1000L Perfume Production Line

- Prix soldé

- $22,880

- Prix habituel

- $33,000

- Vous sauvegardez

- $10,120 (31%)

Semi-automatic perfume production lines are usually the choice of small and medium-sized perfume manufacturers. They can achieve a certain degree of automation, reduce manual operations, and reduce costs.

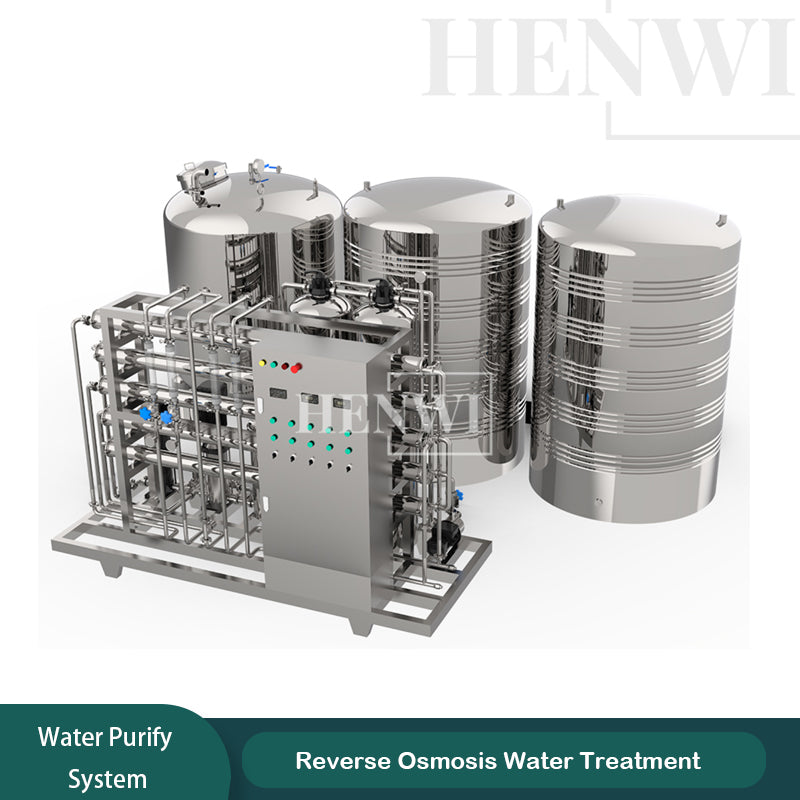

### 1. **Water treatment equipment**

- **Reverse osmosis (RO) water treatment system**: used to remove impurities, heavy metals, microorganisms, etc. in water to ensure the high purity of production water and meet the hygiene requirements of perfume production.

- **Ultraviolet sterilizer**: further sterilize to ensure that there are no microorganisms in the water to prevent pollution.

### 2. **Frozen mixing tank**

- **Stainless steel tank**: used for mixing perfume raw materials, mainly including essences, alcohol and water. The tank generally has a stirring function to ensure that the raw materials are fully mixed.

- **Stirring system**: usually a stirring device mounted on the top, which can effectively stir the perfume raw materials to ensure uniform mixing.

- **Temperature control system**: some perfumes need to control the temperature during the production process, and the temperature control system can ensure that the mixture is kept in a suitable temperature range.

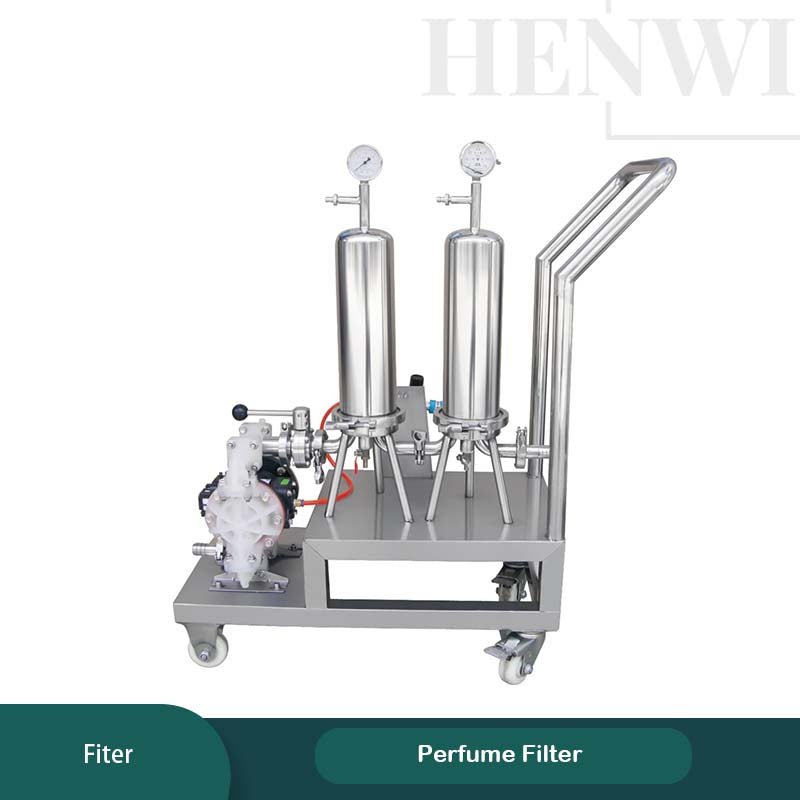

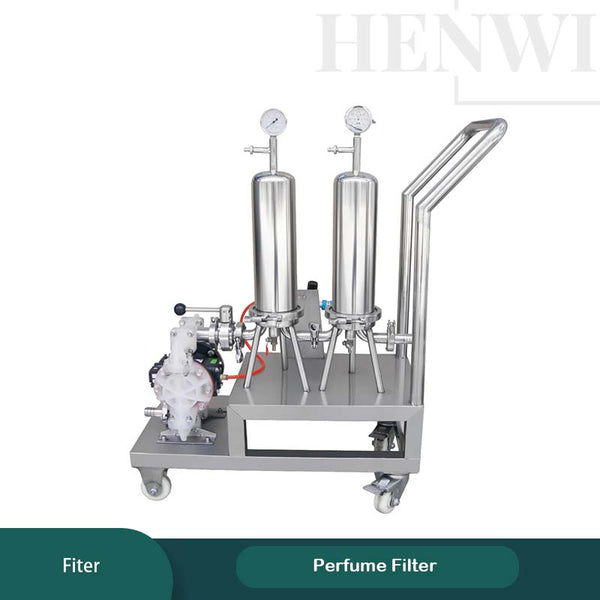

### 3. **Perfume filtration equipment**

- **Plate and frame filter**: used for preliminary filtration of perfume liquid to remove particles or insoluble substances that may be generated during the mixing process.

- **Precision filter**: Performs finer filtration to ensure the purity of perfume liquid, and is often used to remove tiny suspended matter and impurities.

### 4. **Filling machine**

- **Semi-automatic vacuum filling machine**: Used to fill perfume liquid into bottles, and the operator needs to manually place the bottles. The vacuum principle is used to fill perfume into bottles, which is suitable for bottles of various shapes and materials.

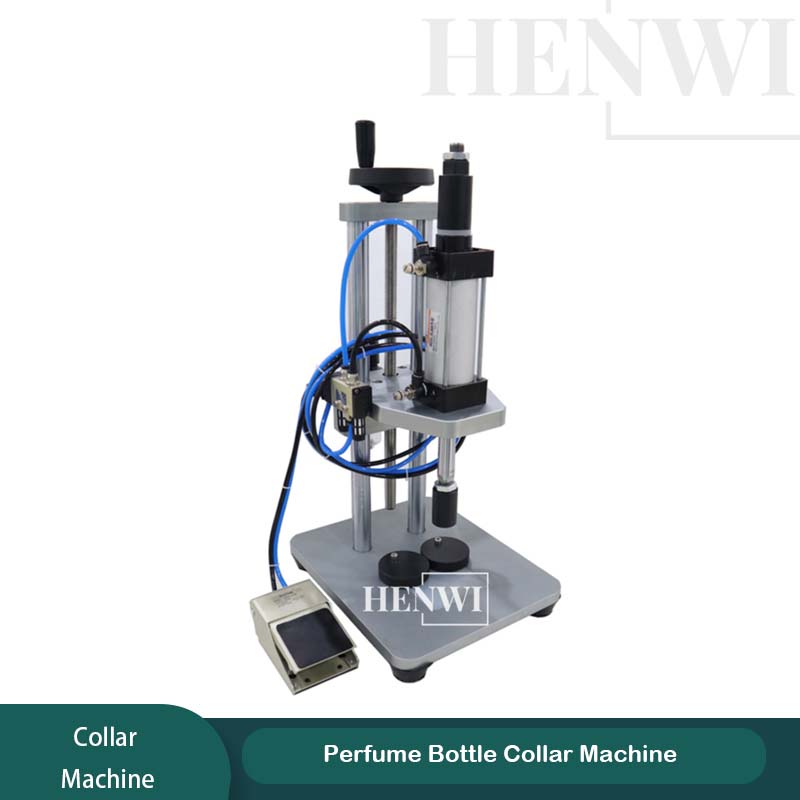

### 5. **Capping machine**

- **Semi-automatic capping machine**: Used to press the nozzle or bottle cap onto the perfume bottle. The operator manually places the nozzle or bottle cap onto the bottle, and the machine presses it. Suitable for bottle caps and nozzles of different specifications.

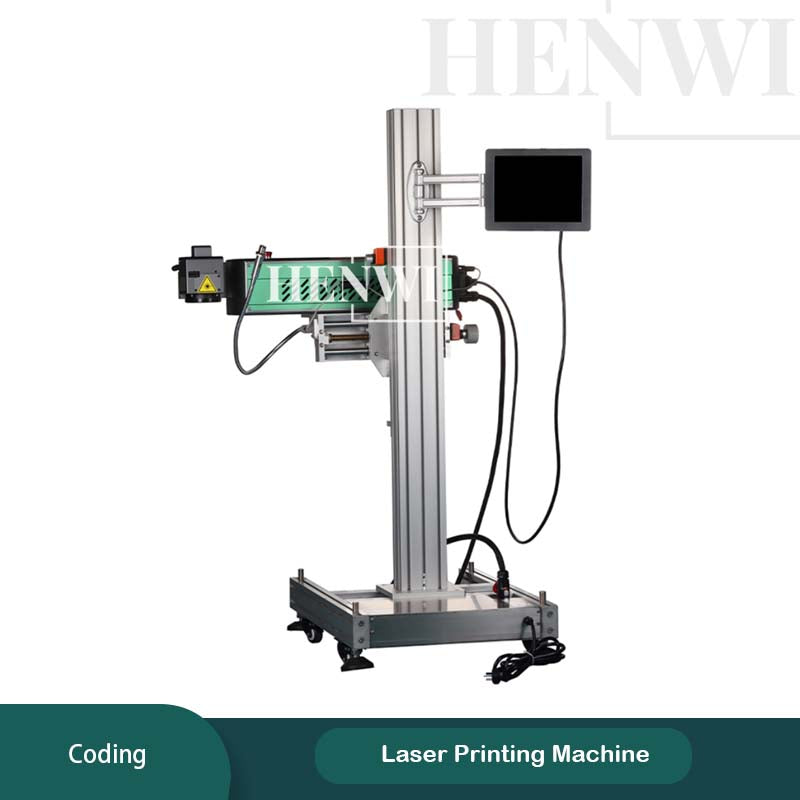

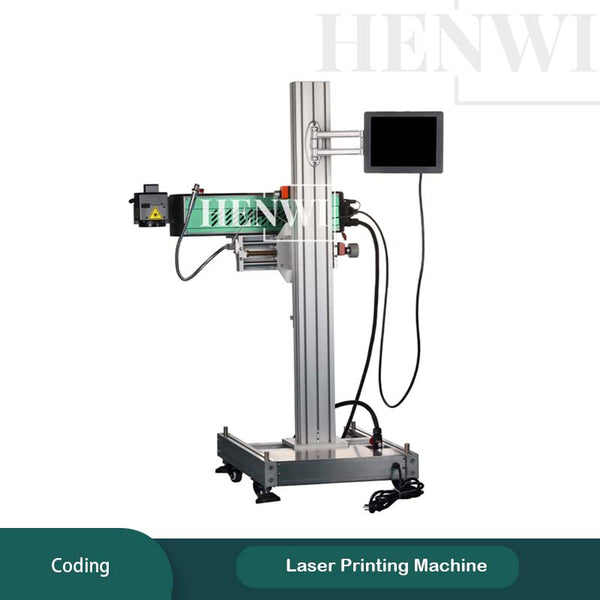

### 7. **Coding machine**

- **Laser coding machine**: Used to print production date, batch number and other information on bottles or labels.

### 8. **Packaging equipment**

- **Heat shrink packaging machine**: Used to package perfume bottles, wrap the bottles with heat shrink film to form a sealed package. This equipment is usually used for the packaging of final products.

### 9. **Conveyor belt (optional)**

- In some semi-automatic production lines, a simple conveyor belt system is configured to transfer products from one production step to the next step, reducing manual handling.

### 10. **Storage tank**

- **Finished product storage tank**: used to store perfume that has been mixed and filtered, ready to be filled into bottles.

Application

Semi-automatic perfume production lines are mainly used in the production process of small and medium-sized perfume manufacturers and can produce a variety of perfume types. According to product positioning, packaging and market demand, common perfume types include:

1. **Eau de Toilette (EDT)**

Eau de Toilette is a common perfume type on the market with a relatively low fragrance concentration, suitable for daily use.

2. **Perfume (Parfum or Extrait de Parfum)**

This perfume has a high fragrance concentration and strong durability, and is usually used in the high-end market

3. **Eau de Cologne (EDC)**

Cologne is the perfume with the lowest fragrance concentration, suitable for summer or daily fresh use

4. **Eau de Parfum (EDP)**

It is between perfume and eau de toilette and has a higher fragrance concentration.

5. **Body Mist**

Body spray is used to refresh the body and replenish fragrance. It is usually low in concentration and suitable for frequent use.

6. **Customized perfume**

The semi-automatic production line is also suitable for the production of customized perfumes, meeting the needs of small batches and highly personalized perfumes.

Parameter

| Model: HWPF-ST-500L |

| Capacity: 500 Liters/Batch |

| Time for per batch: 1 hour to several days (Depends: aging etc) |

| Output: Depends: blending, aging, etc. |

| Applicable bottle volume: 5-500ml |

| Applicable bottle shape: Round & Square |

| Number of workers needed: 5-7people |

| Total power: 20KW |

| Voltage: 220V & 380 (can be customized) |

| Total floor space: L12000*W5000*H2000mm |

Content

| 250L reverse osmosis water treatemnt * 1 set |

| 40W UV lamp * 1 set |

| 370W VDF water pump * 1 set |

| 500L SS304 water tank * 3 sets |

| 500L perfume cooling & mixing tank * 1 set |

| Filter * 1 set |

| 500L SS316 movable mixing storage tank * 2 sets |

| Semi-automatic 4 nozzles vacuum filling machine * 1 set |

| Semi-automatic crimping machine * 1 set |

| Semi-automatic collar machine * 1 set |

| 6M conveyor * 1 set |

| Laser printing machine * 1 set |

| 4KW air compressor * 1 set |

250L/Hr Reverse Osmosis Water Treatment System |

|

In the perfume production process, water is one of the important solvents, especially for diluting essences and alcohol ingredients. Therefore, the purity of water is crucial to the quality of perfume. **Reverse osmosis water treatment equipment** (RO system) is mainly used in perfume production lines to provide high-purity water, remove impurities, ions and microorganisms in water, and ensure that the quality of production water meets the standards. ### **Description of reverse osmosis water treatment equipment** 1. **Basic principle** Reverse osmosis (RO) is a technology that filters impurities in water through a semi-permeable membrane. Under high pressure, water passes through a reverse osmosis membrane with extremely small pores, and water molecules can pass through, while most dissolved solids (such as salts, minerals), organic matter, microorganisms and other impurities are retained on one side of the membrane, thereby producing pure water. 2. **Key components** - **Inlet water pretreatment system**: usually includes sand filters, carbon filters and softeners to remove large particles, suspended matter, chlorine and hardness, etc., to extend the service life of the reverse osmosis membrane. - **High-pressure pump**: used to apply sufficient pressure to the reverse osmosis membrane to make water molecules pass through the membrane and effectively separate impurities. |

500L Perfume Freezer Mixing Tank |

|

**Freezer mixer** plays an important role in perfume production lines. It is mainly used to mix ingredients such as fragrance, alcohol and deionized water, and promote the maturity and stability of perfume through the freezing process. Its main function is to ensure the full integration of perfume ingredients and prevent the fragrance from deteriorating or causing adverse reactions in a low temperature environment. ### **How does the freezer mixer work** 1. **Mixing function** 2. **Freezing function** ### **Key components of the freezer mixer** 1. **Mixing system** ### **Application functions of the refrigerated mixer** |

Perfume Filter |

| Microfilters are key components in perfume production lines, mainly used to remove tiny particles and impurities from liquids to ensure the clarity and purity of perfumes. Its main features include: 1. **High-precision filtration**: Microfilters can filter out particles with a diameter of 0.1 microns and below, effectively removing suspended matter, bacteria and other tiny contaminants. 2. **Material selection**: Chemically resistant materials such as stainless steel or polymers are usually used to ensure compatibility with perfume ingredients and prevent contamination. 3. **Design and maintenance**: Designed for easy installation and disassembly, easy cleaning and replacement, ensuring the efficiency of the production line. 4. **Process integration**: Microfilters are usually integrated in key links of the production process, such as before mixing and filling, to maintain the stability and quality of the perfume. |

500L Pneumatic stirring mobile sealed storage tank |

| The pneumatic stirring mobile sealed aging tank in the perfume production line is a device designed for the aging and mixing process in the perfume production process. It is mainly used for mixing, aging and storage of perfume formulas before filling. The equipment combines pneumatic stirring, mobile design and sealing structure to ensure that the perfume is evenly mixed during the aging process while avoiding volatilization or contamination of the essence. ### 1. **Equipment function** - **Pneumatic stirring**: The stirring device is driven by a pneumatic motor to ensure that the perfume raw materials are evenly mixed in the tank, maintain a stable liquid consistency, and avoid stratification or uneven composition. - **Sealing design**: The tank body is equipped with an efficient sealing system to prevent the perfume raw materials from contacting the outside air during the aging process, avoiding oxidation, contamination or aroma volatilization, and ensuring product quality. - **Mobile structure**: The tank body is equipped with a high-strength mobile device, and the operator can easily move the tank body to different workstations, which is convenient for flexible scheduling and operation in the production line. ### 2. **Workflow** - **Raw material injection**: The operator injects the perfume raw materials (essence, alcohol, etc.) into the aging tank and closes the tank body through the sealing cover. - **Pneumatic stirring**: Start the pneumatic motor to drive the internal agitator to mix the perfume evenly. The stirring speed can be adjusted as needed to ensure that the ingredients of different formulas are evenly blended. - **Aging storage**: After mixing, the perfume is sealed and aged in the tank to ensure the stability of the formula and the perfect fusion of the aroma. - **Moving to the filling station**: After aging, the operator can move the tank to the filling station through the mobile device for subsequent production steps. ### 2. **Technical parameters** - **Pneumatic motor power**: The power range of the pneumatic agitator is usually 0.5-2.0 horsepower (HP), and the specific power can be selected according to the tank volume and stirring requirements. - **Tank capacity**: According to production requirements, the tank capacity can range from tens of liters to hundreds of liters, and the common capacity is 50L, 100L, 200L, etc. - **Stirring speed**: The speed of the agitator is adjustable, usually between 50-500 RPM (revolutions per minute) to adapt to perfume formulas with different viscosities and ingredients. - **Sealing pressure**: The tank has efficient sealing performance and can usually withstand a certain internal pressure to prevent the loss of volatile components in the perfume. - **High safety**: Pneumatic systems are safer than electric stirring, especially when used in environments with flammable components (such as alcohol in perfume), without sparks or explosion risks. - **Easy maintenance**: The tank has a simple design and is easy to clean and maintain, suitable for frequent use and high hygiene requirements in production environments. |

| Semi-automatic 4 Nozzles Vacuum Filling Machine |

|

The semi-automatic pneumatic 4-head vacuum filler in the perfume production line is a device designed for liquid perfume products. It can efficiently and accurately fill perfume into bottles. The equipment adopts pneumatic drive and vacuum-assisted technology to ensure that there are no bubbles or spills in the filling process, and it can adapt to perfume bottles of various specifications. The equipment is equipped with four filling heads, which can handle multiple bottles at the same time, significantly improving production efficiency, and is very suitable for small and medium-sized batch perfume production lines. ### 1. **Equipment function** - **Pneumatic drive**: The filling process is controlled by the pneumatic system to achieve precise liquid distribution. The whole process is stable and efficient. - **Vacuum filling**: The air in the bottle is extracted by vacuum technology, and filling is carried out under negative pressure to prevent bubbles from being generated, while ensuring consistent filling volume. - **Multi-head design**: The equipment is equipped with four filling heads, allowing four perfume bottles to be filled at the same time, greatly improving the filling efficiency of the production line. ### 2. **Workflow** - **Bottle preparation**: The operator places the perfume bottle in the filling position, and the bottle mouth is aligned with the filling head. - **Start vacuum filling**: After the pneumatic system is started, the equipment exhausts the air in the bottle through vacuum suction, and then the liquid perfume flows into the bottle under the action of vacuum pressure. - **Automatic liquid level control**: The equipment can control the filling volume by setting the liquid level or vacuum degree to avoid overflow or insufficient filling. - **Bottle removal**: After the filling is completed, the operator takes out the filled perfume bottle, and the equipment can enter the next round of filling. ### 3. **Core features** - **Precision filling**: Vacuum filling technology can ensure that the amount of liquid filled each time is consistent, and the filling error is extremely small, which is suitable for perfume production with high precision requirements. - **No bubbles, no leakage**: The vacuum filling process can completely exhaust the air in the bottle, ensuring that the liquid is free of bubbles, and there will be no perfume overflow or residual gas in the bottle. - **Efficient multi-head design**: Four filling heads can be filled at the same time, greatly shortening the filling time of a single bottle, suitable for medium-volume production needs. - **Easy to adjust**: The equipment can be adjusted according to the specifications of the perfume bottle and the required filling volume to meet the filling needs of different bottle types and capacities. ### 4. **Technical parameters** - **Pneumatic pressure**: 0.5-0.8 Mpa, ensuring smooth operation of the equipment during the filling process. - **Filling accuracy**: The filling accuracy is as high as ±1%, which can meet the precise filling needs of high-value liquids such as perfume. - **Applicable bottle diameter**: The equipment is suitable for perfume bottles with a variety of bottle diameters, usually 10-50mm in diameter. - **Filling speed**: Hundreds of bottles of perfume can be processed per hour, and the specific efficiency depends on the operator's proficiency and the size of the bottle.

|

| Semi-automatic Bottle Cap Crimping Machine |

|

The semi-automatic pneumatic bottle cap gripper in the perfume production line is a device specially used for grabbing and installing bottle caps during the packaging process of perfume bottles. It is particularly suitable for operations where the bottle caps need to be precisely positioned and pressed. The equipment uses a pneumatic system to drive the gripper to accurately grab and place the bottle cap so that the bottle cap fits tightly with the perfume bottle mouth. The semi-automatic design of the equipment ensures convenient operation and production efficiency, and is widely used in small and medium-sized perfume production lines. ### 1. **Equipment function** - **Pneumatic gripping**: The gripper is driven by a pneumatic system to firmly grab the bottle cap and accurately position it on the perfume bottle mouth to avoid the bottle cap from being skewed or loose. - **Semi-automatic operation**: The operator manually places the bottle, and the equipment automatically grabs the bottle cap and installs it, which greatly reduces manual operation of the bottle cap and improves efficiency. - **Multiple bottle caps adaptability**: The equipment is suitable for various types of perfume bottle caps, such as spray caps, screw caps and press caps, and has a wide range of adaptability. ### 2. **Workflow** - **Bottle positioning**: The operator places the perfume bottle on the bottle support device of the equipment to ensure that the bottle is fixed. - **Bottle cap grabbing**: After the equipment is started, the pneumatic gripper grabs the bottle cap from the bottle cap tray and accurately aligns it with the bottle mouth. - **Bottle cap installation**: The gripper automatically places the bottle cap and applies appropriate pressure to press the bottle cap on the perfume bottle through the pneumatic device. - **Complete operation**: After the bottle cap is grabbed, the operator takes out the sealed perfume bottle and continues the operation of the next bottle. ### 3. **Technical parameters** - **Pneumatic pressure**: The equipment relies on the pneumatic system to work, and the air pressure range is usually 0.4-0.8 Mpa to ensure the stability of grabbing and installation. - **Applicable bottle cap diameter**: The adaptable bottle cap diameter range is 10-50mm, and the specific parameters can be adjusted according to actual production needs. - **Grasping force adjustment**: The gripper's strength can be adjusted according to the material and specifications of the bottle cap to ensure that the bottle cap will not be damaged when grabbed. - **Production Efficiency**: Hundreds of perfume bottles can be processed per hour, depending on the specifications of the bottles and caps and the proficiency of the operators.

|

| Semi-automatic Bottle Cap Collar Machine |

| The semi-automatic pneumatic bottle cap centering machine in the perfume production line is a device specially used for bottle cap centering operation during the perfume bottle packaging process. It uses a pneumatic system as a power source, combined with a semi-automatic operation mode, so that the perfume bottle cap can be quickly and accurately installed on the perfume bottle. The equipment is suitable for different types of perfume bottle caps, such as spray caps, press caps, etc., especially in scenes with moderate production volume and high requirements. ### 1. **Equipment function** - **Pneumatic drive**: Stable pressure is generated through the pneumatic system to accurately and firmly press the bottle cap on the perfume bottle to ensure a tight and damage-free seal. - **Semi-automatic operation**: The operator manually places the perfume bottle and bottle cap in the specified position. After the button is started, the equipment accurately fits the bottle cap through pneumatic control. - **Multiple bottle caps adaptability**: Adjustable molds and fixtures make the equipment suitable for bottle caps of various specifications and shapes, with strong adaptability. ### 2. **Workflow** - **Place bottle caps and bottles**: The operator places the perfume bottle and the corresponding bottle caps on the positioning device of the equipment to ensure that the bottle and bottle cap are in the correct position. - **Start the pneumatic system**: After pressing the start button, the pneumatic system drives the upper pressing mold to accurately press the bottle cap into the mouth of the perfume bottle. - **Take out the bottle**: After the bottle cap is installed, the equipment automatically resets, and the operator takes out the packaged perfume bottle and continues the next cycle. ### 3. **Core features** - **High-precision packaging**: The pressure controlled by the pneumatic system is accurate and can be adjusted according to the material and size of the bottle cap to avoid excessive compression or loosening, ensuring the stability and consistency of each packaging. - **Simple operation**: The semi-automatic design only requires manual placement of bottles and bottle caps, reducing the error of manual operation. The equipment is easy to use and suitable for workers at different levels. - **Easy adjustment**: The mold and positioning device of the equipment can be flexibly adjusted to adapt to perfume bottles and bottle caps of different specifications and heights, and switching production specifications is quick and easy. - **Safety guarantee**: Equipped with safety protection devices to prevent bottle breakage or other accidents during operation, ensuring the safety of operators. ### 4. **Technical parameters** - **Pneumatic pressure**: The equipment usually operates with an air pressure range of 0.5-0.8 Mpa, which can ensure stable pressing of bottle caps. - **Applicable bottle cap size**: It can handle bottle caps of different diameters, usually in the range of 10-50mm, suitable for perfume bottles of different sizes. - **Production efficiency**: Depending on the operator's proficiency, hundreds of bottles can be processed per hour, suitable for medium-volume production needs. |

| Laser Printing Machine |

|

Laser inkjet printers are common marking equipment in perfume production lines. They are mainly used to print production date, batch number, serial number, barcode, QR code and other information on perfume bottles or packaging. Compared with traditional inkjet printers, laser inkjet printers have many advantages. **Working principle of laser inkjet printers** |

6M Conveyor |

| In semi-automatic perfume production, conveyors (conveyor belts) are used to transfer perfume bottles and related components from one process to the next. ### 1. **Material and design** - **Material**: The conveyor belt is made of a stainless steel frame and a plastic or rubber belt surface material to ensure that the alcohol or other chemical components in the perfume will not damage the equipment. - **Design**: The conveyor belt is designed to be flexible and can be customized in length and width according to the production needs of the factory. It is usually equipped with brackets or guides to ensure that the perfume bottles remain stable during the conveyor process. ### 2. **Function and use** - **Moving bottles and components**: The main function of the conveyor belt is to move perfume bottles from one production step to another. Usually starting from the placement of empty bottles, through filling, capping, labeling, to the final packaging stage, the bottles are moved to each station in turn through the conveyor belt. - **Key link in semi-automatic production**: In semi-automatic perfume production, the conveyor belt not only connects manual operation and automated machines, but also closely links the process flows of each part. For example, the conveyor belt may stop when the bottle reaches the filler and wait for the filling to be completed before continuing to the capping process. ### 3. **Speed and Control** - **Adjustable speed**: Conveyors are usually equipped with frequency converters or control panels to adjust the speed according to the requirements of the production line. For delicate operations such as perfume filling and capping, the conveyor speed needs to be slower, while for simpler processes such as labeling or packaging, the speed can be increased accordingly. |

Semi-automatic Film Overwrapping Machine |

| Semi-automatic cigarette packaging machines are mainly used to package the produced perfume bottles or perfume boxes in semi-automatic perfume production to form a packaging form similar to a "cigarette box". Although this equipment is often used for cigarette packaging, it can also be adapted to the external packaging of products such as perfume, especially when paper boxes or plastic films are required for packaging. ### 1. **Equipment structure and function** - **Overall structure**: The semi-automatic cigarette packaging machine consists of a feeding area, a packaging forming area, a heat sealing area, a cutting device, and an output area. The design of the equipment is relatively compact and can meet the needs of small and medium-sized perfume production lines. - **Packaging material**: Film materials (such as BOPP film) or paper materials are usually used to wrap perfume boxes to ensure the beauty and integrity of the packaging. Transparent films or printed films can also be used as required. - **Packaging form**: The equipment wraps perfume bottles or perfume boxes in a form similar to cigarette packaging. The finished product packaging is characterized by compactness and flatness, and sometimes has an easy-tear strip or other opening design for consumer convenience. ### 2. **Workflow** - **Manual feeding**: In a semi-automatic production line, workers need to manually place perfume bottles or perfume boxes into the feeding area of the machine. The equipment is usually designed with an automatic positioning device to ensure that the packaging material can accurately wrap the perfume box. - **Packaging**: After the perfume bottle or box enters the packaging area, the packaging material is automatically cut and wrapped. The machine will fit the film tightly to the surface of the box and complete the initial folding and forming. - **Heat sealing and cutting**: The cigarette packaging machine uses a heat sealing device to seal the packaging film to ensure that the package is tightly closed. After sealing, the equipment will cut the excess material to make the finished product neatly packaged. - **Finished product output**: The packaged perfume box is sent out via a conveyor belt, and workers can put it directly into a carton or other outer packaging for further logistics and sales. ### 3. **Operation and control** - **Semi-automatic operation**: Unlike fully automatic equipment, semi-automatic cigarette packaging machines still rely on manual operation, especially in the feeding and final inspection links. Workers need to manually place the perfume bottles into the machine's feed port and perform quality checks after packaging. - **Simple control interface**: Usually equipped with a simple control panel, workers can adjust parameters such as packaging speed, film length, heat sealing temperature, etc. through buttons or touch screens to adapt to the packaging requirements of perfume bottles or boxes of different specifications. - **High adjustability**: Due to the variety of sizes of perfume bottles and packaging boxes, semi-automatic cigarette packaging machines are usually designed to be highly adjustable and can flexibly adapt to product packaging of different sizes. |

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation: 1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

HENWI TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

Bldg 3, Gaoyi Industrial Park, No.5 Shangbai Rd., 528226 Shishan town, Nanhai Dist, Foshan City, P.R., China

About Us

We are a professional cosmetic, pharm and food machinery production, sales and related technical services of modern high-tech enterprises.