Colloid mill

- Prix

- $1,570

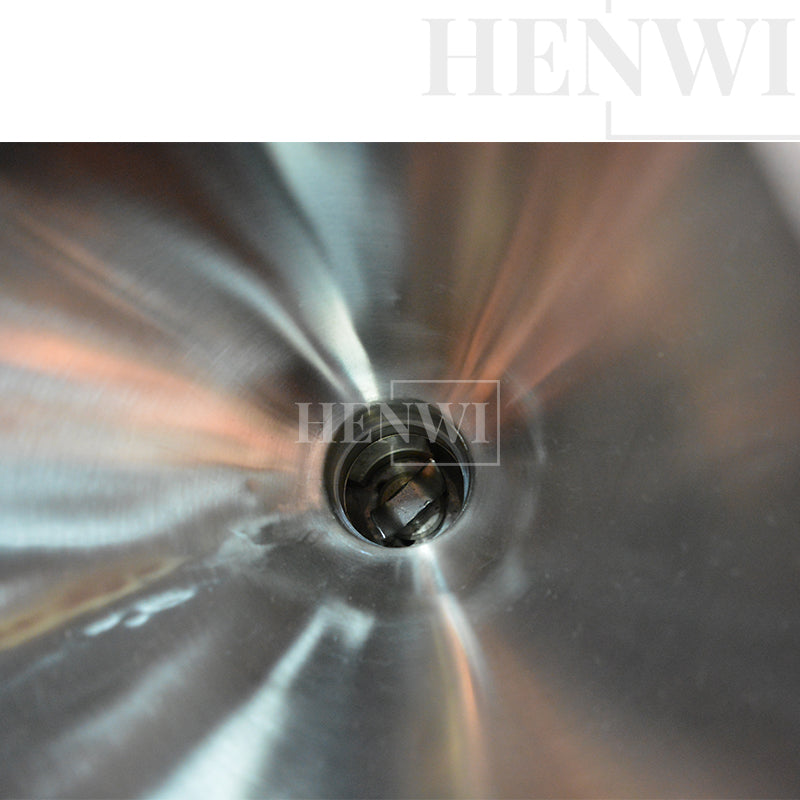

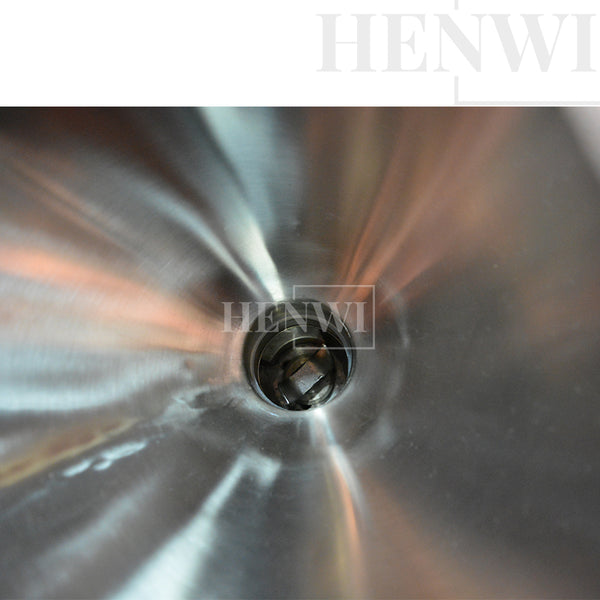

Colloid Mill Working Principle

A colloid mill is a high-efficiency equipment that uses an electric motor to drive a rotating rotor (or rotor) and a stationary stator (or stator) at high speeds. In operation, one part rotates while the other remains stationary. The material being processed is pressurized either by its own weight or external pressure (typically generated by a pump) and is forced downward through the gap between the rotor and stator. The gap between the rotor and stator is adjustable. During this process, the material is subjected to a combination of shear forces, friction, high-frequency vibrations, and high-speed vortexes, which effectively emulsify, disperse, homogenize, and grind the material, achieving ultra-fine pulverization and emulsification.

Applications of the Colloid Mill

Colloid mills are widely used across various industries, especially for materials that require fine processing, homogenization, and emulsification. The key application areas include:

-

Food Industry:

- Aloe vera, pineapple, sesame, fruit tea, ice cream, mooncake fillings, butter, fruit jams, fruit juices, soybeans, bean paste, peanut butter, protein milk, soy milk, dairy products, malted milk, flavorings, and various beverages.

-

Chemical Industry:

- Paints, pigments, dyes, coatings, lubricating oils, lubricants, diesel, petroleum catalysts, emulsified asphalt, adhesives, detergents, plastics, fiberglass, leather, emulsions, and more.

-

Daily Chemicals:

- Toothpaste, detergents, shampoos, shoe polish, high-end cosmetics, bath gels, soap, balms, and more.

-

Pharmaceutical Industry:

- Various syrups, nutritional solutions, traditional Chinese medicine, ointments, biological products, cod liver oil, pollen, royal jelly, vaccines, various ointments, oral liquids, injections, and infusions.

-

Construction Industry:

- Various coatings, including interior and exterior wall paints, anticorrosion waterproof coatings, cold porcelain coatings, multi-color paints, ceramic glazes, and more.

-

Other Industries:

- Plastics, textiles, paper-making, coal flotation agents, nanomaterials, and other environmentally friendly production needs.

Advantages of the Colloid Mill

Compared to pressure homogenizers, the colloid mill is a centrifugal-type device with the following advantages:

- Simple Structure: The design is simple, making the equipment easy to maintain and operate.

- Suitable for High-Viscosity Materials: It works well with high-viscosity and coarse particles, offering greater versatility.

- Efficient Fine Grinding: The combination of shear, friction, and centrifugal forces achieves efficient material fine grinding and homogenization.

However, the colloid mill also has some drawbacks:

- Variable Flow Rate: Due to the centrifugal motion, the flow rate of the colloid mill is not constant, and it can vary significantly with materials of different viscosities. For instance, the flow rate can differ by a factor of 10 when processing thick paint and thin milk-like liquids with the same equipment.

- Heat Generation: The high-speed friction between the rotor and stator generates heat, which may cause denaturation of heat-sensitive materials.

- Wear and Tear: The surfaces of the rotor and stator are subject to wear, and once worn, the fine grinding effect significantly diminishes. Regular maintenance and part replacement are necessary.

Colloid Mill Technical Specifications

The following table provides a detailed breakdown of the colloid mill parameters across different power ranges, helping you select the most suitable equipment based on your production needs:

| Power | Motor Power | Speed | Particle Size (Fineness) | Capacity | Grinding Disc Diameter | Cooling Water Pipe Diameter | Outlet Diameter | Inlet Diameter | Dimensions | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 1.5 kW | 1.5 kW | 2800 rpm | 5-30 microns | 20-50 L/h | 100 mm | 20 mm | 25 mm | 30 mm | 500 x 300 x 700 mm | 50 kg |

| 2.2 kW | 2.2 kW | 2800 rpm | 2-30 microns | 50-100 L/h | 120 mm | 25 mm | 30 mm | 35 mm | 600 x 350 x 800 mm | 80 kg |

| 3 kW | 3 kW | 2800 rpm | 2-25 microns | 100-150 L/h | 130 mm | 30 mm | 35 mm | 40 mm | 650 x 400 x 900 mm | 100 kg |

| 4 kW | 4 kW | 2800 rpm | 2-20 microns | 150-200 L/h | 150 mm | 35 mm | 40 mm | 45 mm | 700 x 450 x 1000 mm | 120 kg |

| 5.5 kW | 5.5 kW | 2800 rpm | 2-15 microns | 200-250 L/h | 160 mm | 40 mm | 45 mm | 50 mm | 800 x 500 x 1200 mm | 160 kg |

| 7.5 kW | 7.5 kW | 2800 rpm | 1-10 microns | 250-350 L/h | 180 mm | 45 mm | 50 mm | 55 mm | 900 x 550 x 1300 mm | 180 kg |

| 11 kW | 11 kW | 2800 rpm | 1-8 microns | 350-500 L/h | 200 mm | 50 mm | 55 mm | 60 mm | 1000 x 600 x 1400 mm | 220 kg |

| 15 kW | 15 kW | 2800 rpm | 1-5 microns | 500-700 L/h | 250 mm | 60 mm | 70 mm | 80 mm | 1200 x 700 x 1500 mm | 250 kg |

Summary

The colloid mill is a highly efficient device used for fine grinding, homogenizing, and emulsifying a wide range of materials. Its robust design and versatile applications make it ideal for industries such as food, pharmaceuticals, chemicals, and more. By employing centrifugal forces, shear, friction, and high-speed vortex effects, the colloid mill ensures that materials are finely ground, emulsified, and homogenized efficiently.

With various power options available, you can select the most suitable colloid mill based on your production requirements. Whether you need to process high-viscosity liquids, coarse particles, or heat-sensitive materials, the colloid mill provides an optimal solution for your manufacturing needs.

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.