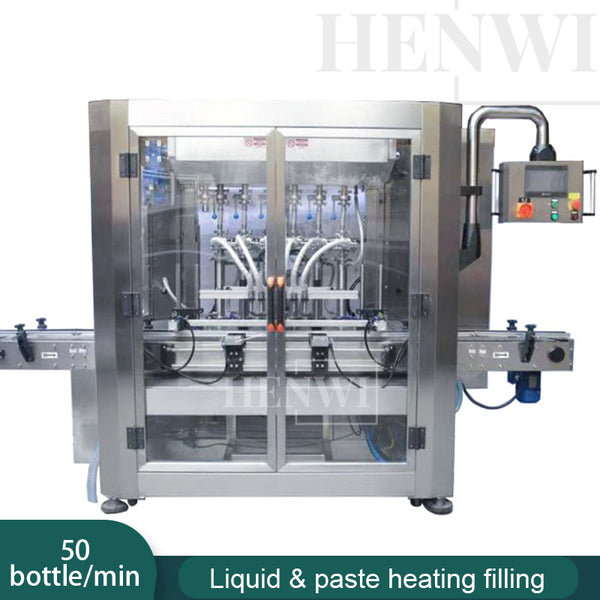

Henwi Automatic Heating 6 Piston Paste Liquid Filling Machine

- Prezzo

- $12,200

The automatic constant temperature servo piston filling machine is a highly advanced filling system designed for precise and consistent dispensing of various liquids, pastes, and high-viscosity materials. It is widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. Below are the key features, functionalities, and advantages of this machine.

#### 1. **Working Principle**

- **Servo Motor Control**: The machine employs a servo motor that drives the piston, enabling precise control over the filling volume and speed. The servo system allows for quick adjustments and high accuracy during the filling process.

- **Constant Temperature Regulation**: Integrated heating or cooling systems maintain a constant temperature for the material being filled, which is crucial for products that are sensitive to temperature fluctuations (e.g., certain sauces, creams, or viscous liquids).

#### 2. **Key Features**

- **High Precision Filling**: The servo piston design ensures that the filling volume is accurate, with typical tolerances within ±0.3% to ±0.5%. The adjustable stroke length and speed settings allow for customization based on the specific requirements of different products.

- **Temperature Control System**: The machine is equipped with an advanced temperature control system that includes sensors and heating/cooling elements to maintain the desired temperature range during the filling process. This feature is essential for preventing product degradation and ensuring quality.

- **User-Friendly Interface**: The machine is equipped with a PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) that allow operators to easily set and monitor filling parameters, including temperature, filling volume, and speed.

#### 3. **Design Characteristics**

- **Hygienic Construction**: Made from high-quality stainless steel 304, the machine is designed for easy cleaning and maintenance, complying with food safety and pharmaceutical regulations.

- **Modular Components**: The machine design features modular components that facilitate easy assembly, disassembly, and maintenance. This modularity allows for quick repairs and part replacements.

#### 4. **Performance Advantages**

- **Versatile Application**: The machine can handle a wide range of materials, including low to high-viscosity liquids, pastes, creams, and products with particulates. This versatility makes it suitable for various industries.

- **Consistent Product Quality**: The constant temperature feature ensures that the physical and chemical properties of the material remain stable throughout the filling process, leading to consistent product quality.

#### 5. **Safety and Maintenance Features**

- **Safety Mechanisms**: The machine includes safety features such as emergency stop buttons, overload protection, and alarm systems for detecting malfunctions or abnormal conditions.

- **Easy Maintenance**: The design includes easy-access panels and components for cleaning and maintenance, reducing downtime and ensuring that the machine operates efficiently.

Application

- **Food and Beverage**: Ideal for filling sauces, dressings, dairy products, and beverages that require precise temperature control.

- **Pharmaceuticals**: Suitable for filling creams, gels, and other products that need to be maintained at specific temperatures to preserve their efficacy.

- **Cosmetics**: Used for dispensing lotions, creams, and other cosmetic products that require temperature regulation during filling.

- **Chemicals**: Effective for handling industrial liquids and pastes that are sensitive to temperature changes.

Parameter

| Number of filling heads: 6 |

| Filling range: A.100-1000ml; B.300-3000ml; C.500-5000ml; |

| Filling speed: 1800-3000 bottles/hour |

| Measuring accuracy: ±0.5% |

| Power: 7KW |

| Voltage: 380V |

| Working air pressure: 0.6-0.7Mpa |

| Air consumption: 4-6m³/min |

| Machine size: 4000*1300*2100mm |

| Machine weight: 700kgs |

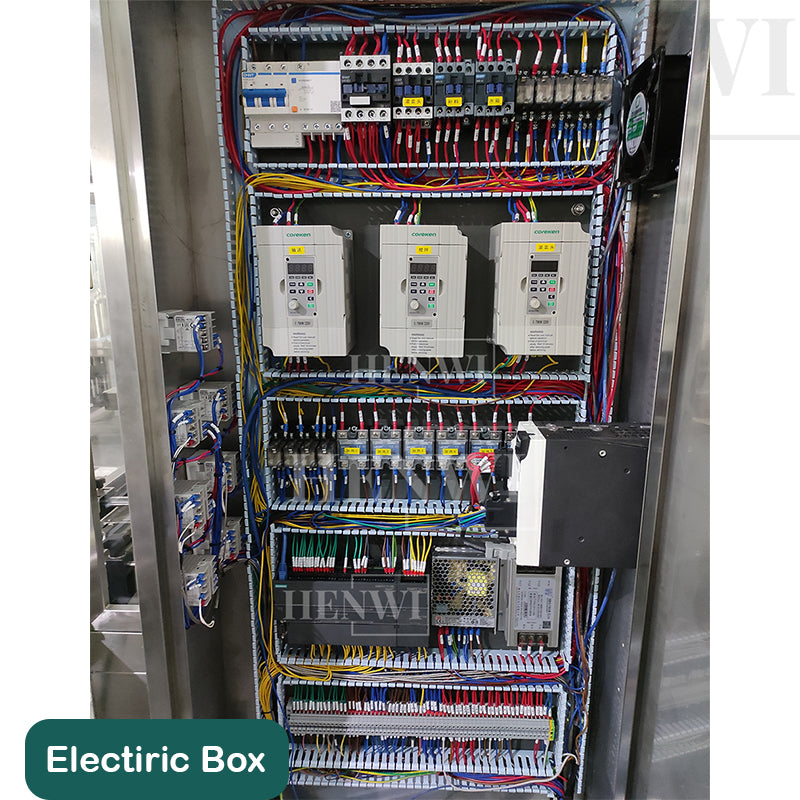

| PLC: Mitsubishi |

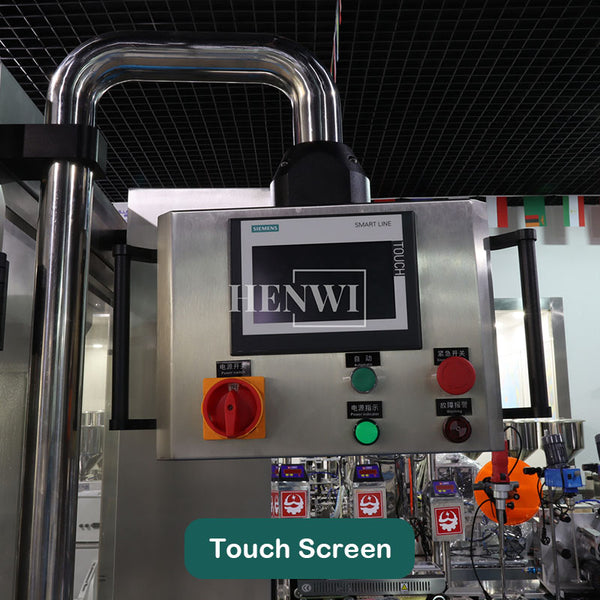

| Touch screen: Simens |

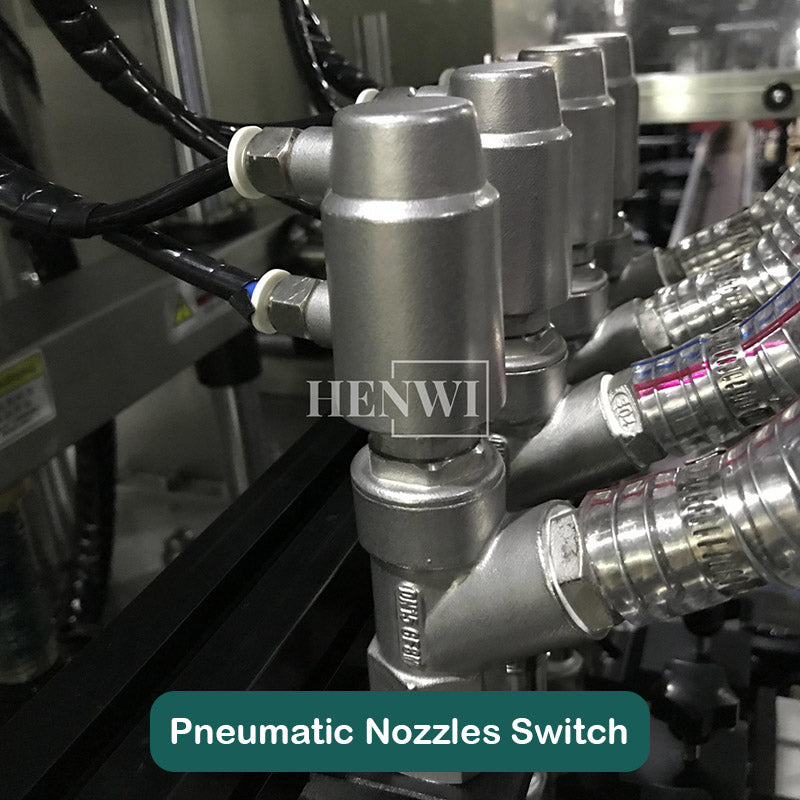

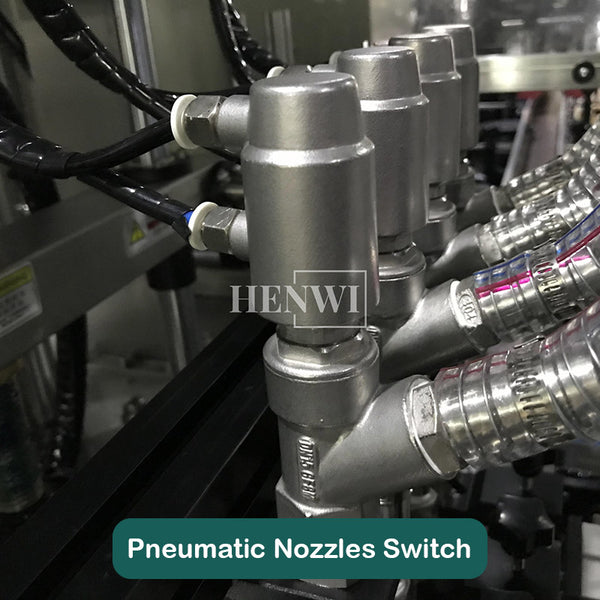

| Pneumatic components: AirTac Taiwan |

| Sensor: KEYENCE |

| Servo system: TECO,China |

| Motors: ZD,China |

| Relay: Schneider, France |

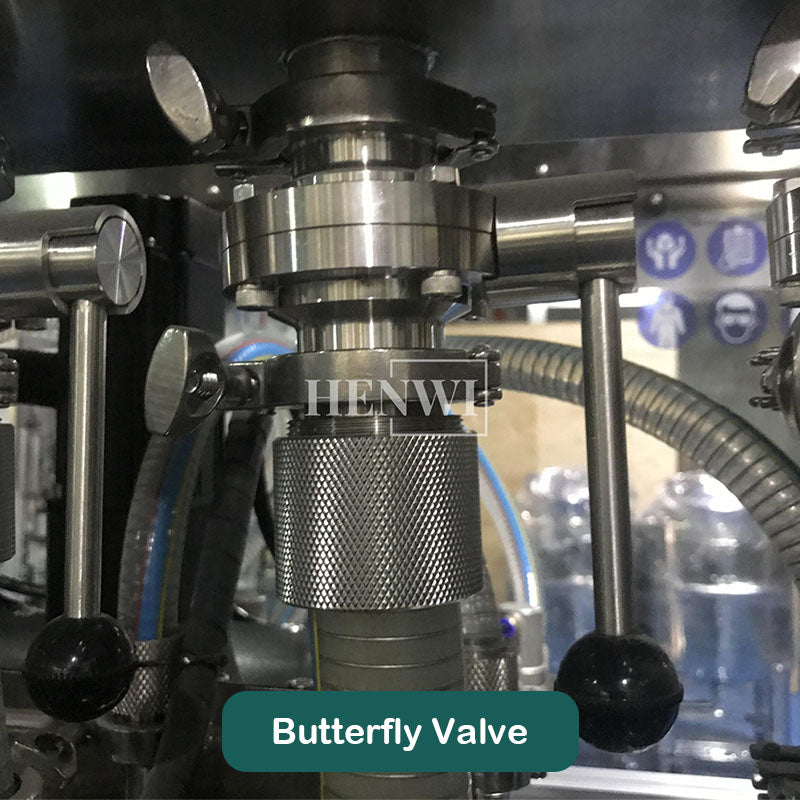

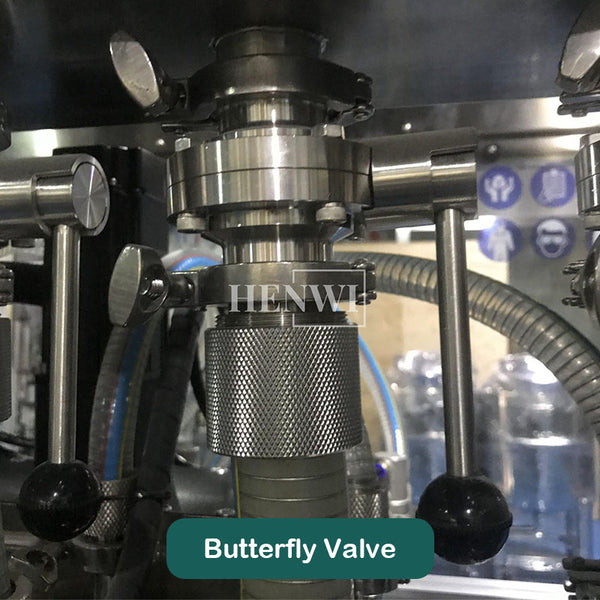

Constant Temperature Anti-Drip Filling Nozzle

The constant temperature anti-drip filling nozzle is a specialized component of the automatic constant temperature servo piston filling machine. This nozzle plays a crucial role in ensuring the precise and clean dispensing of various materials, especially those that are temperature-sensitive or prone to dripping.

#### 1. **Design and Construction**

- **High-Quality Materials**: The filling nozzle is constructed from high-grade stainless steel 316L to ensure durability, corrosion resistance, and compliance with hygiene standards. This material is essential for industries like food and pharmaceuticals.

- **Thermal Insulation**: The nozzle is designed with thermal insulation properties to maintain a constant temperature during the filling process. This is particularly important for products that can change viscosity or quality with temperature fluctuations.

#### 2. **Functionality**

- **Accurate Dispensing**: The nozzle is engineered to provide high accuracy in filling volumes, ensuring that the specified amount of product is dispensed into each container. The design allows for fine adjustments to the flow rate based on product viscosity and other characteristics.

- **Anti-Drip Feature**: The nozzle is equipped with an anti-drip mechanism, which prevents residual material from dripping after the filling process is complete. This feature is critical for maintaining a clean working environment and reducing waste.

#### 3. **Performance Advantages**

- **Consistent Filling Quality**: The combination of constant temperature control and anti-drip design ensures that the material retains its intended properties and that the filling process is clean, leading to consistent product quality.

- **Reduced Product Waste**: By preventing drips and spills, the nozzle minimizes product waste, contributing to cost savings and improving overall efficiency in the production line.

#### 4. **Easy Maintenance and Cleaning**

- **Removable Design**: The nozzle is often designed for easy removal, facilitating quick cleaning and maintenance. This is particularly important in industries with stringent hygiene requirements.

- **Compatibility with CIP Systems**: The nozzle can be integrated with Clean-In-Place (CIP) systems, allowing for automatic cleaning without disassembly, ensuring that it remains sanitary and operationally efficient.

Filling nozzle automatic lifting device (cylinder)

Automatic telescopic receiving chute

PLC Touchscreen

The PLC touchscreen is a crucial control component of the automatic servo piston filling machine, providing an intelligent and user-friendly operating experience.

1. **Intuitive User Interface**: The touchscreen features a color display with a user-friendly interface, allowing operators to easily set and adjust various parameters such as filling volume, filling speed, and servo motor operating modes through simple taps and swipes.

2. **Parameter Setting and Adjustment**: The touchscreen enables precise setting of filling parameters, including the filling volume per cycle, filling time, and speed. Operators can quickly adjust these settings based on production needs, ensuring flexibility to handle different batches.

3. **Real-Time Monitoring and Display**: The operational status of the machine is displayed in real-time on the touchscreen, including current filling speed, filling volume, production batch information, and equipment faults, making it convenient for operators to monitor machine performance.

4. **Fault Diagnosis Function**: The touchscreen features self-diagnosis and alarm capabilities. If a fault occurs, the system automatically displays alarm information and the cause of the issue, helping operators quickly identify and resolve problems, thus minimizing downtime.

5. **Data Storage and Recall**: The touchscreen has storage functions that allow different filling parameter settings to be saved. This facilitates quick retrieval of pre-set parameters when switching between products, improving efficiency and reducing the need for repetitive setups.

6. **Multi-Language Support**: Typically, the touchscreen supports multiple language settings, allowing operators to choose the appropriate language, enhancing ease of use and accuracy in operations.

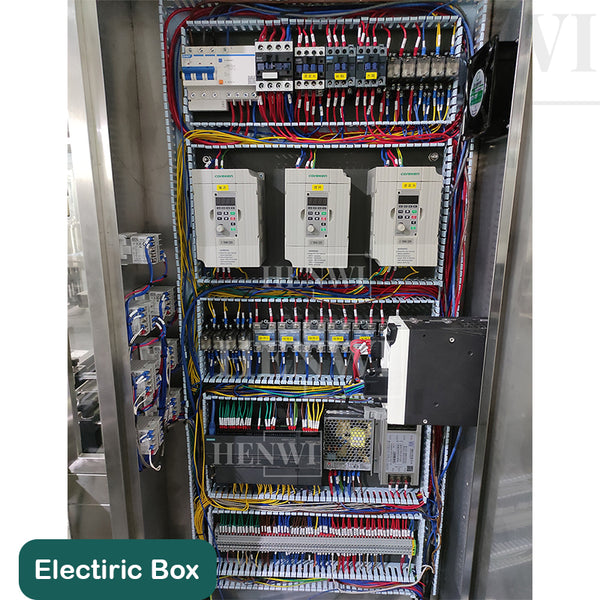

Electrical Box

The electrical system is the core control unit of the automatic filling machine, responsible for coordinating various electrical components and functional modules to achieve automated operations and precise control.

1. **PLC Control System**: The entire machine is controlled by a Programmable Logic Controller (PLC) as the central control unit. The PLC processes signals from sensors, actuators, and the human-machine interface (HMI) touchscreen, managing real-time control of detection, filling, conveying, and other operations.

2. **Servo Drive System**: The servo motor is critical for controlling filling precision and speed. The servo driver connects to the PLC, receiving signals and accurately controlling the motor's speed and position.

3. **Sensor System**: The electrical system is equipped with multiple sensors, such as liquid level sensors and position sensors, for real-time monitoring of the machine's status. Liquid level sensors manage material replenishment, while position sensors control the accurate movement of the filling head.

4. **Frequency Converter**: The frequency converter adjusts motor speed, especially when flexible control of filling or conveying speed is required. It ensures smooth speed regulation, protecting the motor and extending the machine's lifespan.

5. **Power Management System**: The machine includes a reliable power supply and protection system, effectively controlling startup and shutdown while preventing damage to electrical components from current overload or voltage fluctuations. The electrical cabinet houses air switches, overload protectors, and other safety devices to ensure operational safety.

6. **Emergency Stop System**: The machine is equipped with an emergency stop button. In case of an emergency, operators can press the button to immediately cut off all power, halting the machine and preventing accidents. This system enhances the machine's safety and reliability.

7. **Automatic Alarms and Fault Diagnosis**: The electrical system integrates automatic alarm and fault diagnosis functions. If an abnormality or malfunction occurs, the system alerts the operator via the touchscreen or an audible alarm, displaying detailed fault information to help quickly identify and address the issue, minimizing downtime.

PLC

Digital Display Temperature Meter

The digital display temperature meter is a vital component of the automatic constant temperature servo piston filling machine. It provides real-time monitoring and precise control of the temperature during the filling process, ensuring that materials maintain their desired properties.

#### 1. **Construction and Design**

- **High-Quality Display**: The temperature meter features a clear, high-contrast digital display that allows for easy reading of temperature values. The display is typically designed to be resistant to glare and moisture, ensuring visibility in various working conditions.

- **Durable Housing**: The meter is housed in a robust casing, often made from stainless steel or high-grade plastic, which protects it from environmental factors such as humidity, dust, and corrosive substances.

#### 2. **Functionality**

- **Real-Time Temperature Monitoring**: The digital temperature meter continuously monitors the temperature of the material being dispensed. This real-time feedback allows operators to ensure that the material is maintained within the specified temperature range, which is crucial for achieving consistent product quality.

- **Temperature Sensor Integration**: The meter is equipped with a high-accuracy temperature sensor, often a thermocouple or RTD (Resistance Temperature Detector), which provides precise and rapid readings of temperature fluctuations.

#### 3. **Performance Advantages**

- **High Accuracy and Sensitivity**: The digital display temperature meter typically offers a high degree of accuracy, often within ±0.5°C. This precision is vital for materials that are sensitive to temperature changes, ensuring optimal filling conditions.

- **User-Friendly Interface**: Many models include intuitive controls that allow operators to set temperature thresholds, switch between Celsius and Fahrenheit, and reset the display easily.

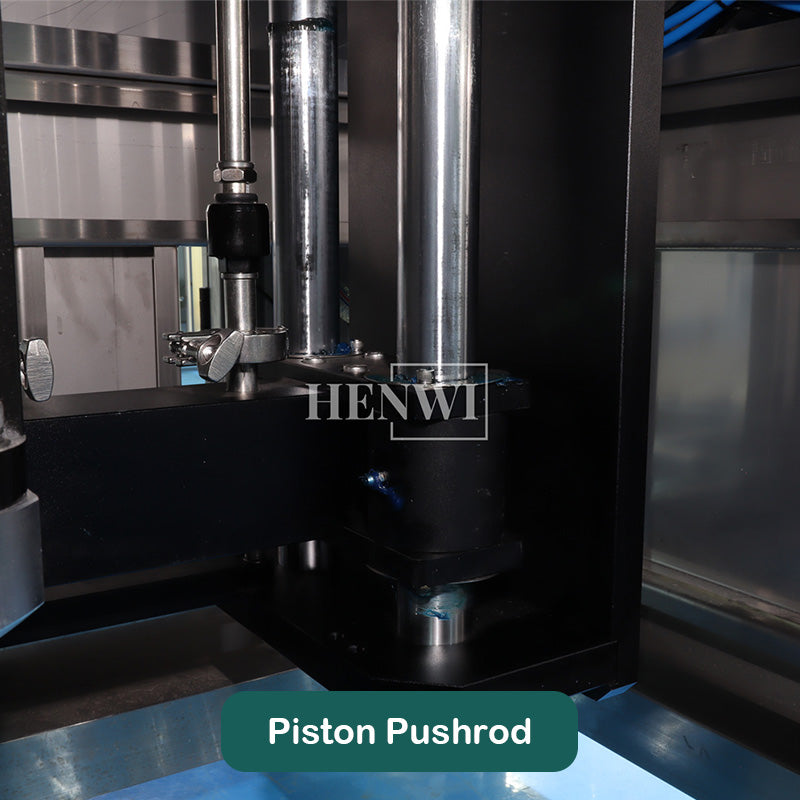

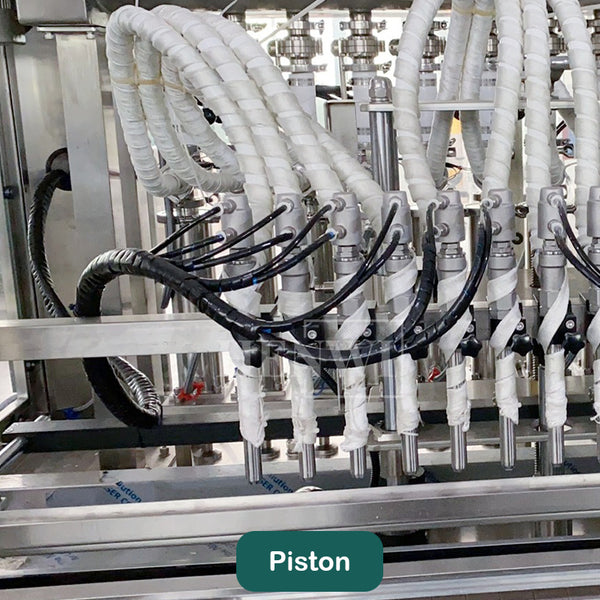

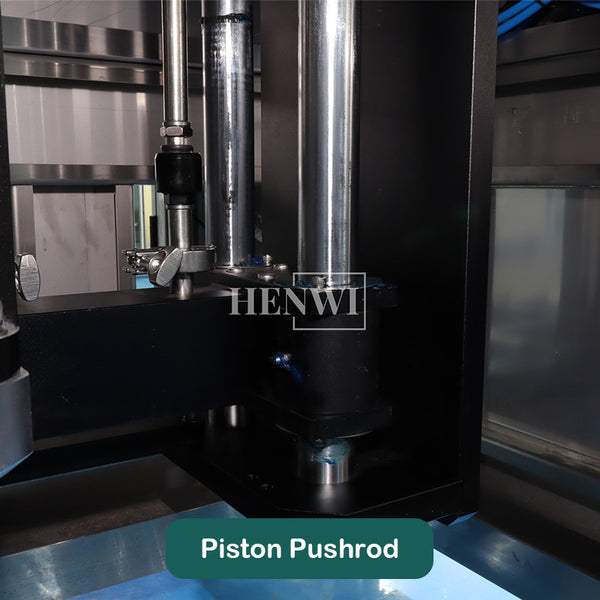

Servo Constant Temperature Piston Cylinder

The constant temperature piston cylinder is a key component of the automatic constant temperature servo piston filling machine. It plays a crucial role in ensuring accurate and consistent filling of various materials, particularly those that are sensitive to temperature changes.

#### 1. **Construction and Design**

- **Durable Materials**: The piston cylinder is typically constructed from high-quality stainless steel 316L, which provides excellent corrosion resistance and durability, making it suitable for harsh industrial environments.

- **Thermal Insulation**: The cylinder is designed with thermal insulation to maintain a consistent temperature during the filling process. This feature is critical for products whose viscosity and other properties can change significantly with temperature variations.

#### 2. **Functionality**

- **Precise Piston Movement**: The piston within the cylinder is driven by a servo motor, allowing for precise control over the filling volume and speed. The servo control ensures that the piston can adjust its position accurately to dispense the exact amount of material required.

- **Constant Temperature Regulation**: Integrated heating or cooling elements within the piston cylinder maintain the material at a specified temperature throughout the filling process. This is essential for ensuring that temperature-sensitive materials remain stable and retain their desired characteristics.

#### 3. **Performance Advantages**

- **High Filling Accuracy**: The design of the constant temperature piston cylinder allows for high precision in filling volumes, typically within ±0.3% to ±0.5%. This level of accuracy is critical in industries such as pharmaceuticals and food processing, where exact dosages are necessary.

- **Versatile Material Handling**: The cylinder can accommodate a wide range of materials, including low to high-viscosity liquids, pastes, and products containing particulates, making it suitable for diverse applications.

Servo Motor

Servo Driver

Drive belt

With limit screw lifting drive piston

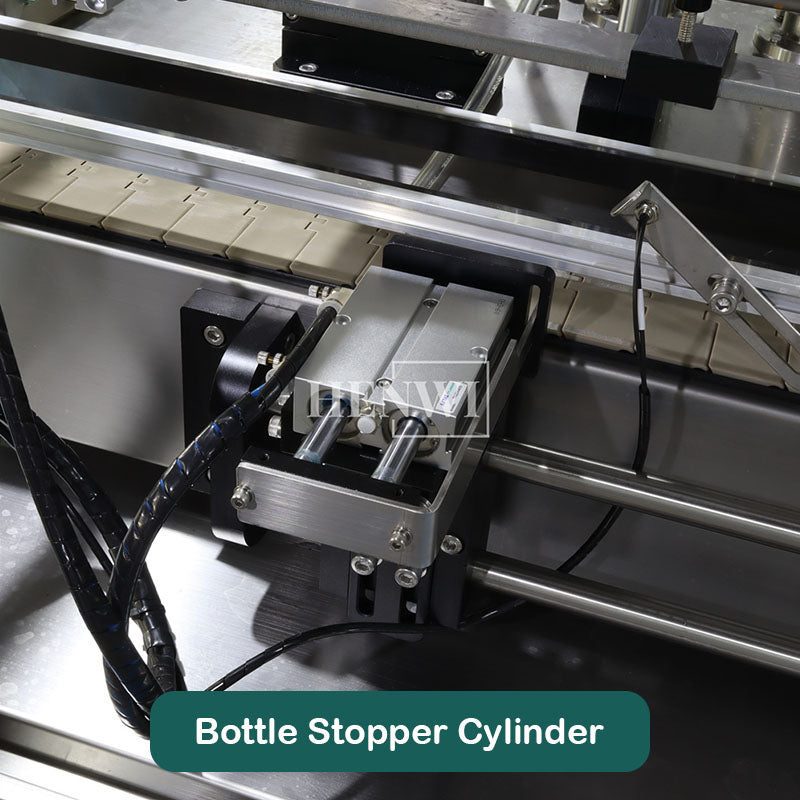

Conveyor Belt

The conveyor belt is an integral component of the automatic servo piston filling machine, facilitating the efficient transport of containers throughout the filling process.

#### 1. **Construction and Material**

- **Durable Materials**: The conveyor belt is made from high-quality materials such as PVC, which provide excellent resistance to wear, chemical exposure, and varying temperature conditions.

- **Modular Design**: Many conveyor belts are designed with modular components, allowing for easy customization and flexibility in configuration according to the layout of the production line.

#### 2. **Functionality**

- **Container Transport**: The primary function of the conveyor belt is to move containers (such as bottles, jars) into position for filling and out after the filling process is complete. This automated movement enhances workflow efficiency.

- **Synchronization with Filling Process**: The conveyor belt is synchronized with the filling machine's operation to ensure that containers are precisely positioned under the filling nozzles, minimizing any delays and reducing the risk of spills or misalignment.

#### 3. **Design Features**

- **Adjustable Speed**: The conveyor speed can be adjusted to match the filling rate, ensuring optimal coordination between the filling and conveying processes. This adjustability helps maintain production efficiency.

#### 4. **Performance and Reliability**

- **Continuous Operation**: The conveyor belt system is designed for continuous operation, providing a reliable transport mechanism that minimizes downtime during production.

- **Low Maintenance**: Modern conveyor belts are engineered for low maintenance requirements, featuring self-lubricating bearings and robust construction that reduce the need for frequent repairs.

Conveyor speed inverter

Conveyor motor

200L Stainless Steel 316 Hopper with Automatic Replenishment and Heating Stirring

The 200L stainless steel 316 hopper equipped with automatic replenishment and heating stirring is a vital component of the automatic constant temperature servo piston filling machine. This hopper is designed to store and prepare materials for filling while ensuring optimal conditions for various liquids and pastes.

#### 1. **Construction and Design**

- **High-Quality Material**: Constructed from stainless steel 316, the hopper offers excellent corrosion resistance, durability, and compliance with food safety and pharmaceutical standards. This material is particularly beneficial in applications involving aggressive chemicals or temperature-sensitive products.

- **Capacity**: The hopper has a generous capacity of 200 liters, making it suitable for high-volume production lines and reducing the frequency of material replenishment.

#### 2. **Functionality**

- **Automatic Replenishment System**: The hopper is equipped with an automatic replenishment system that ensures a continuous supply of material. This feature is critical for maintaining production efficiency, as it reduces downtime associated with manual refilling. The system can be integrated with sensors to monitor material levels and trigger replenishment as needed.

- **Heating and Stirring Mechanism**: The hopper includes an integrated heating system and stirring mechanism that maintains the material at a consistent temperature and ensures uniform mixing. This is particularly important for high-viscosity liquids and pastes that may separate or settle during storage.

#### 3. **Performance Advantages**

- **Temperature Control**: The heating system allows for precise temperature management, which is essential for maintaining the properties of temperature-sensitive materials. The hopper can effectively manage materials that require specific temperatures for optimal performance and consistency.

- **Homogeneous Mixture**: The stirring mechanism ensures that materials are well-mixed and homogeneous before filling, reducing the risk of inconsistencies in the final product. This is particularly beneficial for products that contain solid particulates or that tend to separate over time.

#### 4. **Maintenance and Cleaning**

- **Easy Access for Cleaning**: The design of the hopper allows for easy access for cleaning and maintenance. Smooth internal surfaces minimize residue buildup and facilitate thorough cleaning.

- **CIP Compatibility**: The hopper can be integrated with Clean-In-Place (CIP) systems, allowing for efficient and effective cleaning without requiring disassembly, thereby improving operational efficiency and hygiene.

Material level sensor

Material tank drain

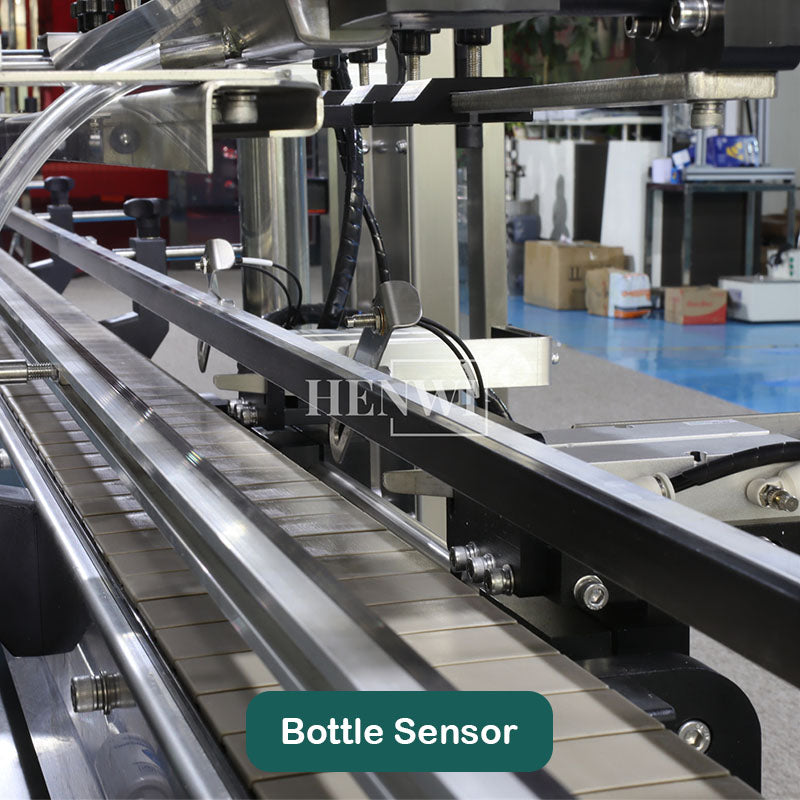

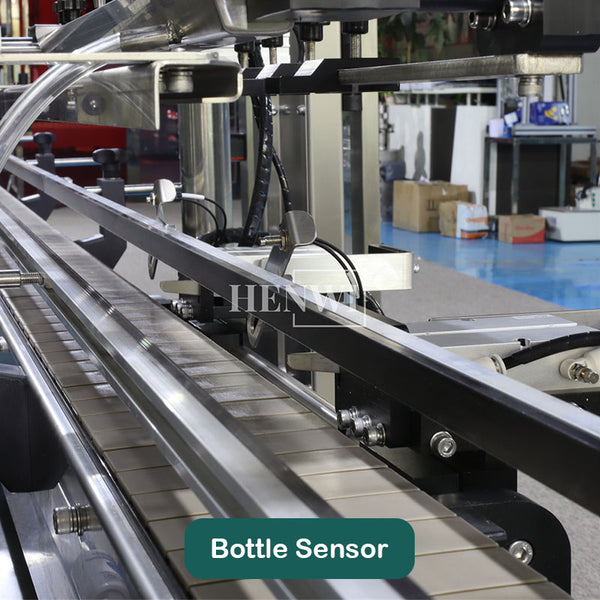

Bottle Detect Sensor

The Keyence bottle detection photoelectric sensor in the filling machine is crucial for accurately detecting the presence, position, and movement of bottles, ensuring the smooth operation of the automated filling process.

1. **High-Precision Bottle Detection**: The sensor can quickly and accurately detect whether a bottle is in place, ensuring each bottle stops precisely at the filling position, preventing filling errors or material waste due to missing or misaligned bottles.

2. **Non-Contact Detection**: Utilizing optical sensor technology, the Keyence sensor detects bottles without physical contact, avoiding the wear or contamination that may occur with traditional mechanical detection methods. This is especially beneficial for high-speed automated lines and industries with stringent hygiene requirements, such as food and pharmaceuticals.

3. **High Response Speed**: As filling lines often operate at high speeds, the fast response time of the Keyence sensor ensures that bottles are detected promptly, with real-time feedback to the PLC system for precise filling actions. Even when bottles move quickly, the sensor can reliably detect them.

4. **Stability and Interference Resistance**: The Keyence sensor is highly resistant to environmental interference, allowing stable operation in complex production environments. It avoids detection errors caused by factors like ambient light, dust, or varying bottle transparency. The sensor can accurately detect even transparent or reflective bottles.

5. **Multiple Detection Modes**: The Keyence sensor supports various detection modes, such as through-beam or reflective, and can be configured based on the specific requirements of the filling line. This flexibility accommodates different bottle sizes, shapes, and materials, ensuring adaptability in the filling process.

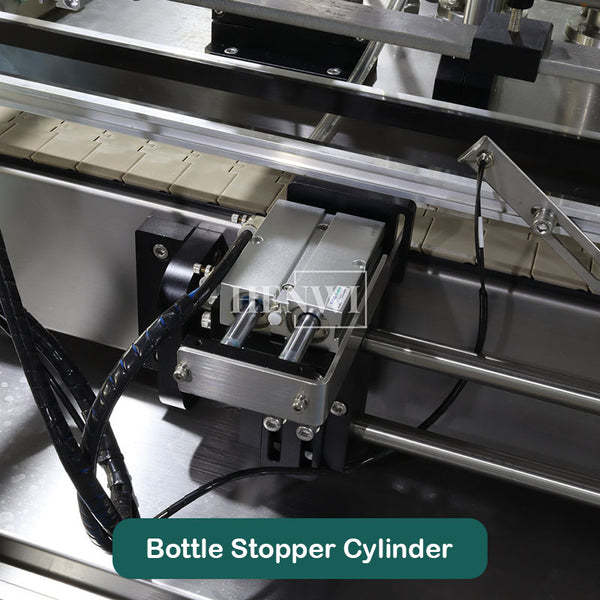

Bottle Stopper

Air pressure regulating valve

Spare parts

Welding

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.